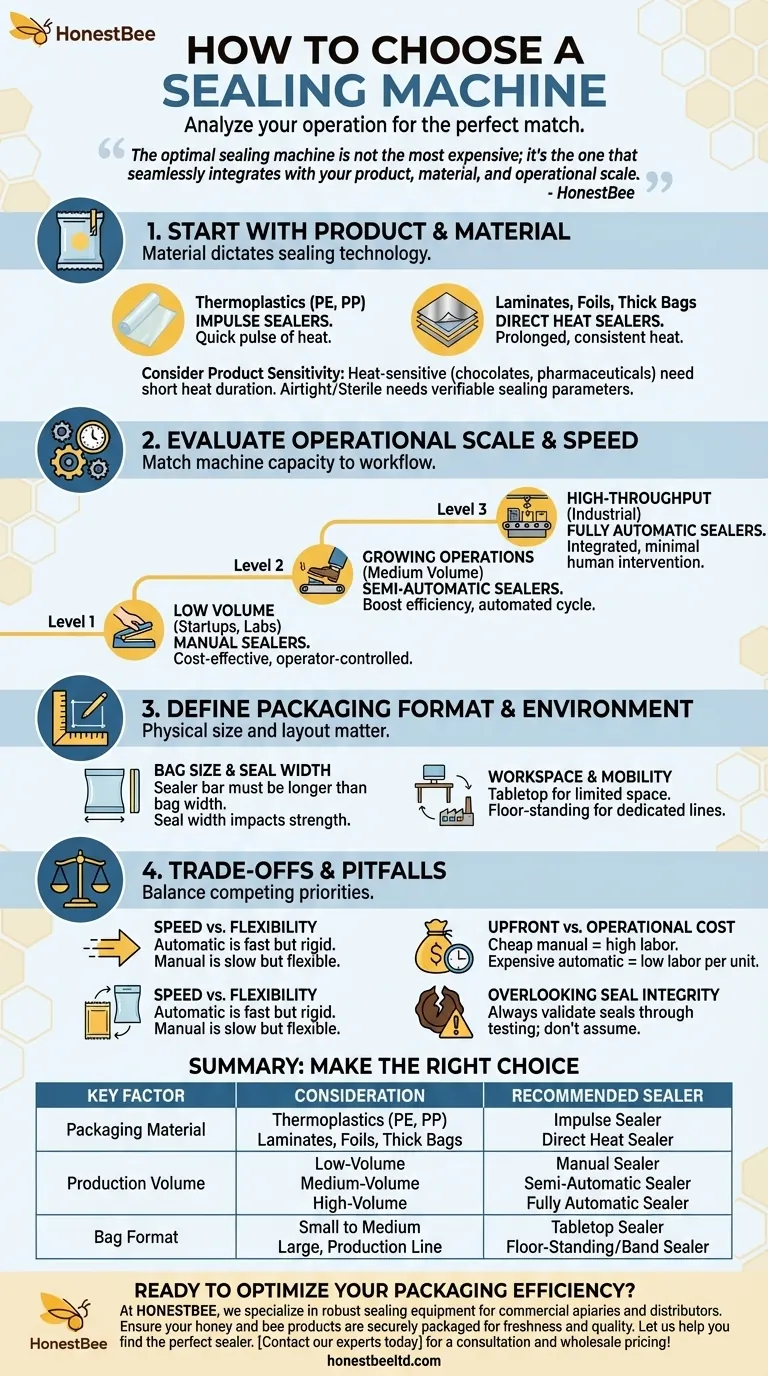

Choosing the right sealing machine requires you to look beyond the machine itself and analyze your entire packaging operation. The correct choice is determined by four key factors: the material you are sealing, your required production capacity, the physical format of your packages, and any need for mobility.

The optimal sealing machine is not the most expensive or feature-rich model; it is the one that seamlessly integrates with your specific product, packaging material, and operational scale. The decision is fundamentally about matching the technology to the job.

Start with Your Product and Material

The single most important factor is the material of your packaging film. The wrong sealing technology will result in weak or failed seals, compromising your product.

Matching Sealer Type to Film

Thermoplastics like Polyethylene (PE) and Polypropylene (PP) are common and work well with impulse sealers, which apply a quick pulse of heat. These are versatile for many basic applications.

More complex materials, such as laminates, foils, or thicker gusseted bags, often require prolonged, consistent heat. For these, a direct heat sealer (also called a constant heat sealer) is necessary to ensure the heat penetrates all layers.

Considering Product Sensitivity

If your product is heat-sensitive (like chocolates or certain pharmaceuticals), the speed of the seal is critical. An impulse sealer delivers heat for a very short duration, minimizing heat transfer to the package contents.

For products that require an airtight or sterile environment, the integrity and consistency of the seal are paramount. This may push you toward more advanced machines with verifiable sealing parameters.

Evaluate Your Operational Scale and Speed

Your required output dictates the level of automation you need. Mismatching machine capacity to your workflow creates bottlenecks or wastes capital.

Manual Sealers for Low-Volume Needs

For startups, lab testing, or small-batch production, a manual impulse sealer is the most cost-effective entry point. The operator controls every aspect of the sealing cycle.

Semi-Automatic for Growing Operations

As volume increases, a semi-automatic sealer (like a foot-pedal operated model or a continuous band sealer) offers a significant boost in efficiency. These machines automate the sealing cycle, freeing up the operator to simply position the bags.

Fully Automatic for High-Throughput

In a large-scale industrial setting, a fully automatic sealer is integrated into a production line. It handles bag feeding, sealing, and discharging with minimal human intervention, maximizing throughput.

Define Your Packaging Format and Environment

The physical size of your bags and the layout of your workspace will immediately narrow your options.

Bag Size and Seal Width

Sealers are rated for a maximum seal length. You must choose a machine with a sealing bar longer than the width of your widest bag. The width of the seal itself (e.g., 2mm, 5mm, 10mm) also impacts seal strength and aesthetics.

Workspace and Mobility

For applications like a farmer's market or a small, cramped kitchen, a compact tabletop sealer is ideal. If you have a dedicated packaging line, a larger, stationary band sealer or automatic system is more appropriate. Mobility is a key differentiator between tabletop models and larger, floor-standing units.

Understanding the Trade-offs and Common Pitfalls

Choosing a sealer involves balancing competing priorities. Being aware of these trade-offs will prevent costly mistakes.

Speed vs. Flexibility

Fully automatic systems are incredibly fast but are often configured for one specific bag size and type. Manual sealers are slow but offer maximum flexibility to switch between different packaging formats on the fly.

Upfront Cost vs. Operational Cost

A cheap manual sealer has a low initial cost but a high labor cost per unit. An expensive automated machine has a high upfront cost but dramatically reduces the labor cost per package and can run for longer shifts.

Overlooking Seal Integrity

The most common pitfall is assuming a seal is good just because it looks closed. A proper seal must be validated through testing (e.g., pressure tests, visual inspection) to ensure it protects the product, especially for food or medical items.

Making the Right Choice for Your Operation

Use your primary goal to guide your final decision.

- If your primary focus is low-volume startup or product testing: Choose a simple, low-cost manual impulse sealer that can handle your film type.

- If your primary focus is increasing output for a growing business: Invest in a semi-automatic machine like a continuous band sealer to boost speed and consistency.

- If your primary focus is high-volume industrial efficiency: A fully automatic sealer integrated into your production line is the only viable long-term solution.

Ultimately, defining your process first will make the right machine choice self-evident.

Summary Table:

| Key Factor | Consideration | Recommended Sealer Type |

|---|---|---|

| Packaging Material | Thermoplastics (PE, PP) | Impulse Sealer |

| Packaging Material | Laminates, Foils, Thick Bags | Direct Heat Sealer |

| Production Volume | Low-Volume (Startups, Labs) | Manual Sealer |

| Production Volume | Medium-Volume (Growing Business) | Semi-Automatic Sealer |

| Production Volume | High-Volume (Industrial) | Fully Automatic Sealer |

| Bag Format | Small to Medium Bags | Tabletop Sealer |

| Bag Format | Large Bags, Production Line | Floor-Standing/Band Sealer |

Ready to Optimize Your Packaging Efficiency?

Choosing the right sealing machine is critical for your product's integrity and your operation's profitability. At HONESTBEE, we specialize in supplying robust, reliable sealing equipment tailored for commercial apiaries and beekeeping equipment distributors.

Our range of sealing solutions ensures your honey, beeswax, and other bee-related products are securely packaged, maintaining freshness and quality from your facility to your customers.

Let us help you find the perfect sealer for your specific needs. Contact our experts today for a personalized consultation and wholesale pricing!

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- How does an induction sealing machine work? Enhance Honey Packaging with Hermetic Seals & Tamper Evidence

- What are the advantages of applying anti-counterfeiting stamp holograms to honey packaging? Protect Your Brand & Quality

- How does Vacuum Packing Equipment contribute to bee product value? Preserve Pollen Potency and Boost Retail Profits

- What is a sealing machine? Protect Your Product Quality and Brand Reputation

- What is a round seal on a honey stick pack? Elevate Your Branding with Custom Aesthetics

- Why is the selection of sealing materials critical in stingless bee hives? Enhance Hive Health and Pest Protection

- How do you package honey safely? Protect Your Harvest from Moisture and Contamination

- What defines a 4-side seal on a package? Discover the Benefits of Total Perimeter Sealing for Maximum Security