To melt a bucket of crystallized honey, you must use gentle, prolonged heat to slowly reliquefy the sugar crystals without damaging the product. The ideal target temperature is around 40°C (104°F), applied consistently over one to two days. Rushing this process with high heat will cook the honey, destroying its delicate enzymes, aroma, and flavor.

Reliquefying honey is a balancing act between time and temperature. The core challenge isn't merely melting the honey, but doing so without causing heat damage. The safest and most effective strategy is always a low-and-slow approach that gently dissolves the crystals over an extended period.

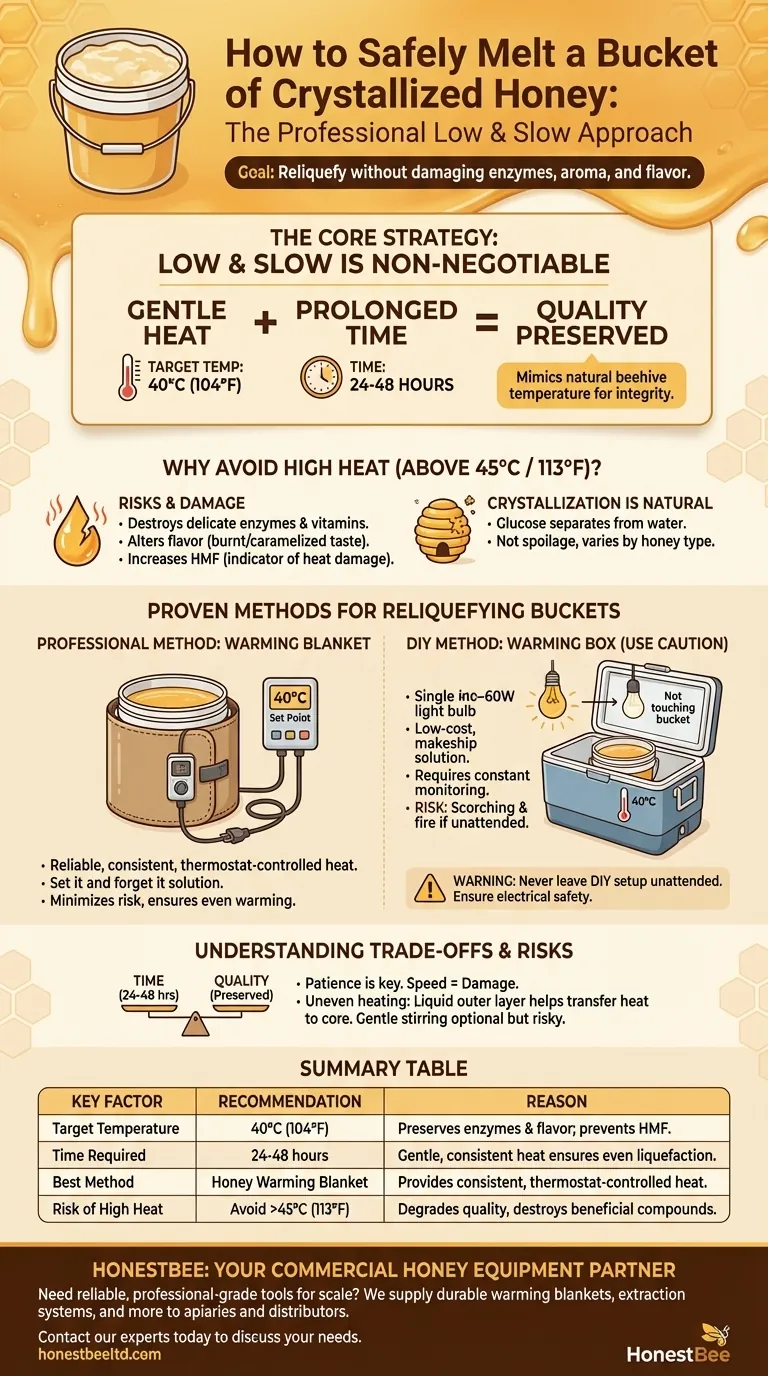

Why Low and Slow is Non-Negotiable

The Nature of Honey Crystallization

Crystallization is a natural process, not a sign of spoilage. It occurs when the glucose in honey separates from the water, forming solid sugar crystals.

This process happens at different rates depending on the honey's floral source, with some varieties crystallizing within weeks and others remaining liquid for years.

The Dangers of High Heat

Honey is a delicate, living food. Exposing it to temperatures above 45°C (113°F) begins to degrade its quality.

High heat destroys beneficial enzymes and vitamins. It also fundamentally alters the flavor and aroma, often giving it a slightly burnt or caramelized taste. Overheating also increases the levels of a compound called HMF (hydroxymethylfurfural), which is used as a key indicator of heat damage and poor quality in the honey industry.

The Ideal Temperature Range

The target temperature of 40°C (104°F) is the established benchmark for safely melting honey.

This temperature is warm enough to dissolve the glucose crystals but cool enough to preserve the honey's integrity. It closely mimics the natural temperature found inside a healthy, active beehive.

Proven Methods for Reliquefying Honey Buckets

The Professional Method: Warming Blankets

The most reliable method is to use a low-temperature heating band or blanket specifically designed for honey buckets. These are available from most beekeeping supply companies.

These blankets wrap around the bucket and have a built-in thermostat, ensuring a consistent and safe temperature. This is a "set it and forget it" solution that minimizes risk.

The DIY Method: A Warming Box

You can create a makeshift warming cabinet for a low-cost solution. Place the honey bucket inside an insulated container, like a large cooler or a sturdy cardboard box.

Introduce a gentle heat source, such as a single 40- to 60-watt incandescent light bulb secured in a safe ceramic fixture. Place a thermometer inside the box (not touching the bulb) to monitor the ambient temperature, ensuring it stays around 40°C (104°F).

Understanding the Trade-offs and Risks

Time vs. Quality

There is no way to rush this process without sacrificing quality. Any method promising to melt a five-gallon bucket in a few hours is using temperatures that will inevitably damage the honey. You must plan for a 24- to 48-hour timeframe.

DIY Fire and Safety Risks

The warming box method, while effective, carries inherent risks. Never leave a DIY heating setup unattended.

Ensure the light bulb is not touching the bucket or the walls of the box to prevent scorching and reduce fire risk. Using proper, stable electrical components is essential for safety.

Uneven Heating

The honey on the outside of the bucket will liquefy first. As the process continues, this liquid honey will help transfer heat toward the solid crystal core. While gentle stirring can speed this up slightly, it's often impractical and risks introducing contaminants. It's best to simply let time and gentle heat do the work.

Choosing the Right Method for Your Needs

The best approach depends on your commitment to the process and your long-term needs.

- If your primary focus is safety and repeatability: Invest in a dedicated honey warming blanket with a thermostat.

- If your primary focus is a low-cost, one-time solution: Carefully construct a DIY warming box, prioritizing safety and consistent temperature monitoring.

- If your primary focus is speed (and you accept the risk): This is not recommended, as any method faster than 24 hours for a full bucket will degrade the honey's quality.

Ultimately, patience is the most critical ingredient for successfully restoring your honey to its liquid state without compromise.

Summary Table:

| Key Factor | Recommendation | Reason |

|---|---|---|

| Target Temperature | 40°C (104°F) | Preserves enzymes and flavor; prevents HMF formation. |

| Time Required | 24-48 hours | Gentle, consistent heat ensures even liquefaction. |

| Best Method | Honey Warming Blanket | Provides consistent, thermostat-controlled heat. |

| Risk of High Heat | Avoid temperatures >45°C (113°F) | Degrades quality, destroys beneficial compounds. |

Need reliable equipment to process honey at scale while protecting its quality?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the professional-grade tools needed for efficient, safe honey handling—from warming blankets to full extraction systems. Our wholesale-focused operations ensure you get durable, purpose-built equipment that safeguards your product's integrity.

Contact our experts today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Steam Beeswax Melter Wax Warmer for Wax Processing

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- How does indirect heating equipment operating at 60°C to 70°C contribute to honey processing? Optimize Your Stability

- What are the benefits of a honey heating tank? Achieve Crystal-Clear, Market-Ready Honey

- Why must commercial honey storage have high-precision temperature control? Protect Bioactivity and Product Value

- Why is temperature-controlled industrial equipment required for processing honey bee feeding syrup? Ensure Hive Safety

- How does a honey super warmer facilitate the honey filtering and bottling process? Boost Your Extraction Efficiency

- Why is the use of precision temperature-controlled heating equipment necessary? Protect Your Bees from HMF Toxicity

- What thermostat options are available for honey heating blankets? Find the Perfect Heat Control for Your Harvest

- What is the function of pre-heated water baths in honey processing? Optimize Liquefaction and Filtration Efficiency