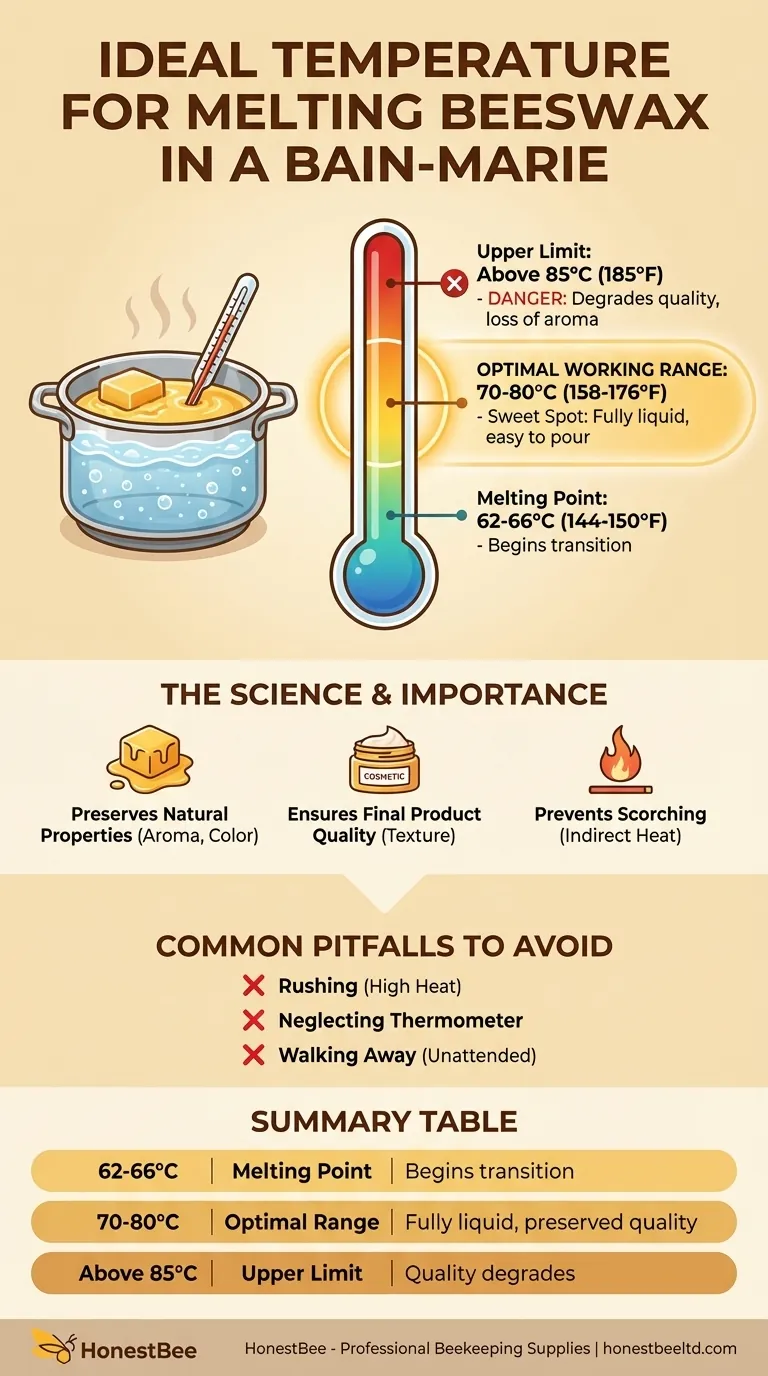

To melt beeswax properly in a bain-marie, the ideal temperature is between 70-80°C (158-176°F). Your primary goal is to exceed its melting point of around 64°C (147°F) to ensure it is fully liquid, but you must not let it surpass 85°C (185°F) to avoid degrading its quality.

