Testing honey at multiple stages of production is the fundamental practice that ensures its quality, safety, and long-term stability. While tasting is a part of the process, true quality control relies on objective measurements to verify the honey meets critical standards, especially when it will be stored for months before jarring and consumption.

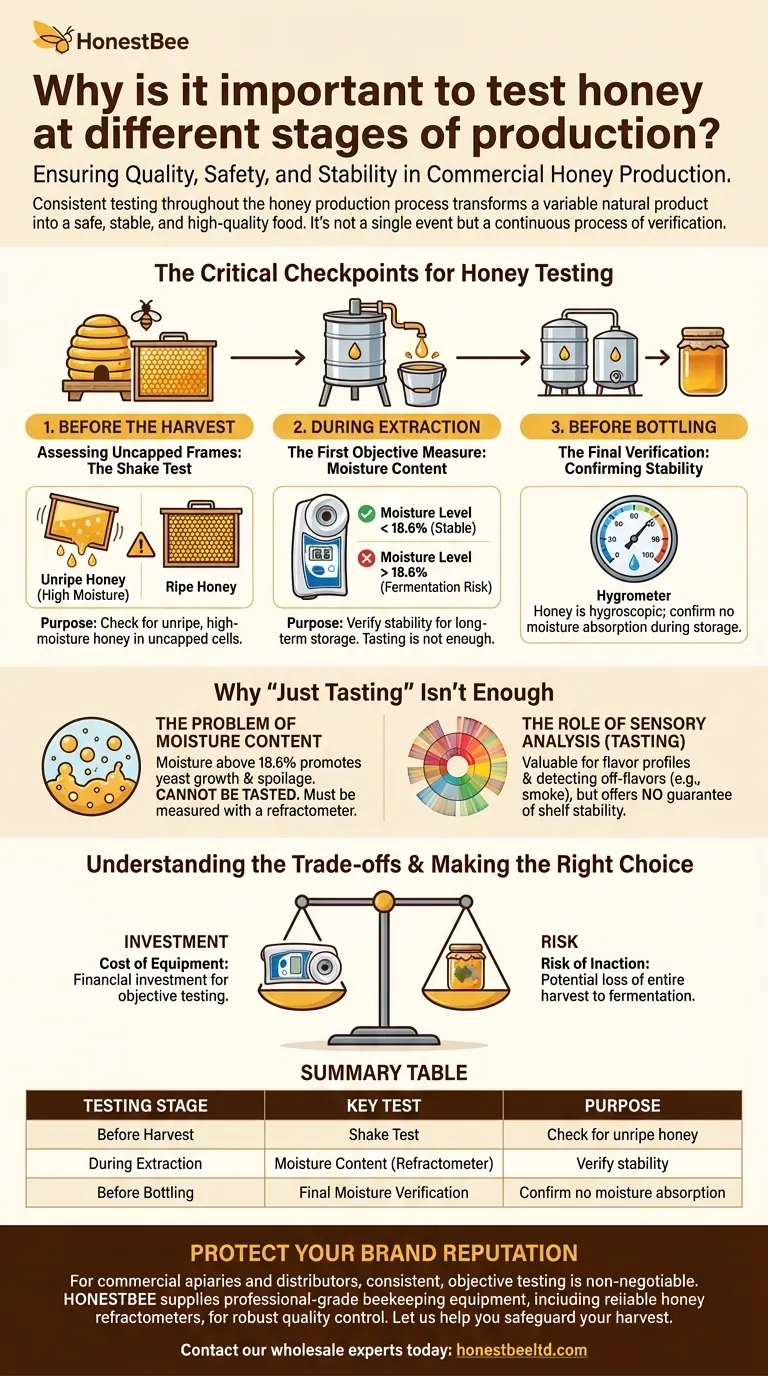

Consistent testing throughout the honey production process transforms a variable natural product into a safe, stable, and high-quality food. It's not a single event but a continuous process of verification, moving beyond simple taste to objective measures of moisture content and purity.

The Critical Checkpoints for Honey Testing

Testing isn't a single action but a series of checks performed at key moments. Each stage presents a unique opportunity to identify potential issues before they compromise the entire batch.

Before the Harvest: Assessing Uncapped Frames

The first quality check happens in the hive. Honey is considered "ripe" when the bees have reduced its water content and capped the honeycomb cell with wax.

Uncapped or partially capped frames may contain "nectar" with high moisture content. Harvesting this unripe honey is the single biggest cause of fermentation later on. A simple field check involves turning a frame horizontally and giving it a firm shake. If liquid drips out, the honey is not yet ready for harvest.

During Extraction: The First Objective Measure

This is the most critical testing point. As honey flows from the extractor, its properties can be measured accurately for the first time.

While tasting for off-flavors is common, the essential test here is for moisture content. This is done using a tool called a honey refractometer. This measurement provides a definitive answer on whether the honey is stable enough for long-term storage.

Post-Extraction and Before Bottling: The Final Verification

Honey is hygroscopic, meaning it can absorb moisture from the air. If honey is stored in an unsealed container in a humid environment, its moisture content can rise over time.

For this reason, a final test before jarring is a professional best practice. This final check confirms that the honey has remained stable during storage and is ready for the consumer, preventing any risk of fermentation after it has been bottled and sold.

Why "Just Tasting" Isn't Enough

Sensory analysis, or tasting, is valuable for identifying flavor profiles and detecting obvious issues like smoke taint. However, it cannot identify the most significant threat to your honey's quality.

The Problem of Moisture Content

The single most important factor for honey stability is its moisture content. Honey with a moisture level above 18.6% provides a hospitable environment for naturally occurring osmophilic yeasts to grow.

This growth leads to fermentation, spoiling the honey's flavor, aroma, and texture. You cannot taste an unsafe moisture level; it can only be measured with a refractometer.

The Role of Sensory Analysis (Tasting)

Tasting should be viewed as a complementary tool, not the primary method of quality control. It helps you understand the unique floral notes and characteristics of your harvest.

It is excellent for identifying undesirable flavors, such as those caused by overheating, contamination, or smoke from the bee smoker. However, it offers no guarantee of shelf stability.

Understanding the Trade-offs

Implementing a testing protocol involves balancing investment against risk.

The Cost of Equipment

The primary tool for objective testing, a honey refractometer, represents a financial investment. For a hobbyist producing a small amount for personal use, this cost may seem significant.

The Risk of Inaction

The alternative to testing is accepting risk. The cost of not testing is the potential loss of an entire harvest to fermentation. For anyone selling honey or storing it for extended periods, a single spoiled batch often costs more than the testing equipment.

Making the Right Choice for Your Goal

Your approach to testing should align directly with what you intend to do with your honey.

- If your primary focus is personal use or small gifts: The "shake test" before harvest and careful tasting may be sufficient, but you accept a higher risk of fermentation in storage.

- If your primary focus is selling at a market or ensuring long-term storage: Investing in a honey refractometer to test moisture content at extraction and before bottling is non-negotiable for product safety and reputation.

- If your primary focus is building a brand reputation: Consistent moisture testing combined with careful sensory analysis for flavor consistency is essential for delivering a reliable product every time.

Ultimately, diligent testing puts you in complete control of your final product's quality and safety.

Summary Table:

| Testing Stage | Key Test | Purpose |

|---|---|---|

| Before Harvest | Shake Test (Uncapped Frames) | Check for unripe, high-moisture honey |

| During Extraction | Moisture Content (Refractometer) | Verify stability for long-term storage |

| Before Bottling | Final Moisture Verification | Confirm no moisture absorption during storage |

Ensure every batch of your honey meets the highest standards of quality and safety.

For commercial apiaries and distributors, consistent, objective testing is non-negotiable for protecting your product and your brand reputation. HONESTBEE supplies the professional-grade beekeeping equipment—including reliable honey refractometers—that you need to implement a robust quality control protocol.

Let us help you safeguard your harvest. Contact our wholesale experts today to discuss the right testing equipment for your operation.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- 10L Stainless Steel Electric Honey Press Machine

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the primary function of a desktop refractometer? Ensure Honey Quality and Prevent Fermentation

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability

- What is the principle and importance of using a refractometer for honey moisture? Ensure Quality & Prevent Fermentation

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success