The most reliable way to monitor melting beeswax is with a dedicated thermometer. The key is to ensure the temperature stays within a specific window—typically melting around 144-150°F (62-66°C) and never exceeding 170°F (77°C) to preserve its quality and prevent safety hazards.

The core principle is not just to melt the wax, but to control the heat. Precise temperature monitoring is essential for protecting the beeswax's natural color, aroma, and beneficial properties from being destroyed by overheating.

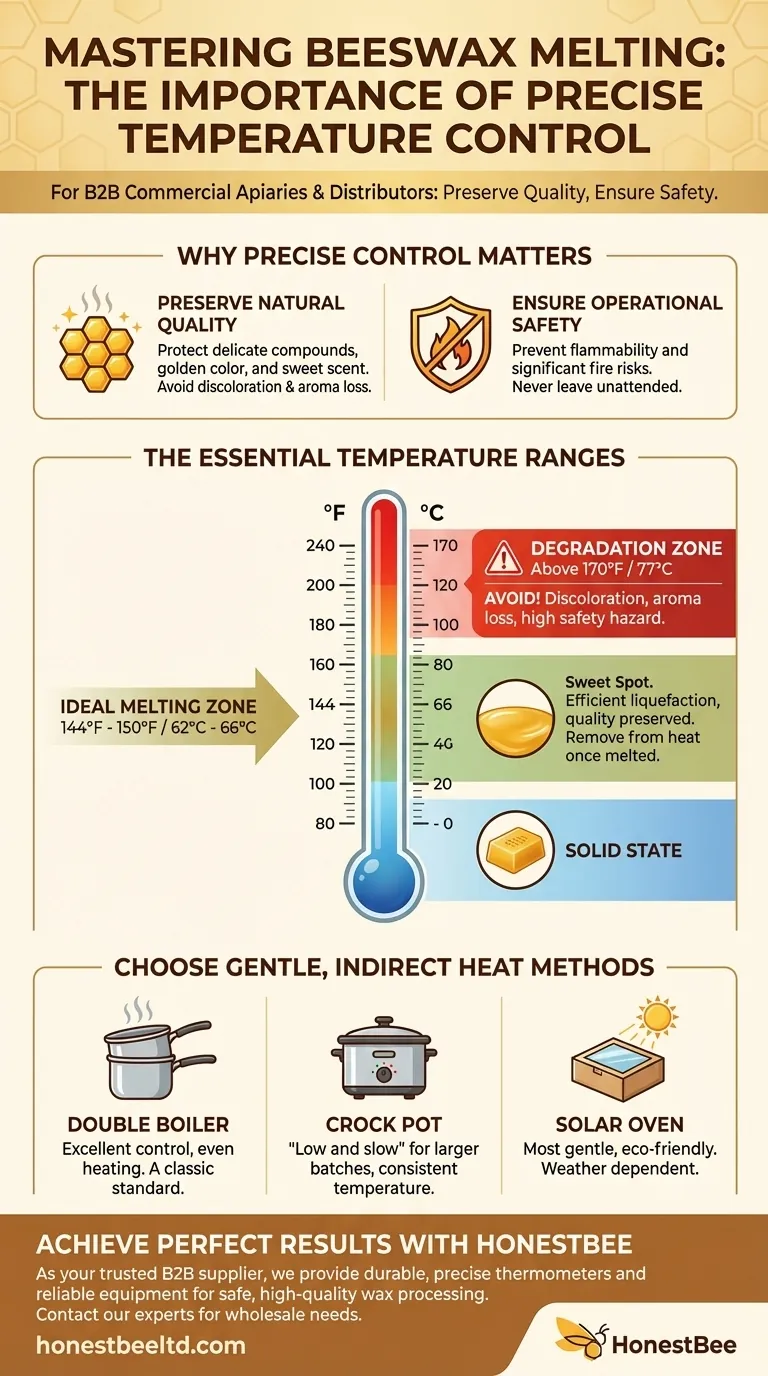

Why Precise Temperature Control is Critical

Simply melting beeswax isn't the goal; melting it correctly is. The temperature at which it melts has a direct impact on the final product's quality and your personal safety.

Preserving Natural Qualities

Beeswax contains delicate compounds that give it its characteristic sweet aroma and golden color. Heating it beyond 170°F (77°C) begins to break down these compounds.

This can result in a darker, discolored wax that has lost its pleasant, natural scent. Furthermore, some of its natural anti-microbial properties can be diminished by excessive heat.

Ensuring Safety

Beeswax is flammable. Heating it directly over an open flame or allowing it to get too hot can create a significant fire risk.

Using gentle, indirect heat and keeping the temperature below the 170°F threshold is a critical safety measure. You should also never leave melting wax unattended.

The Essential Temperature Ranges

Think of these numbers not as targets, but as boundaries. Your goal is to operate within this specific thermal window.

The Ideal Melting Zone: 144°F - 150°F

This is the sweet spot for melting beeswax. The wax will liquefy efficiently without damaging its inherent qualities. As soon as all solids are melted, you should remove the wax from the heat source.

The Degradation Zone: Above 170°F

This is the temperature to avoid. Once beeswax surpasses this point, discoloration and aroma loss become significant. The higher the temperature goes, the greater the damage and the higher the safety risk.

Choosing the Right Method for Gentle Heat

The method you use to melt the wax is just as important as the temperature you achieve. Direct heat is dangerous and difficult to control. Always opt for an indirect heating method.

The Double Boiler

This classic method uses boiling water to create steam, which then gently and evenly heats an upper pot containing the beeswax. It offers excellent control and is a standard for a reason.

The Crock Pot

A slow cooker or crock pot provides a "low and slow" heat source. This is a very safe, hands-off method for melting larger batches, as it's designed to maintain a consistent, low temperature over a long period.

The Solar Oven

Using a solar melter is the most gentle method of all. It leverages the sun's natural heat to slowly liquefy the wax. While effective, it offers the least control over the specific temperature and is dependent on weather conditions.

Making the Right Choice for Your Project

Your approach should be guided by your end goal. Use a dedicated thermometer and dedicated utensils for all beeswax work to avoid contamination and simplify cleanup.

- If your primary focus is preserving maximum aroma and color: Keep the temperature just high enough to melt the wax (around 145-150°F) and remove it from the heat as soon as it's fully liquid.

- If your primary focus is safety and simplicity: Use a crock pot or double boiler to guarantee indirect heat and prevent dangerous temperature spikes.

- If your primary focus is retaining all-natural properties: Never let the temperature exceed 170°F to protect the wax's delicate compounds and anti-microbial benefits.

By treating temperature not as a target but as a critical boundary, you ensure the integrity and safety of every project you undertake.

Summary Table:

| Temperature Range | Significance | Action |

|---|---|---|

| 144°F - 150°F (62°C - 66°C) | Ideal Melting Zone | Wax liquefies efficiently without damage. |

| Above 170°F (77°C) | Degradation Zone | Avoid! Risk of discoloration, aroma loss, and fire. |

Ready to achieve perfect results with every batch?

As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, precise thermometers and reliable equipment you need for safe, high-quality wax processing. Ensure your operation's efficiency and product integrity—contact our experts today to discuss your beekeeping supply needs!

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- 3D Square Honeycomb Pillar Silicone Candle Molds for Making Beeswax Candles

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards