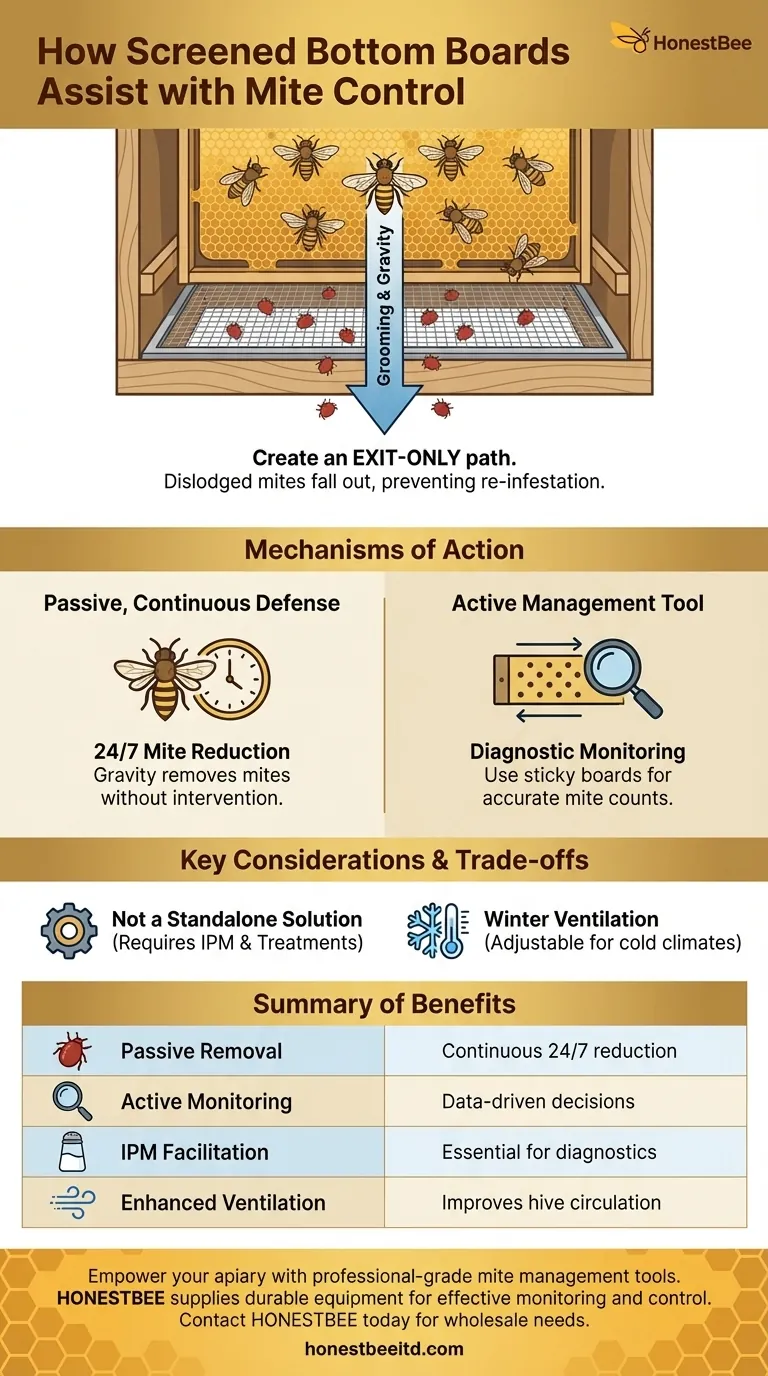

To put it simply, a screened bottom board helps with mite control by creating an exit-only path for Varroa mites. When mites are dislodged from a bee through natural grooming, they fall downwards. The screen allows these mites to fall completely out of the hive, preventing them from climbing back up and re-infesting another bee.

A screened bottom board is not a silver bullet for mite eradication, but rather a critical tool for both passive mite reduction and active population monitoring within an Integrated Pest Management (IPM) framework.

The Primary Mechanism: Breaking the Mite Cycle

A screened bottom board fundamentally changes the hive floor from a solid surface to a permeable barrier. This simple change has a significant impact on the Varroa mite's ability to thrive.

The "Grooming and Gravity" Effect

Bees are meticulous and constantly groom themselves and their hive mates. This grooming behavior can dislodge Varroa mites, which then lose their grip and fall.

