To choose the right heat sealer, you must first define your specific packaging needs. The decision hinges on four critical factors: the type and thickness of the material you are sealing, your required production volume, operational constraints like space and energy, and the long-term cost versus the initial price.

The most effective heat sealer is not the most expensive or feature-rich model, but the one that aligns perfectly with the demands of your material, your workflow, and your operational scale.

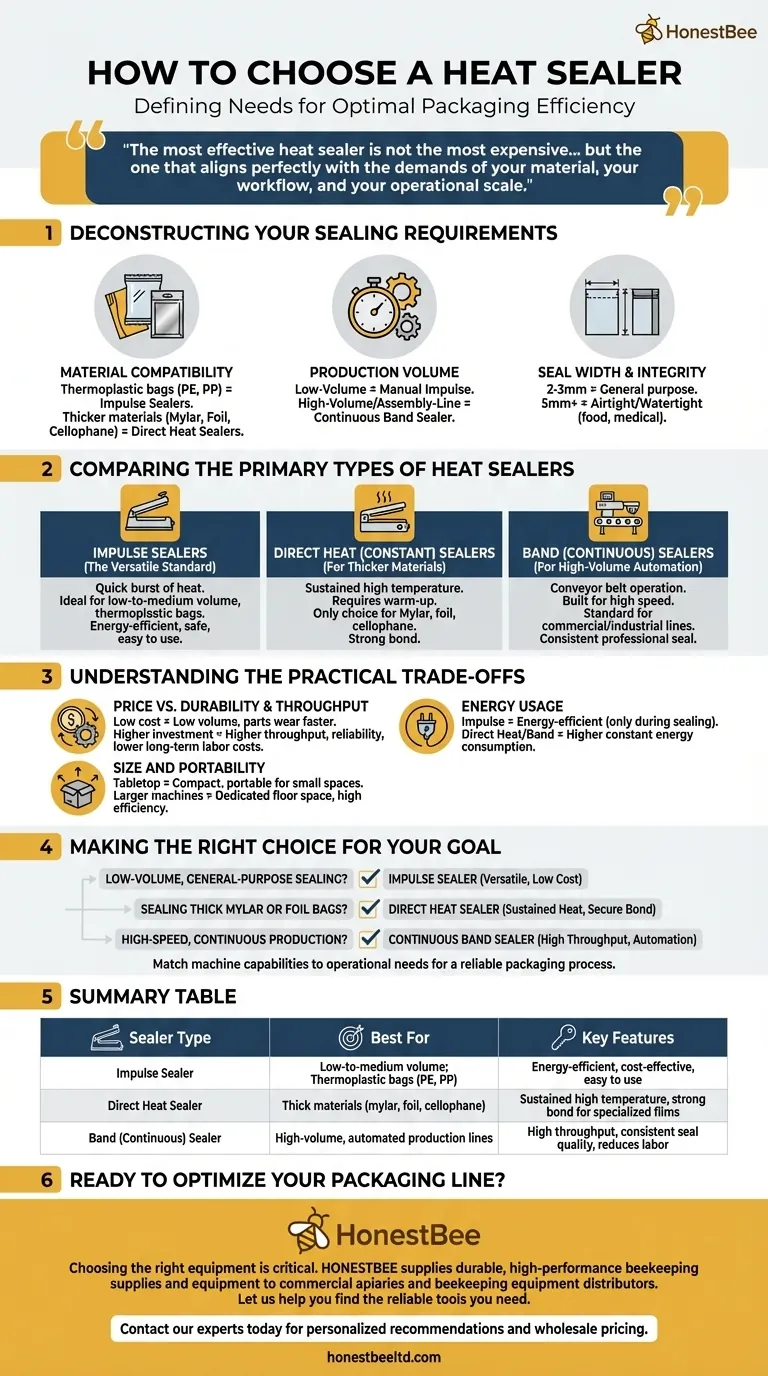

Deconstructing Your Sealing Requirements

Before comparing machines, you must have a clear picture of your project's technical and operational needs. Answering these questions first prevents costly purchasing errors.

Material Compatibility is Non-Negotiable

The primary factor is the material you intend to seal. Different plastics and films melt at different temperatures and require different sealing methods.

Most common thermoplastic bags, such as polyethylene (PE) and polypropylene (PP), are well-suited for standard impulse sealers.

Thicker materials, like mylar, foil-lined gusseted bags, or cellophane, require sustained high temperatures that only a direct heat sealer can provide.

Production Volume Dictates the Machine Type

Your daily or hourly sealing volume directly influences the type of sealer that will be most efficient for your operation.

