At its core, a bottle sealing machine works by using a non-contact process called electromagnetic induction. The machine's sealing head generates a controlled energy field that heats a specialized foil liner inside the bottle cap, melting a polymer layer on the liner. The pressure from the tightened cap then fuses this melted polymer onto the rim of the container, creating a perfect, airtight seal.

The fundamental principle isn't just about applying heat; it's about using a targeted electromagnetic field to create a welded, hermetic barrier. This method guarantees product integrity without direct contact, ensuring freshness, safety, and tamper evidence.

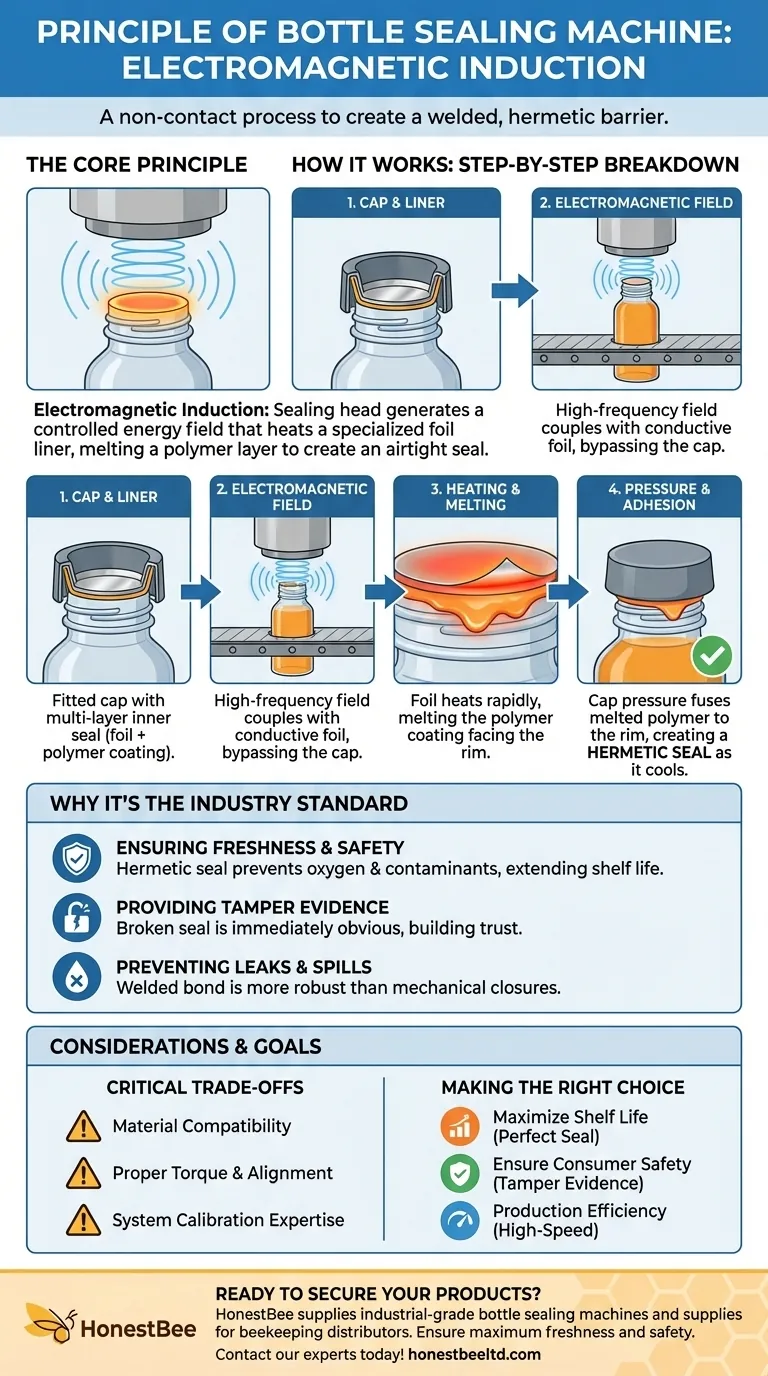

How Induction Sealing Works: A Step-by-Step Breakdown

To understand the principle, it's best to visualize the process as a sequence of precise events that happen in seconds as a bottle passes under the sealing head on a conveyor line.

The Key Components: Cap and Liner

Before the sealing process can begin, the container must be fitted with a cap containing a multi-layer inner seal. This liner is typically composed of a foil layer and a heat-activated polymer coating.

The Electromagnetic Field

As the capped bottle passes under the sealing head, the system generates a high-frequency electromagnetic field. This field penetrates the cap without heating it.

Think of this like a wireless charger for the foil liner. The energy passes harmlessly through the plastic cap and couples directly with the conductive foil material.

The Heating and Melting Process

The electromagnetic energy causes the foil liner to heat up rapidly. This intense, localized heat melts the polymer coating that faces the container's rim.

The process is incredibly fast and controlled, ensuring that only the sealant melts without affecting the product inside or the cap itself.

The Final Bond: Pressure and Adhesion

Simultaneously, the pressure from the already-tightened cap pushes the melted polymer layer firmly against the lip of the bottle or jar.

This combination of heat and pressure causes the polymer to fuse with the container's rim. As it cools, it forms a strong, uniform, and hermetic seal—a complete barrier to the outside environment.

Why This Principle is the Industry Standard

Induction sealing is not just one option among many; it is the dominant technology in industries from food and beverage to pharmaceuticals for several critical reasons.

Ensuring Product Freshness and Safety

The hermetic seal created by this process prevents oxygen, moisture, and other contaminants from entering the container. This directly extends shelf life and maintains the product's intended quality and safety.

Providing Tamper Evidence

A key benefit is the creation of a tamper-evident barrier. If the seal is broken or removed, it is immediately obvious to the consumer that the product may have been compromised, which builds significant trust.

Preventing Leaks and Spills

The welded bond is far more robust than a simple mechanical closure. This prevents costly and messy leaks during shipping and handling, protecting both the product and its surrounding packages.

Understanding the Trade-offs and Considerations

While highly effective, the principle of induction sealing relies on a precisely controlled system. Understanding its limitations is key to successful implementation.

Material Compatibility is Non-Negotiable

This process only works with the correct combination of materials. You must use caps fitted with induction-ready liners and ensure they are compatible with the container material (e.g., PET, HDPE, PP, or glass).

Proper Torque and Alignment are Critical

The cap must be applied with the correct amount of torque. If it's too loose, there won't be enough pressure to form a bond. If it's too tight, it can damage the liner or threads. The container must also be correctly aligned under the sealing head.

System Calibration Requires Expertise

Achieving a perfect seal requires dialing in the right settings on the machine. Factors like the output power of the sealing head and the speed of the conveyor belt must be carefully balanced. Too much power can burn the liner; too little will result in a weak or incomplete seal.

Making the Right Choice for Your Goal

To apply this technology effectively, align your operational setup with your primary objective.

- If your primary focus is maximizing shelf life: Prioritize achieving a perfect, continuous hermetic seal by meticulously testing your liner, container, and machine settings.

- If your primary focus is ensuring consumer safety: Emphasize the tamper-evident feature in your packaging and marketing, as a broken seal is the clearest indicator of potential compromise.

- If your primary focus is production efficiency: Leverage the high-speed, non-contact nature of induction sealing to increase throughput, but invest in regular calibration to minimize faulty seals and downtime.

Ultimately, the principle of induction sealing provides a reliable method for transforming a simple container into a secure, trusted, and preserved product.

Summary Table:

| Key Principle | How It Works | Key Benefit |

|---|---|---|

| Electromagnetic Induction | Generates a field that heats a foil liner inside the cap, melting a polymer layer. | Non-contact, rapid, and precise sealing. |

| Heat and Pressure Fusion | The melted polymer fuses to the container rim under cap pressure, creating a bond. | Creates a strong, hermetic, and airtight barrier. |

| Tamper Evidence | The seal must be broken to open the container, showing clear evidence of tampering. | Ensures consumer safety and builds trust. |

Ready to secure your products with reliable, high-speed induction sealing?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with industrial-grade bottle sealing machines and compatible supplies. Our equipment ensures your honey, syrups, and other products are perfectly sealed for maximum freshness, safety, and shelf life.

Contact our experts today to find the right sealing solution for your high-volume production needs. Let us help you protect your brand and deliver trusted products to your customers.

Visual Guide

Related Products

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Semi Automatic Electric Bottle Capping Machine

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

People Also Ask

- What is the function of semi-automatic heat shrink packaging machines in a glass jar reuse facility? Protect Your Inventory

- What is a bottle cap sealing machine? The Key to Automated, Tamper-Evident Packaging

- What role does proper sealing play in preventing honey contamination? Secure Pure Quality & Hygiene Standards

- Why are food-grade sterile containers and professional sealing equipment required for honey storage? Protect Your Quality

- What advantages does automatic filling and sealing equipment provide? Achieve Precision in Honey Packaging

- How does the application of sealing tape to hive gaps contribute to stingless bee colonies? Boost Growth & Defense

- What are the different types of sealer machines? Find the Right Sealer for Your Operation

- What are the advantages of using vacuum filling machines and heat-sealing caps for bee pollen? Maximize Freshness Now