On a traditional solid bottom board, a fallen mite can simply wait for a passing bee to climb onto, re-entering the population. A screened bottom board allows gravity to do the work, permanently removing that mite from the colony.

A Passive, Continuous Defense

This process works 24/7 without any intervention from the beekeeper. It provides a constant, low-level reduction of the mite population within the hive, which can help slow the overall growth of an infestation.

Using the Screen for Active Management

Beyond its passive function, the screened bottom board is an invaluable diagnostic tool. It enables beekeepers to accurately assess the mite threat without disrupting the colony.

The Sticky Board Count

By sliding a white, sticky board (often called a "mite board") under the screen, you can catch and count the mites that fall over a specific period, typically 24-72 hours.

This "mite drop count" is a primary method for estimating the severity of an infestation and determining if and when a more aggressive treatment is necessary.

Facilitating the Sugar-Shake Method

The screen is also essential for the "sugar-shake" or "powdered sugar roll" method. Beekeepers dust a sample of bees with powdered sugar, which encourages intense grooming and causes mites to fall off.

When this is done over a screened bottom, the mites and sugar fall through the mesh onto a collection board, providing a rapid snapshot of the colony's mite load.

Understanding the Trade-offs

While highly beneficial, a screened bottom board is a piece of equipment with specific considerations. It is a component of a strategy, not the entire strategy itself.

It Is Not a Standalone Solution

A screened bottom board assists in control but will not solve a heavy Varroa mite infestation on its own. It must be paired with regular monitoring and, when necessary, appropriate mite treatments.

Considerations for Winter

The increased ventilation from a screen can be beneficial for reducing moisture in the hive during winter. However, in extremely cold or windy climates, some beekeepers choose to slide an insert in to block the screen and help the colony conserve heat.

Making the Right Choice for Your Apiary

The decision to use a screened bottom board depends on your management goals and local climate.

- If your primary focus is Integrated Pest Management (IPM): A screened bottom board is an essential tool for monitoring mite levels and making data-driven treatment decisions.

- If your primary focus is simplifying hive management: The board offers a passive way to constantly reduce mite pressure without requiring frequent intervention.

- If you are a beekeeper in a hot, humid climate: The enhanced ventilation can significantly improve colony health and reduce stress during the summer.

Ultimately, a screened bottom board empowers you with crucial information, turning the invisible threat of mites into a measurable and manageable problem.

Summary Table:

| Function | Benefit for Beekeepers |

|---|---|

| Passive Mite Removal | Continuously reduces mite population via grooming and gravity, 24/7. |

| Active Monitoring | Enables accurate mite drop counts with a sticky board for data-driven decisions. |

| IPM Facilitation | Essential for diagnostic methods like the sugar-shake test. |

| Enhanced Ventilation | Improves hive air circulation, beneficial in hot and humid climates. |

Empower your apiary with professional-grade mite management tools.

A screened bottom board is a fundamental component of a successful Integrated Pest Management (IPM) strategy. For commercial apiaries and beekeeping equipment distributors, having reliable, high-quality equipment is non-negotiable for maintaining healthy, productive colonies.

HONESTBEE supplies the durable beekeeping supplies and equipment you need to effectively monitor and control Varroa mites. Our wholesale-focused operations are designed to meet the demands of serious beekeepers.

Contact HONESTBEE today to discuss your wholesale needs and learn how our equipment can strengthen your IPM program.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

- Boardman Entrance Bee Feeder Durable Galvanized Steel and Wood Construction for Beekeeping

- HONESTBEE Professional Frame Wiring Board and Jig

People Also Ask

- How do specialized sprayers or impregnated strips assist in Varroa mite control? Enhance Your Biocontrol Strategy

- Why is winter a good time to treat hives with Oxalic Acid? Maximize Varroa Mite Control with a Brood Break

- What are the recommended Varroa mite thresholds? Master Seasonal Treatment for Healthy Hives

- What are the roles of high-precision watchmaker tweezers and fine brushes in Varroa surveys? Improve Data Accuracy

- What are the advantages of using miticide mixtures for Varroa destructor? Effective Resistance Management Strategies

- Why is oxalic acid preferred for Varroa mite control? Secure Your Hive's Organic Purity and High Mite Kill Rates

- What is the importance of using certified medications for controlling Varroa mites? Protect Your Honey and Colony Health

- How do oxalic acid trickle and thymol-based agents function in winter Varroa control? Master Winter Mite Management