For low-volume or occasional use, a manual impulse sealer is a cost-effective and reliable choice.

For high-volume, assembly-line-style operations, a continuous band sealer is necessary to keep pace with production and reduce manual labor.

The Seal Itself: Width and Integrity

The quality of the seal is paramount for product protection. The width and strength of the seal should match your application's requirements.

A standard 2-3mm seal is sufficient for general-purpose packaging. However, for products requiring an airtight or watertight closure, such as food or medical supplies, a wider seal (5mm or more) provides greater strength and integrity.

Comparing the Primary Types of Heat Sealers

Once you have defined your needs, you can effectively evaluate the main categories of heat sealers available.

Impulse Sealers: The Versatile Standard

Impulse sealers are the most common type. They use a quick burst of electricity to heat a wire element only when the sealing arm is closed, making them energy-efficient.

They are ideal for low-to-medium volume sealing of thermoplastic bags and are known for their ease of use and safety.

Direct Heat (Constant) Sealers: For Thicker Materials

Unlike impulse sealers, direct heat sealers maintain a consistently hot temperature in their sealing jaws. This requires a brief warm-up period.

Their sustained heat makes them the only choice for sealing thicker, specialized materials like mylar, foil, and cellophane that require more thermal energy to create a strong bond.

Band (Continuous) Sealers: For High-Volume Automation

Band sealers operate like a conveyor belt, moving bags through a heating and cooling process automatically. They are built for speed and efficiency.

These machines are the standard for commercial and industrial production lines, significantly increasing throughput and ensuring a consistent, professional-quality seal on every package.

Understanding the Practical Trade-offs

Choosing a heat sealer involves balancing initial cost with long-term performance and operational costs. Understanding these trade-offs is key to making a sound investment.

Price vs. Durability and Throughput

A low-cost manual sealer is a smart choice for a startup but will become a bottleneck as volume grows. Its parts may also wear out faster under heavy use.

Investing in a more durable or automated sealer costs more upfront but pays dividends through higher throughput, lower labor costs, and greater reliability over its lifespan.

Size and Portability

Tabletop impulse sealers are compact and can be easily stored or moved. This offers great flexibility for small workspaces or businesses with varied needs.

Larger machines like continuous band sealers require dedicated floor space and are a permanent fixture in a production line, trading portability for high-speed efficiency.

Energy Usage

Impulse sealers are highly energy-efficient, as they only draw power during the brief sealing cycle.

Direct heat and band sealers consume more energy because they must maintain a constant high temperature to operate, representing a higher ongoing operational cost.

Making the Right Choice for Your Goal

Select your heat sealer based on a clear-eyed assessment of your primary operational goal.

- If your primary focus is low-volume, general-purpose sealing: An impulse sealer offers the best combination of versatility, low cost, and energy efficiency.

- If your primary focus is sealing thick mylar or foil bags: A direct heat sealer is required to generate the sustained temperature needed for a secure bond.

- If your primary focus is high-speed, continuous production: A continuous band sealer is the only option that can provide the necessary throughput and automation.

By methodically matching the machine's capabilities to your specific operational needs, you ensure a reliable and efficient packaging process from day one.

Summary Table:

| Sealer Type | Best For | Key Features |

|---|---|---|

| Impulse Sealer | Low-to-medium volume; Thermoplastic bags (PE, PP) | Energy-efficient, cost-effective, easy to use |

| Direct Heat Sealer | Thick materials (mylar, foil, cellophane) | Sustained high temperature, strong bond for specialized films |

| Band (Continuous) Sealer | High-volume, automated production lines | High throughput, consistent seal quality, reduces labor |

Ready to Optimize Your Packaging Line?

Choosing the right equipment is critical for efficiency and product protection. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. We understand the demands of commercial-scale work.

Let us help you find the reliable tools you need to succeed. Contact our experts today for personalized recommendations and wholesale pricing.

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Professional Pneumatic Wire Embedder for Beehive Frames

- Professional Durable Plastic Handle Honey Uncapping Fork

People Also Ask

- What are the benefits of using packaging machines? Boost Efficiency, Cut Costs & Elevate Your Brand

- What are the different types of sealer machines? Find the Right Sealer for Your Operation

- What are the causes and solutions for leakage in a stick pack seal? Fix Pressure, Temperature, and Hardware Issues

- What is a sealing machine called? Choose the Right Heat Sealer for Your Packaging

- How is a heat sealer used in the production of honey sticks? Master the Art of Leak-Proof Sealing