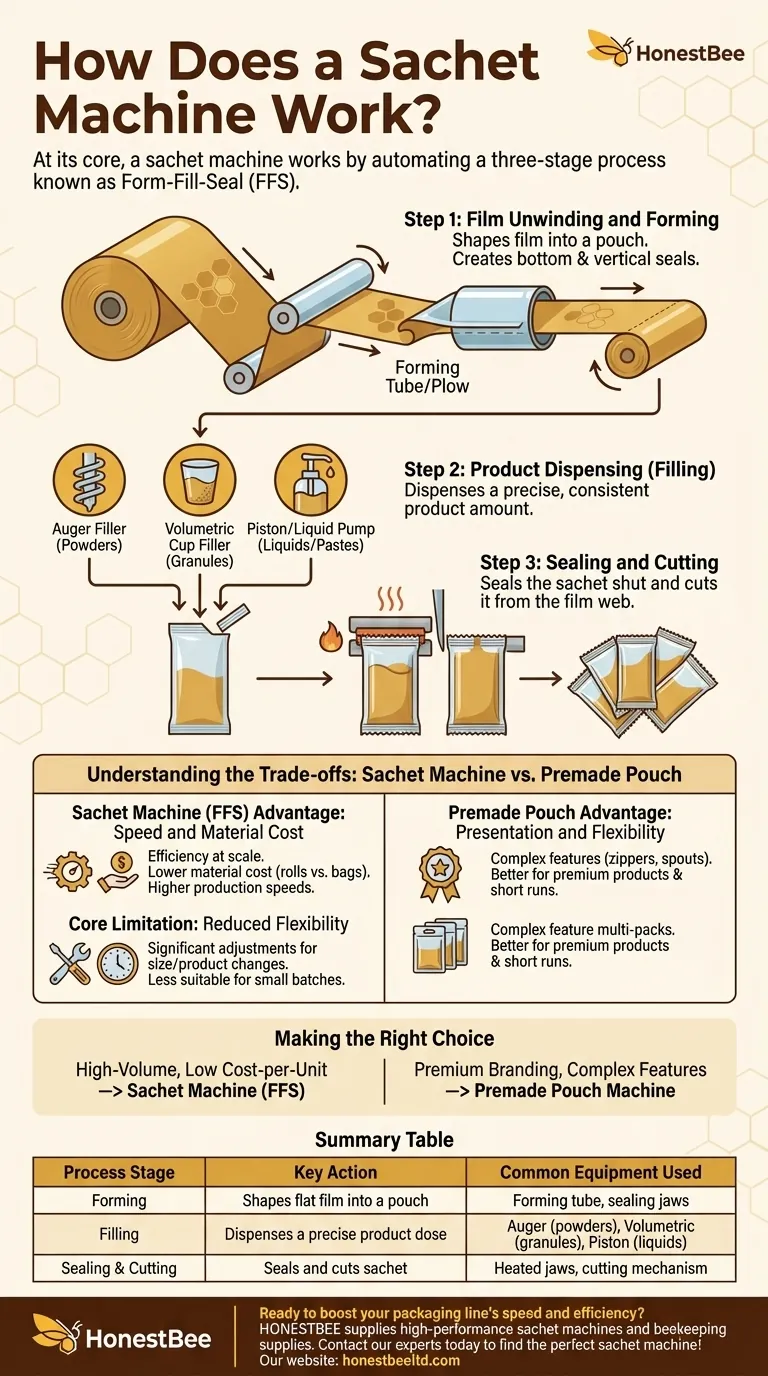

At its core, a sachet machine works by automating a three-stage process known as Form-Fill-Seal (FFS). It takes a continuous roll of flat, flexible film, shapes it into a pouch, dispenses a precise amount of product into it, and then seals it shut. This integrated system creates the package and fills it in one seamless, high-speed operation, ensuring product protection and production efficiency.

Understanding a sachet machine isn't just about the mechanics; it's about recognizing a highly integrated system. The machine simultaneously manufactures the package from raw film and fills it, a process that maximizes speed and minimizes material cost compared to systems that use pre-made bags.

The Step-by-Step Sachet Packaging Process

To truly grasp how a sachet machine operates, it's best to break down the Form-Fill-Seal cycle into its distinct, sequential actions.

Step 1: Film Unwinding and Forming

The process begins with a large roll of packaging film, often printed with branding, which is mounted on the machine.

This flat film is pulled off the roll and guided through a series of rollers. It then passes over a "forming tube" or "plow," which folds the flat film into the desired pouch shape, typically a tube. The machine then creates the bottom and vertical seals, forming an open-topped packet.

Step 2: Product Dispensing (Filling)

With the empty sachet formed and held in place, the machine's dosing system dispenses the product.

The type of dispenser depends on the product. An auger filler is used for powders, a volumetric cup filler for granules, and a piston or liquid pump is used for liquids and pastes. The machine ensures a precise and consistent amount is dispensed into every sachet.

Step 3: Sealing and Cutting

Once the sachet is filled, heated sealing jaws clamp down on the top of the pouch.

This action creates the final top seal, simultaneously forming the bottom seal of the next sachet in the continuous line of film. Finally, a cutting mechanism separates the completed, filled sachet from the film web.

Understanding the Trade-offs: Sachet Machine vs. Premade Pouch Machine

While a sachet machine creates the package from a roll, other systems use bags that are already manufactured. This distinction is critical.

The Sachet Machine Advantage: Speed and Material Cost

The primary advantage of a Form-Fill-Seal sachet machine is efficiency at scale.

Because it uses rolls of film instead of individual bags, the raw material cost per unit is significantly lower. The continuous motion also allows for much higher production speeds, making it ideal for mass-market products.

The Premade Pouch Advantage: Presentation and Flexibility

A premade pouch machine, by contrast, starts with fully formed bags. The machine simply opens, fills, and seals them.

These premade pouches can have more complex features like zippers, spouts, and high-quality graphics that are difficult to achieve on a standard sachet machine. This approach is often better for premium products or smaller production runs with frequent changeovers.

The Core Limitation to Consider

The main trade-off for a sachet machine's speed is reduced flexibility. Changing the sachet size or product type often requires significant mechanical adjustments and downtime, making it less suitable for highly varied, small-batch production.

Making the Right Choice for Your Goal

The decision between packaging systems comes down to your primary operational driver.

- If your primary focus is high-volume production and the lowest possible cost-per-unit: A Form-Fill-Seal sachet machine is the definitive choice for its speed and material efficiency.

- If your primary focus is premium branding, complex pouch features, or producing varied products in smaller batches: A premade pouch packaging machine offers superior flexibility and presentation quality.

By understanding this fundamental process, you can confidently select the packaging technology that aligns directly with your operational and brand objectives.

Summary Table:

| Process Stage | Key Action | Common Equipment Used |

|---|---|---|

| Forming | Shapes flat film into a pouch | Forming tube, sealing jaws |

| Filling | Dispenses a precise product dose | Auger filler (powders), Volumetric cup (granules), Piston pump (liquids) |

| Sealing & Cutting | Seals the sachet shut and cuts it from the film | Heated jaws, cutting mechanism |

Ready to boost your packaging line's speed and efficiency?

HONESTBEE supplies high-performance sachet machines and beekeeping supplies to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable, high-volume packaging equipment you need to scale your production.

Contact our experts today to find the perfect sachet machine for your operation!

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Professional Durable Customizable Blister Packing Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

People Also Ask

- What are the advantages of thermosonication technology? Superior Processing for Stingless Bee Honey Preservation

- Why is a high-precision electronic analytical balance required for the weighing of honey samples? Ensure Accurate Testing

- What are the requirements for temperature-controlled storage equipment for honey? Maximize Stability & Quality

- What happens to the honey after it is extracted? A Beekeeper's Guide to Post-Harvest Processing

- What advantages do modern honey harvesting techniques offer? Boost Yield and Purity with Specialized Machinery

- What factors can affect the efficiency and quality of the packaging process? Optimize Your Production Workflow

- What advantages do small-scale honey processing machines offer to hobbyists? Professionalize Your Local Honey Sales

- How do pH meters and acidity titration equipment identify honey quality? Ensure Purity & Botanical Authenticity