Beyond measuring the moisture in honey, the refractometer is an essential tool across the food and beverage industry, in scientific and industrial laboratories, and even for culinary hobbyists. Its versatility comes from a single, fundamental principle: its ability to measure the concentration of a substance dissolved in a liquid simply by measuring how light bends as it passes through a sample.

The true value of a refractometer is not tied to any single product but to its universal function. It provides a simple, instant way to measure the concentration of dissolved solids, making it a powerful tool for quality control and consistency in countless applications.

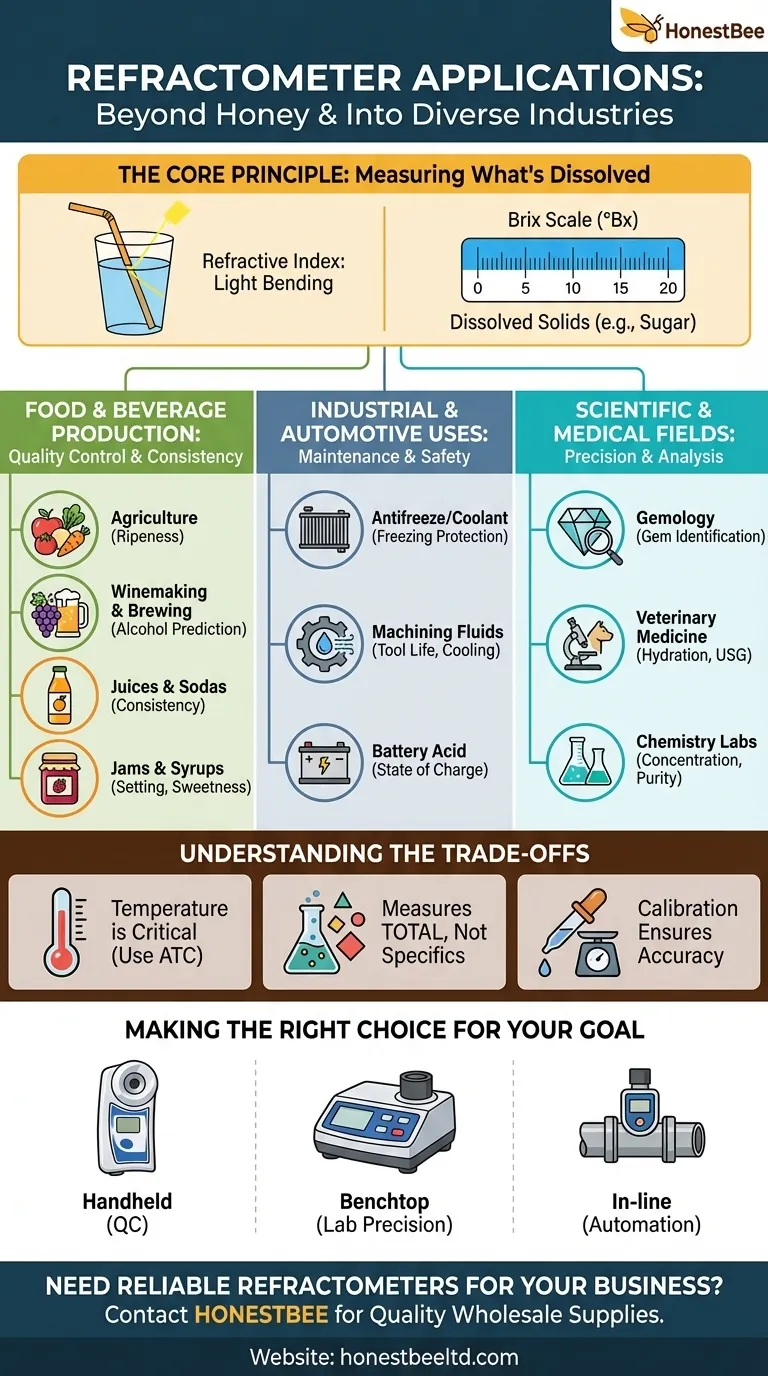

The Core Principle: Measuring What's Dissolved

A refractometer's power lies in its simplicity. It measures a physical property called the refractive index, which is a number that describes how much a beam of light bends when it enters a liquid.

How Refractive Index Works

When you place a straw in a glass of water, it appears "broken" at the water's surface. This illusion is caused by light refraction.

A refractometer precisely measures this bending effect. The more solids (like sugar, salt, or proteins) dissolved in a liquid, the denser it becomes, and the more it will bend light.

The Brix Scale: A Universal Language

For many applications, this measurement is translated into the Brix (°Bx) scale. One degree Brix is equal to 1 gram of sucrose (sugar) in 100 grams of solution.

While technically a measure of sugar, the Brix scale is widely used as a proxy for the total concentration of dissolved solids in a sample, making it a quick indicator of quality or consistency.

Key Applications Across Industries

Understanding the principle of measuring dissolved solids reveals why the refractometer is so widely adopted. Its application is limited only by the need to measure the concentration of a liquid solution.

Food and Beverage Production

This is the most common field for refractometers. They are used for quality control at every stage, from raw ingredients to the final product.

- Agriculture: Farmers measure the Brix of fruits and vegetables to determine peak ripeness and harvest time. Higher Brix often correlates with better flavor and nutritional content.

- Winemaking & Brewing: Vintners and brewers measure the sugar content of grape juice (must) and wort to predict the final alcohol content of wine and beer.

- Juices & Sodas: Manufacturers ensure product consistency by verifying the sugar concentration meets brand standards.

- Jams, Jellies & Syrups: The Brix value is critical for ensuring proper setting, sweetness, and shelf stability.

Industrial and Automotive Uses

Beyond food, refractometers are crucial for maintaining industrial machinery and vehicle safety.

- Antifreeze/Coolant: Mechanics use them to check the concentration of ethylene or propylene glycol in engine coolant, ensuring it provides adequate protection against freezing and boiling.

- Machining Fluids: The concentration of water-soluble cutting and grinding fluids is monitored to optimize tool life, cooling performance, and corrosion resistance.

- Battery Acid: Technicians can check the specific gravity of battery acid to assess a lead-acid battery's state of charge.

Scientific and Medical Fields

In laboratory settings, precision is key, and refractometers provide rapid, reliable data.

- Gemology: Gemologists use specialized refractometers to identify gemstones, as each mineral has a unique and well-documented refractive index.

- Veterinary Medicine: Vets can quickly assess animal hydration and kidney function by measuring urine specific gravity (USG) or check blood protein levels.

- Chemistry Labs: Researchers use them to determine the concentration of a known solute in a solution or to identify the purity of a compound.

Understanding the Trade-offs

While incredibly useful, a refractometer is not an all-knowing device. It is important to be aware of its limitations to ensure you are interpreting its readings correctly.

Temperature is a Critical Factor

The refractive index of a liquid changes with temperature. Most modern handheld refractometers have Automatic Temperature Compensation (ATC) to correct for this, but it's essential to know if your device has this feature and to operate within its specified temperature range.

It Measures a Total, Not Specifics

A standard refractometer reads the total concentration of all dissolved solids. It cannot distinguish between different types of sugars (like fructose and sucrose) or tell you if other substances, like salts or acids, are contributing to the reading.

Calibration Ensures Accuracy

For reliable results, a refractometer must be calibrated regularly. This is typically a simple process done with a few drops of distilled water, which should read as zero on the Brix scale.

Making the Right Choice for Your Goal

The right refractometer depends entirely on your specific application and the level of precision you require.

- If your primary focus is food, brewing, or automotive maintenance: A simple handheld analog or digital refractometer with ATC is an affordable and perfectly sufficient tool for these quality control checks.

- If your primary focus is high-precision lab work or gemology: An Abbe or benchtop refractometer is necessary for the enhanced accuracy, temperature control, and precision these fields demand.

- If your primary focus is industrial process automation: In-line process refractometers are integrated directly into piping to provide continuous, real-time monitoring and feedback for automated systems.

Ultimately, understanding the core principle of light refraction empowers you to see the refractometer not as a single-purpose tool, but as a versatile key to unlocking data on liquid concentration in nearly any field.

Summary Table:

| Industry | Primary Use | Key Measurement |

|---|---|---|

| Food & Beverage | Quality control, ripeness, alcohol prediction | Brix (°Bx) for sugar/solids concentration |

| Industrial/Automotive | Coolant strength, machining fluid concentration | Glycol percentage, fluid concentration |

| Scientific/Medical | Gemstone ID, urine specific gravity, protein levels | Refractive Index, Specific Gravity |

Need Reliable Refractometers for Your Business?

Whether you are a commercial apiary, a beekeeping equipment distributor, or operate in food production or industrial maintenance, precise tools are essential for quality control. HONESTBEE supplies durable, accurate refractometers and other essential beekeeping supplies and equipment through our wholesale-focused operations.

Contact HONESTBEE today to discuss your equipment needs and discover how we can support your operations with quality wholesale supplies.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability