To reduce the moisture level in honey, you must expose it to dry air to facilitate evaporation. The most common methods involve using a dehumidifier and fans in a sealed room to circulate dry air over the honey's surface, gently heating the honey to speed up evaporation, or using specialized commercial equipment like vacuum dryers or rotating disc systems. Regardless of the method, success depends on maximizing the honey's surface area and accurately measuring the moisture content with a refractometer.

The core challenge in reducing honey moisture is not just removing water, but doing so without damaging the honey's delicate enzymes and flavor profile. The safest and most effective methods prioritize controlled airflow over high heat.

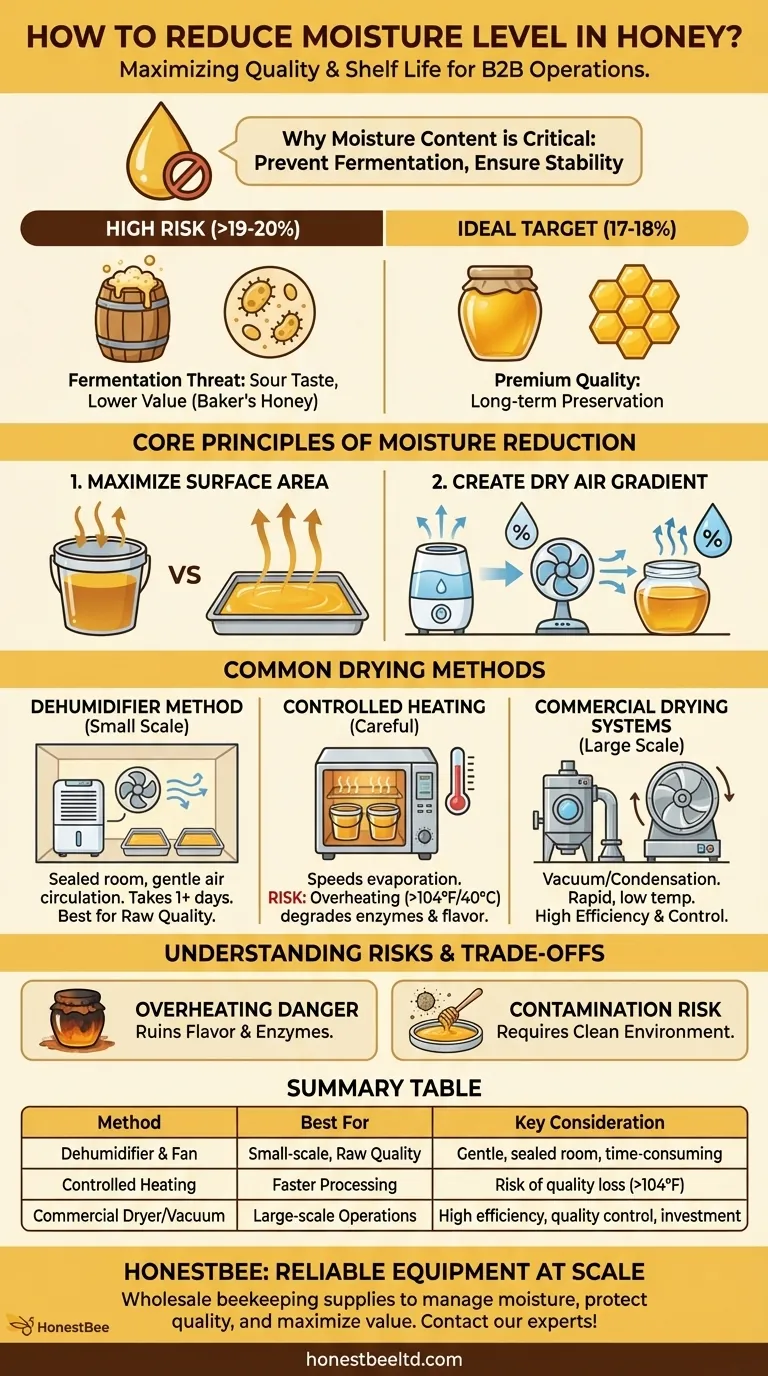

Why Moisture Content is Critical

The moisture content of honey is the single most important factor determining its shelf life and quality. Uncapped honey in the hive has not yet been sufficiently dehydrated by the bees.

The Threat of Fermentation

Honey with a moisture content above 19-20% is at high risk of fermentation. Wild yeasts naturally present in honey can become active in this excess water, converting the sugars into alcohol and carbon dioxide.

This process spoils the honey, giving it a sour, "off" taste. Fermented honey can no longer be sold as high-quality table honey and is often relegated to lower-value "baker's honey."

The Ideal Moisture Target

For long-term stability and premium quality, the ideal moisture content for honey is between 17% and 18%. This level is low enough to prevent fermentation entirely, ensuring the honey remains preserved indefinitely.

Core Principles of Moisture Reduction

All effective methods for drying honey rely on two fundamental scientific principles working together. Understanding them allows you to create the right conditions, even with simple equipment.

Principle 1: Maximizing Surface Area

Water can only evaporate from the surface of the honey. A deep bucket of honey has a very small surface area relative to its volume, making natural evaporation incredibly slow.

To speed up the process, you must increase the surface area. This can be done by spreading the honey in shallow trays or by using commercial systems with rotating discs that continuously coat themselves in a thin film of honey.

Principle 2: Creating a Dry Air Gradient

Evaporation occurs when the air directly above the honey is drier than the honey itself. The bigger the difference in humidity, the faster the water will move from the honey into the air.

This is why simply letting honey sit out in a humid climate is ineffective. You must actively create a low-humidity environment using a dehumidifier or a sealed drying system. Circulating this dry air with a fan constantly replaces the now-moist air at the honey's surface, maintaining a steep drying gradient.

Common Methods for Drying Honey

Methods range from simple DIY setups for hobbyists to sophisticated machinery for commercial operations.

The Dehumidifier Method (Small Scale)

This is the most common and safest method for small-scale beekeepers. It involves creating a small, sealed "drying room," which can be a closet or a small dedicated room.

Place the honey in shallow, food-safe trays to maximize surface area. Run a dehumidifier in the room to pull moisture from the air, and use a small fan to gently circulate the resulting dry air over the honey. This process can take one to several days.

Controlled Heating

Heating reduces honey's viscosity (making it thinner) and speeds up evaporation. This can be done with specialized bucket heaters or in a warming cabinet.

However, this method requires extreme care. Heating honey above 104°F (40°C) can begin to destroy its beneficial enzymes and delicate aromatic compounds, compromising its quality as a raw product.

Commercial Drying Systems

Large-scale producers use specialized equipment for efficiency and control.

A honey dryer often works on a condensation principle. It heats air, passes it over the honey to collect moisture, then cools the moist air on an evaporator coil to condense the water out. The now-dry air is reheated and recirculated.

Vacuum systems pull a vacuum over the honey, which lowers the boiling point of water. This allows for rapid moisture removal at very low temperatures, preserving the honey's quality.

Understanding the Trade-offs and Risks

While reducing moisture is necessary, improper techniques can do more harm than good.

The Danger of Overheating

Heat is the fastest way to remove water, but it's also the fastest way to ruin honey. Overheating degrades the flavor, darkens the color, and destroys the enzymes that make raw honey valuable. Gentle, low-temperature methods are always superior for quality.

The Need for Accurate Measurement

You cannot manage what you do not measure. Guessing the moisture content is a recipe for failure. A honey refractometer is an essential, non-negotiable tool. You must measure the moisture level before, during, and after the process to know when you have reached your target.

Risk of Contamination

Any time you expose honey to air, you risk introducing dust, lint, or other contaminants. Ensure your drying area is exceptionally clean. Using food-grade containers and covering them with a fine screen can help protect the product.

Making the Right Choice for Your Goal

Your choice of method depends entirely on your scale of operation and your quality goals.

- If your primary focus is preserving raw honey quality on a small scale: The sealed room with a dehumidifier and fan is your best option. It is gentle, low-cost, and highly effective.

- If your primary focus is processing speed for a mid-to-large operation: Investing in a dedicated commercial honey dryer or vacuum system provides the control and efficiency needed to handle large volumes reliably.

- If your primary focus is simply avoiding fermentation with minimal equipment: Spreading honey in shallow trays in a very dry, warm, and clean indoor space with a fan can work, but it requires constant monitoring with a refractometer.

Ultimately, protecting the value of your honey means taking control of its moisture content before storage.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Dehumidifier & Fan | Small-scale beekeepers, raw honey quality | Gentle, requires a sealed room, takes 1+ days |

| Controlled Heating | Faster processing | Risk of quality loss if heated above 104°F (40°C) |

| Commercial Dryer/Vacuum System | Large-scale operations | High efficiency and quality control, higher investment |

Need reliable equipment to control honey moisture at scale? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-focused beekeeping supplies. Our durable equipment helps you efficiently manage moisture levels, protect your honey's quality, and maximize your product's value. Contact our experts today to find the right solution for your operation!

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What principle does the honey vacuum thickener use to concentrate honey? Preserve Quality with Low-Temperature Evaporation

- What was the process for drying lumber for beehive supers? Achieve 8-9% Moisture for Precision Joint Stability

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- Why is industrial-grade dehumidification equipment essential for producing commercial-standard honey? Expert Insights