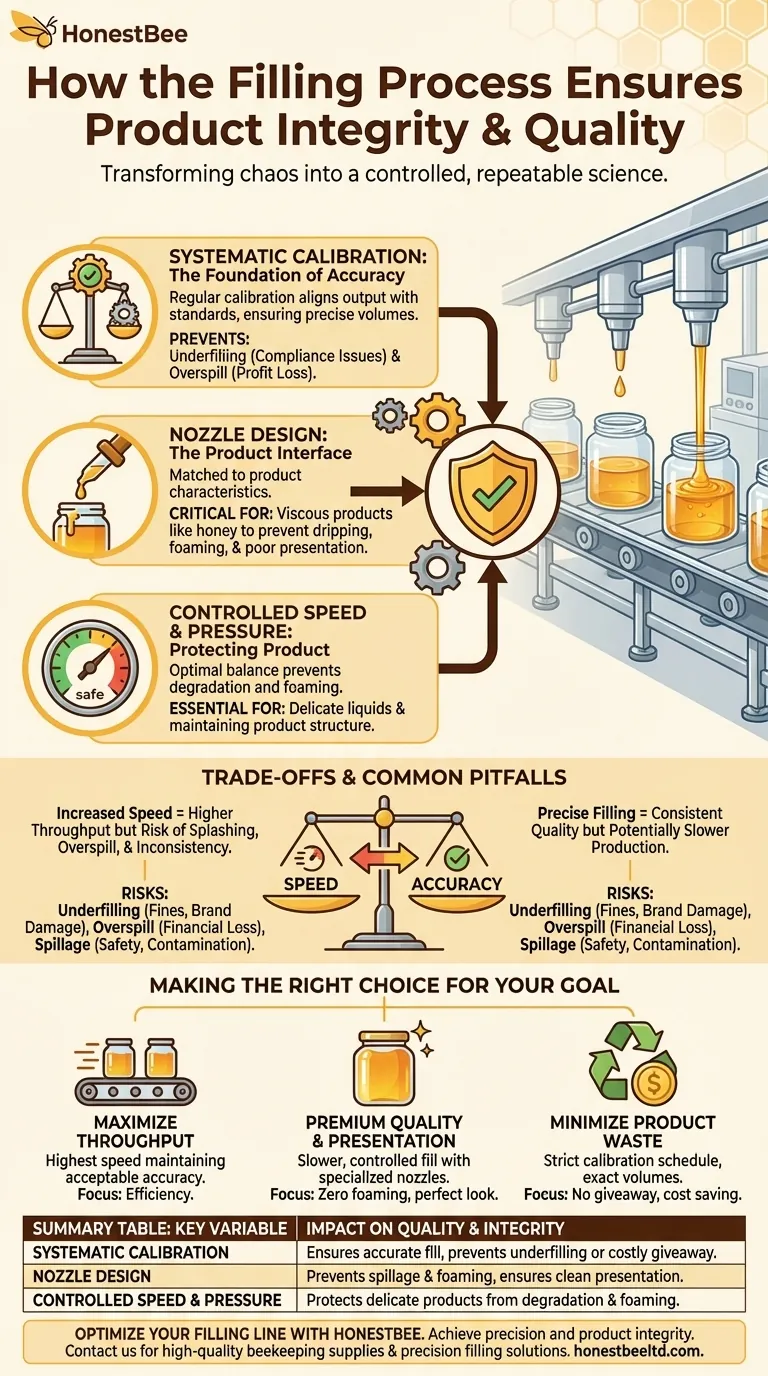

At its core, the filling process ensures product integrity and quality by transforming a potentially chaotic procedure into a highly controlled, repeatable science. This is achieved through the precise management of the filling machinery’s mechanical settings, including regular calibration, the use of appropriate nozzles, and fine-tuned control over filling speed and pressure. These adjustments work in concert to guarantee that every container is filled accurately and without damaging the product.

The ultimate goal of a quality filling process is not merely to dispense a product, but to do so with unwavering precision. True product integrity is achieved when quality is engineered into the mechanics of the process itself, rather than being inspected for after the fact.

The Core Pillars of Filling Quality

To maintain product integrity, you must master several key variables in the filling process. Each plays a distinct role in delivering a consistent and high-quality final product.

Systematic Calibration: The Foundation of Accuracy

Calibration is the process of aligning the filling machine’s output with a known standard, ensuring the volume it dispenses is precisely what you intend. This is the bedrock of consistency.

Without regular calibration, machines can "drift," leading to gradual inaccuracies. This results in underfilled containers, which can cause regulatory issues and customer dissatisfaction, or overfilled containers, which waste product and reduce profitability.

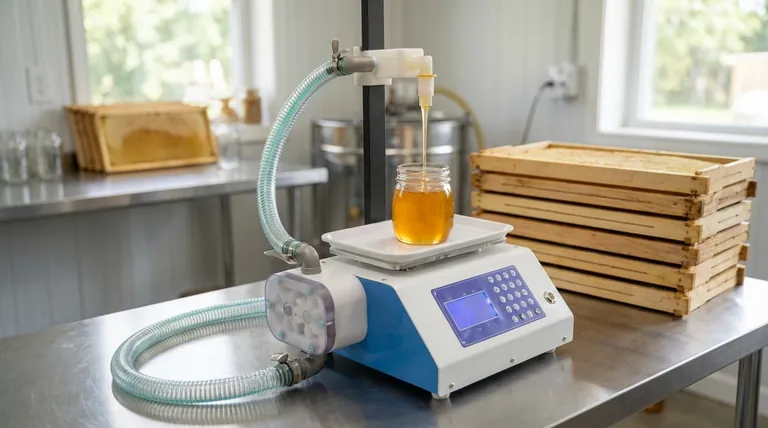

Nozzle Design: The Interface with Your Product

The nozzle is the final point of contact between the machine and your product. Its design is critical and must be matched to the product's characteristics and the container opening.

For example, a viscous product like honey requires a different nozzle than a thin, watery liquid to prevent dripping or splashing. Using the wrong nozzle can lead to spillage, foaming, or an unsightly final presentation, directly impacting perceived quality.

Controlled Speed and Pressure: Protecting Product Integrity

The speed and pressure at which a product is filled directly affect its physical state. Aggressive, high-speed filling can be efficient, but it can also degrade the product.

Delicate liquids or products prone to foaming, such as carbonated drinks or certain soaps, require a slower, more controlled fill. Finding the optimal balance between speed and control is essential for maintaining the product's intended structure and appearance.

Understanding the Trade-offs and Common Pitfalls

Optimizing a filling line involves balancing competing priorities. Understanding these trade-offs is key to avoiding common mistakes that undermine quality.

The Conflict: Speed vs. Accuracy

The most fundamental trade-off is between production speed and filling accuracy. Pushing for maximum throughput by increasing fill speed often comes at the cost of precision.

Faster speeds can increase the momentum of the liquid, leading to splashing and overspill. This makes it harder for the machine's sensors or timers to achieve a precise cut-off, resulting in inconsistent fill levels.

The Risk: Underfilling and Overspill

Underfilling is a serious compliance issue. Weights and measures regulations are strict, and failing to deliver the advertised amount of product can lead to fines and brand damage.

Overspill or "product giveaway" is a direct hit to your bottom line. Consistently giving away even a small percentage of extra product in every container accumulates into significant financial loss over time.

The Hazard: Spillage and Contamination

Spillage is not just a form of product waste; it is an operational hazard. Spilled product on machinery or floors can create safety risks and requires additional labor to clean.

More importantly, it creates a vector for contamination. If not managed properly, spillage can compromise the sterile environment of the production line, jeopardizing the integrity of subsequent batches.

Making the Right Choice for Your Goal

Your operational strategy should dictate how you tune your filling process. By prioritizing a specific goal, you can configure your system for optimal performance.

- If your primary focus is maximizing throughput: Find the highest fill speed that maintains an acceptable level of accuracy and prevents significant spillage.

- If your primary focus is premium quality and presentation: Prioritize a slower, controlled fill with specialized nozzles designed to eliminate foaming and splashing entirely.

- If your primary focus is minimizing product waste: Implement a strict and frequent calibration schedule to ensure fill volumes are exact, eliminating costly product giveaway.

Mastering these variables gives you direct control over the quality and integrity of your final product.

Summary Table:

| Key Variable | Impact on Quality & Integrity |

|---|---|

| Systematic Calibration | Ensures accurate fill volumes, preventing underfilling or costly product giveaway. |

| Nozzle Design | Matched to product viscosity to prevent spillage, foaming, and ensure a clean presentation. |

| Controlled Speed & Pressure | Protects delicate products from degradation, foaming, or splashing, maintaining structure. |

Optimize Your Filling Line for Uncompromising Quality

Are you a commercial apiary or beekeeping equipment distributor struggling with inconsistent fills, product waste, or presentation issues? The precision of your filling process directly impacts your bottom line and brand reputation.

HONESTBEE supplies the high-quality beekeeping supplies and equipment you need to engineer quality into your operations. From durable, precision-calibrated filling machines to nozzles designed for viscous products like honey, we help you achieve the perfect balance of speed, accuracy, and product integrity.

Contact us today to discuss how our wholesale-focused solutions can enhance your filling process and protect your product's quality.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- What are the different principles used in honey filling machines? Choose the Right Method for Your Apiary

- What is the value of industrial hive-making and honey-filling equipment for beekeeping? Scale Your Apiary Business

- How do automated filling machines contribute to honey production? Scale Your Apiary with Precision Packaging

- What are the primary advantages of using automated bee product filling machines? Boost Your Honey Processing Efficiency

- How can honey flow and weight consistency be optimized? Master Bottling with Temperature and Precision Control

- How do hive-making machinery and honey-filling machines contribute to commercial apiaries? Drive Scale and Efficiency

- What causes film jamming in a honey stick machine and how can it be resolved? 3 Pro Fixes for Seamless Production

- How does high-precision filling equipment ensure quality and efficiency? Optimize Your Honey Packaging Performance