The core principle of melting beeswax is control, not speed. Using a bain-marie (double boiler) with a thermometer allows you to gently liquify the wax without scorching it, which preserves its natural color, aroma, and structural integrity.

The Science of Melting Beeswax

Understanding the key temperature milestones is essential for achieving consistent, high-quality results. Each stage has a distinct impact on the final product.

The Melting Point: 62-66°C (144-150°F)

This is the temperature at which beeswax begins its transition from a solid to a liquid. While the wax will start to melt, it may not be fully liquified or at an ideal consistency for pouring.

The Optimal Working Range: 70-80°C (158-176°F)

This is the "sweet spot." In this range, the beeswax is completely melted, has a low viscosity, and is easy to pour for projects like candles, balms, or polishes. It provides a margin of safety, ensuring the wax is hot enough to work with but not hot enough to be damaged.

The Upper Limit: Above 85°C (185°F)

Exceeding this temperature is where problems begin. While the flashpoint of beeswax is much higher (around 204°C / 400°F), overheating to this degree will degrade the wax, causing it to lose its delicate aroma and potentially darken in color.

Why Precise Temperature Control is Crucial

Maintaining the right temperature isn't just about melting; it's about preserving the unique qualities of the beeswax.

Preserving Natural Properties

The subtle, sweet aroma of beeswax is one of its most valued characteristics. Overheating can burn off these volatile compounds, leaving you with a less pleasant or even scorched smell.

Ensuring Final Product Quality

For projects like rolled beeswax sheets or cosmetics, overheating can alter the wax's crystalline structure. This can affect the texture, pliability, and overall performance of your finished product.

Preventing Scorching and Hotspots

Using a bain-marie provides indirect, even heat. This is non-negotiable. Placing a pot of beeswax directly on a heat source creates hotspots that will easily scorch the wax at the bottom long before the top has melted.

Common Pitfalls to Avoid

Success often comes from knowing what not to do. Be mindful of these common mistakes that can compromise your results.

Rushing the Process

The most common mistake is using high heat to speed up the melting process. Beeswax should be melted slowly and gently with the water in the bain-marie at a light simmer, not a rolling boil.

Neglecting a Thermometer

While watching the water simmer is a good visual guide, it is not a substitute for data. A simple candy or craft thermometer is the only way to know the exact temperature of your wax and ensure you stay within the optimal range.

Walking Away from Melting Wax

Never leave melting wax unattended. It is a flammable material, and though a bain-marie is a safe method, attentiveness is a critical part of the process.

Making the Right Choice for Your Goal

Your ideal temperature depends on your specific application. Use these guidelines to dial in your process.

- If your primary focus is on cosmetics or lip balms: Aim for the lower end of the working range, around 70°C (158°F), to best preserve the delicate aroma and beneficial properties.

- If your primary focus is on candle making: A temperature of 75-80°C (167-176°F) ensures the wax is fully liquid for smooth, even pouring and proper adhesion to the wick.

- If you are a beginner: Prioritize safety and consistency by using a thermometer and never allowing the wax to exceed 80°C (176°F).

Mastering temperature control is the key to unlocking the full potential of your beeswax projects.

Summary Table:

| Temperature Range | Status & Key Characteristic |

|---|---|

| 62-66°C (144-150°F) | Melting Point: Wax begins to transition from solid to liquid. |

| 70-80°C (158-176°F) | Optimal Working Range: Wax is fully liquid, easy to pour, and quality is preserved. |

| Above 85°C (185°F) | Upper Limit / Danger Zone: Wax quality degrades; aroma and color can be damaged. |

Need reliable, high-quality beekeeping supplies for your operation? As HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the durable, professional-grade tools they need to succeed. From high-capacity melting tanks to precision thermometers, our wholesale-focused operations are designed to support your business's growth and efficiency. Contact our team today to discuss your needs and discover the HONESTBEE advantage.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the advantages of using industrial wax melters for beeswax? Achieve Scalable, Safe, and Consistent Production

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods