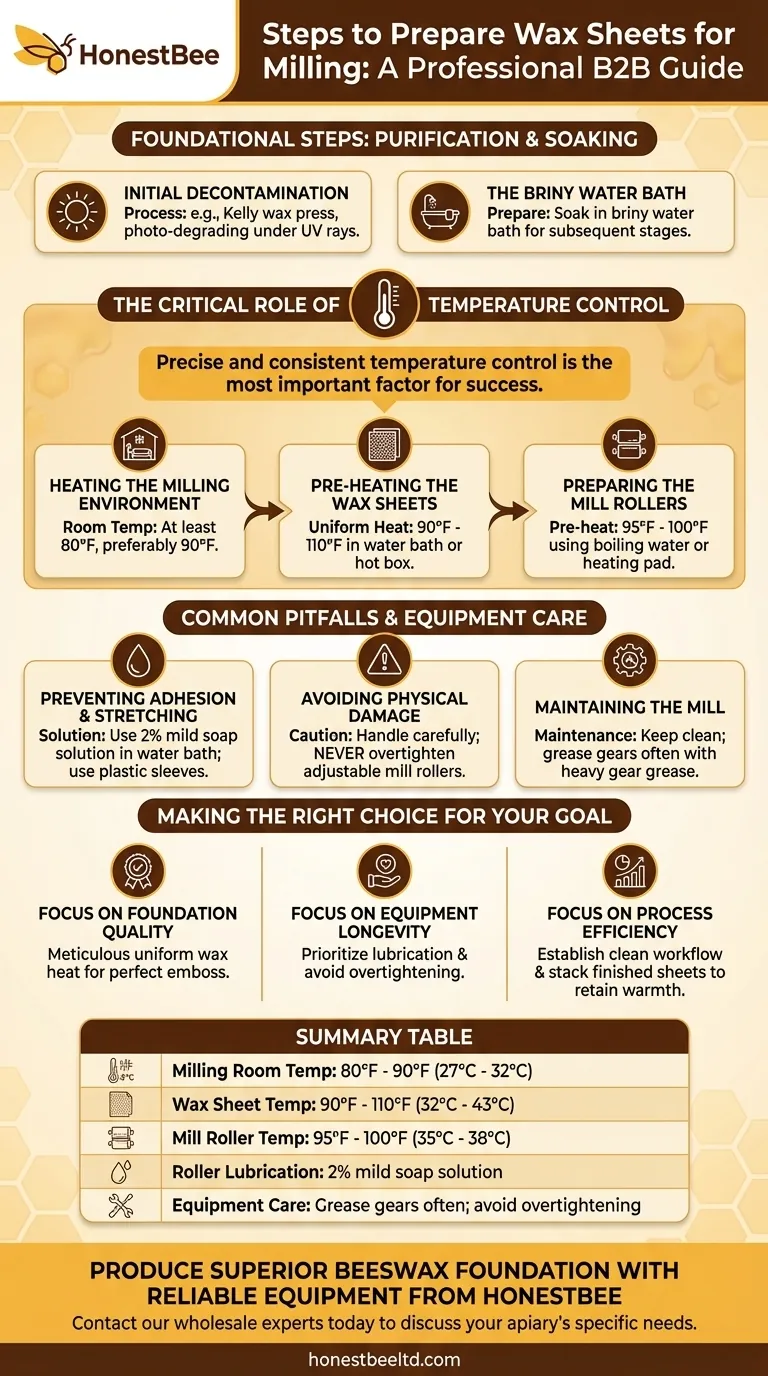

Preparing wax sheets for milling is a meticulous process that begins long before the wax touches the rollers. The essential steps involve decontamination and soaking, followed by the critical stage of uniformly heating the wax, the milling room, and the mill rollers to specific temperature ranges to ensure the wax is pliable and produces a high-quality foundation.

The success of milling beeswax foundation hinges on one central principle: precise and consistent temperature control. Failure to properly heat the wax, the environment, and the equipment will lead to sticking, tearing, and damage to both the foundation and the mill itself.

Foundational Steps: Purification and Soaking

The initial preparation of the wax is designed to purify it and ready it for the physical stress of milling.

Initial Decontamination

Before milling, wax sheets are often decontaminated. This can involve processes like using a Kelly wax press and photo-degrading the sheets under the UV rays of the sun.

The Briny Water Bath

Following decontamination, the wax sheets are soaked in a briny water bath. This step prepares the wax for the subsequent heating and milling stages.

The Critical Role of Temperature Control

Achieving the correct temperature for every component of the milling process is the most important factor for success. This ensures the wax flows correctly without becoming brittle or overly sticky.

Heating the Milling Environment

The room itself must be heated to at least 80°F, with 90°F being preferable. This warm environment prevents the pre-heated wax sheets from cooling down too quickly during handling.

Pre-heating the Wax Sheets

The wax sheets must be heated uniformly to a temperature between 90°F and 110°F. This can be accomplished in a thermostat-controlled water bath or a dedicated hot box, ensuring the entire sheet is pliable.

Preparing the Mill Rollers

The mill rollers must also be pre-heated to approximately 95°F - 100°F. This can be done by carefully using boiling water or a heating pad, preventing the cold metal from shocking and hardening the wax on contact.

Common Pitfalls and Equipment Care

Proper technique and maintenance are essential for producing a quality product and protecting your investment in the milling equipment.

Preventing Adhesion and Stretching

To prevent the warm wax from sticking to the rollers, use a water bath containing a 2% solution of mild, biodegradable soap. This solution seasons the rollers. It's also wise to place wax sheets in a plastic sleeve during handling to prevent stretching and distortion of the cell size.

Avoiding Physical Damage

During the milling process, you must handle the foundation carefully to avoid stretching it. On an adjustable mill, never screw the rollers down too tightly, as this can cause permanent damage to the delicate embossing heads.

Maintaining the Mill

Keep the milling area exceptionally clean to prevent debris from embedding in the wax sheets. The mill's gears should be greased often with a heavy gear grease to ensure they run tight and to reduce operational wear.

Making the Right Choice for Your Goal

Your specific objective will determine which steps require the most attention.

- If your primary focus is foundation quality: Pay meticulous attention to achieving uniform heat in the wax sheets, as this ensures a perfect emboss without weak spots.

- If your primary focus is equipment longevity: Prioritize proper lubrication of the gears and avoid overtightening the rollers to prevent costly damage.

- If your primary focus is process efficiency: Establish a clean workflow and stack finished sheets neatly between paper to retain warmth, which improves their ductility for easier handling later.

By mastering these preparatory steps, you transform a simple sheet of wax into a perfect foundation for a thriving honey bee colony.

Summary Table:

| Key Preparation Step | Critical Details |

|---|---|

| Milling Room Temperature | Heat to 80°F - 90°F (27°C - 32°C) |

| Wax Sheet Temperature | Pre-heat uniformly to 90°F - 110°F (32°C - 43°C) |

| Mill Roller Temperature | Pre-heat to 95°F - 100°F (35°C - 38°C) |

| Roller Lubrication | Use a 2% mild soap solution in the water bath |

| Equipment Care | Grease gears often; avoid overtightening rollers |

Produce Superior Beeswax Foundation with Reliable Equipment from HONESTBEE

Mastering the milling process requires not just skill but also dependable, high-quality equipment. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, precision tools needed for efficient, large-scale foundation production.

Let us help you optimize your output and protect your investment. Contact our wholesale experts today to discuss your apiary's specific needs.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency