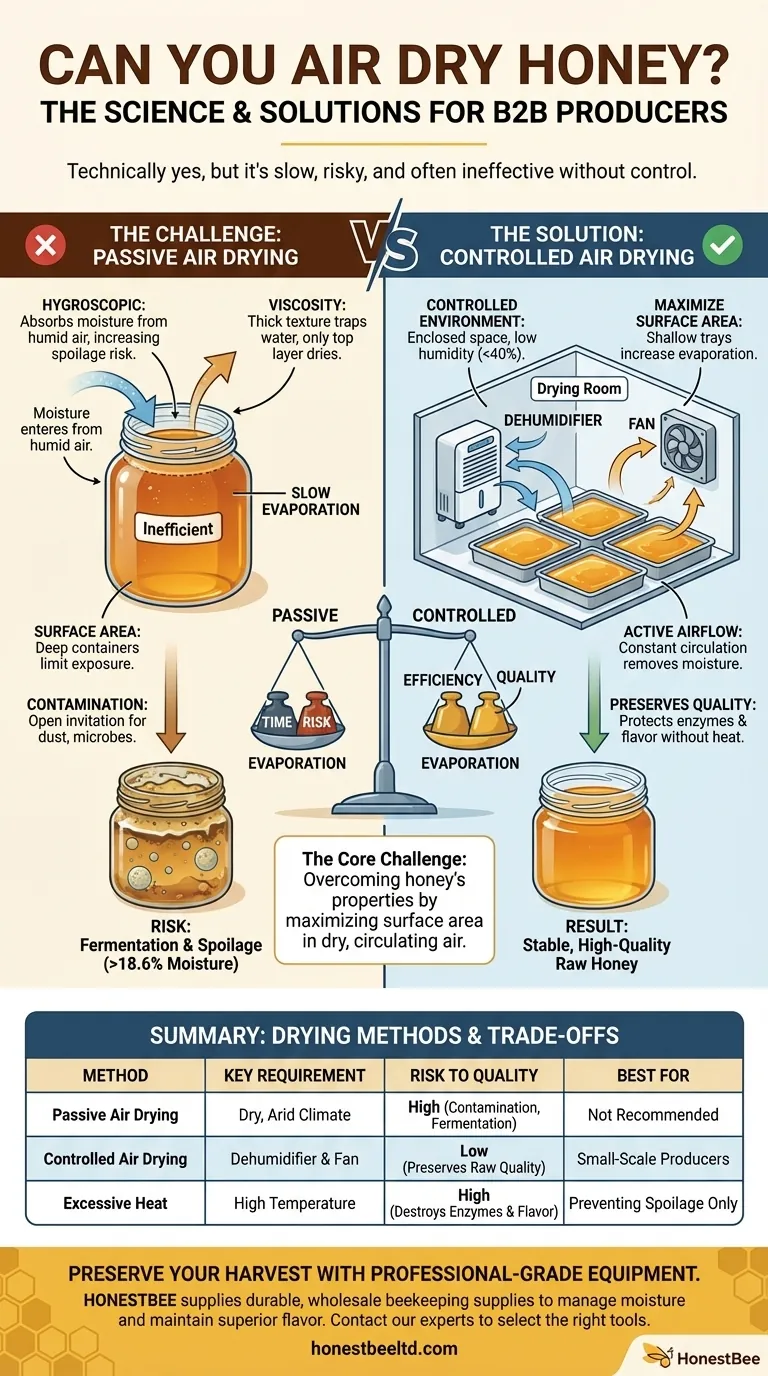

Technically, you can attempt to air dry honey, but it is an exceptionally slow, inefficient, and risky process. Due to honey's natural properties, simply exposing it to open air often fails to remove moisture and can even lead to contamination or further moisture absorption.

The core challenge in drying honey is not just exposing it to air, but controlling that air. To succeed, you must overcome honey's thick viscosity and its tendency to absorb ambient moisture by maximizing surface area while ensuring the surrounding air is both dry and circulating.

The Fundamental Challenge of Drying Honey

Understanding why honey is so difficult to dry is key to solving the problem correctly. It comes down to two of its inherent physical properties.

Honey is Hygroscopic

Honey naturally absorbs moisture from the surrounding environment. This means if you expose honey to air with moderate or high humidity, it will actually become wetter, not drier, increasing the risk of spoilage.

The Problem of Viscosity

Honey is a thick, viscous liquid. This thickness makes it very difficult for water molecules trapped deep within the honey to migrate to the surface where they can evaporate. Only the very top layer is actively drying.

Why High Moisture is a Risk

Honey with a water content above approximately 18.6% is susceptible to fermentation by naturally occurring yeasts. This will spoil the flavor, aroma, and shelf-stability of your entire batch.

Why Simple "Air Drying" is Ineffective

The common-sense approach of placing a container of honey out to "air dry" is destined to fail for several critical reasons.

The Surface Area Limitation

As the provided information notes, the deeper the container, the less surface area is exposed to air. In a typical bucket or jar, only a tiny fraction of the honey is in contact with the air, making any evaporation infinitesimally slow.

The High Risk of Contamination

Leaving honey open to the air for the days or weeks required for this passive method is an open invitation for dust, pollen, insects, and airborne microbes to contaminate your harvest.

The Overwhelming Impact of Humidity

Unless you live in an exceptionally arid climate, the ambient humidity will prevent effective drying. On a humid day, this method will actively harm your honey by increasing its water content.

Understanding the Trade-offs of Drying Methods

Every method for reducing moisture involves a trade-off between speed, effort, and the final quality of the honey.

The Pitfall of Passive Air Drying

The main trade-off here is time vs. risk. You are betting that the tiny amount of evaporation that occurs will happen before wild yeasts begin to ferment the honey. It is a gamble that is rarely worth taking.

The Danger of Excessive Heat

Using high heat is the fastest way to drive off water, but it comes at a steep cost. As noted in industrial methods, heating honey will darken its color, destroy delicate enzymes, and eliminate the subtle aromatic compounds that define its flavor. It effectively "cooks" the honey, stripping it of its raw qualities.

A Practical Approach: Controlled Air Drying

The most effective method for small-scale producers is not passive air drying, but active air drying. This involves creating a controlled environment.

Create a "Drying Room"

The goal is to place the honey in a small, enclosed space, like a closet or a large sealed box. The key is to control the air within that space.

Maximize Surface Area

Pour the honey into shallow, flat containers like food-safe bus tubs, baking sheets, or pans. This dramatically increases the surface area-to-volume ratio, which is critical for efficient evaporation.

Introduce a Dehumidifier and a Fan

Place a dehumidifier in the enclosed space to force the relative humidity down to very low levels (e.g., below 40%). Add a small fan to circulate this dry air constantly over the surface of the honey. This combination actively pulls moisture from the honey and whisks it away.

How to Apply This to Your Honey

Your final decision should be based on your primary goal for the honey.

- If your primary focus is preserving raw honey quality: The controlled "drying room" method using a dehumidifier and fan is the superior choice, as it protects the honey's delicate enzymes and flavor.

- If your primary focus is simply preventing spoilage at all costs: Gentle, indirect, and carefully monitored heat can work, but accept that it will fundamentally alter the honey's character from a raw product to a processed one.

By actively managing airflow and humidity, you can effectively reduce your honey's moisture content while preserving the unique quality of your harvest.

Summary Table:

| Method | Key Requirement | Risk to Honey Quality | Best For |

|---|---|---|---|

| Passive Air Drying | Dry, arid climate | High (Contamination, Fermentation) | Not Recommended |

| Controlled Air Drying | Dehumidifier & Fan | Low (Preserves Raw Quality) | Small-Scale Producers |

| Excessive Heat | High Temperature | High (Destroys Enzymes & Flavor) | Preventing Spoilage Only |

Preserve Your Harvest with Professional-Grade Equipment

As a commercial apiary or distributor, protecting your honey's quality is critical for your brand and profitability. The right equipment makes all the difference. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies you need to efficiently manage moisture content and maintain the superior flavor of your raw honey.

Let our experts help you select the right tools for your operation. Contact HONESTBEE today to discuss your needs and ensure your honey meets the highest quality standards.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Stainless Steel Triangle Support Honey Strainer and Filters

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What is the primary role of industrial mechanical dehumidification equipment in the production of immature honey?

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- How do high-efficiency honey dehydration and filtration systems enhance honey quality and unit yield? Optimize Your Honey

- What is the main purpose of professional dehumidifiers in honey production? Achieve Premium Quality and Stability

- What is the primary function of a honey dryer? Master Moisture Control and Prevent Fermentation