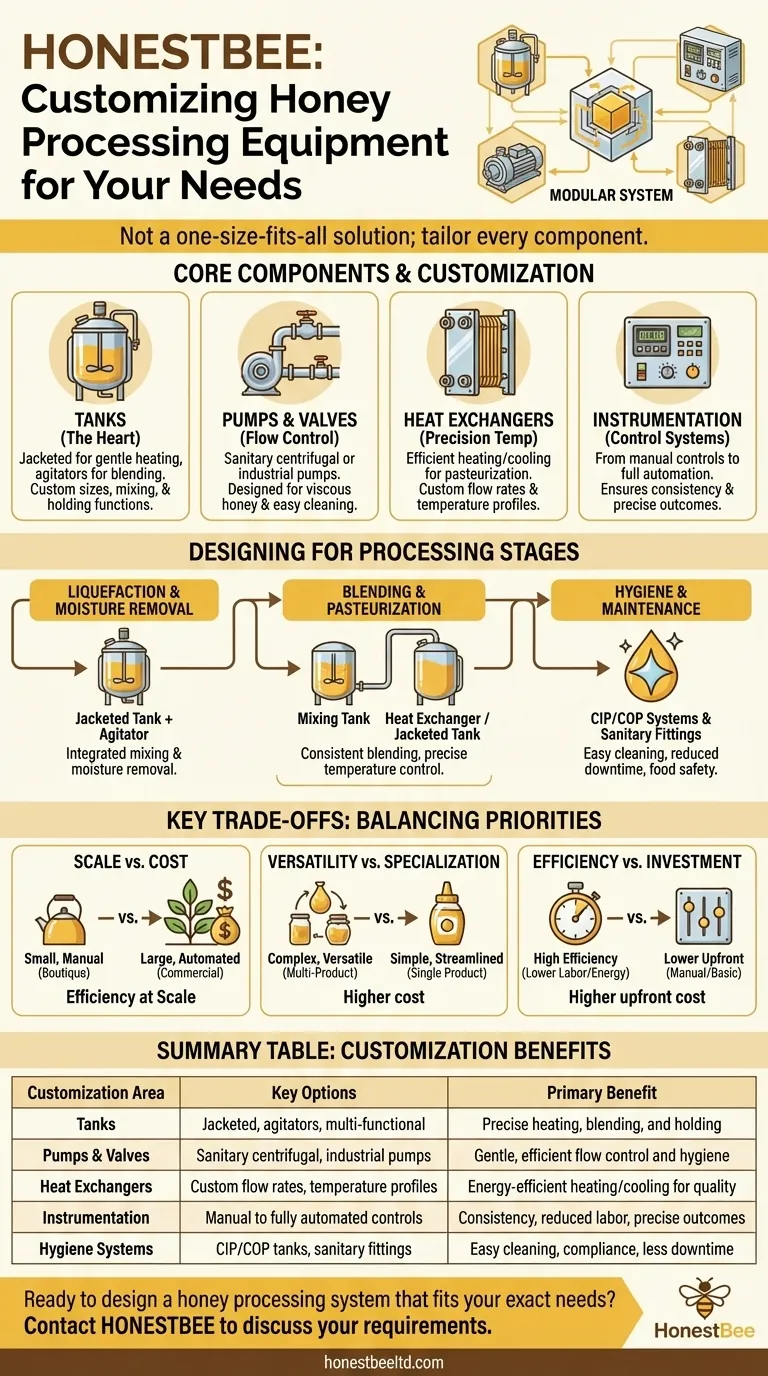

To put it simply, honey processing equipment is not a one-size-fits-all solution; it is a modular system where nearly every component can be tailored to your specific needs. Key customizable elements include the size and type of tanks (for mixing, heating, and cleaning), pumps, valves, fittings, and the level of instrumentation used to control the process. This customization ensures the final system perfectly matches your operational scale and product goals.

The central goal of customization is not just to add features, but to design a fully integrated system. The right configuration will align with your production volume, desired honey characteristics, and budget to maximize efficiency, quality, and hygiene.

Core Components and Their Customization

Understanding which components can be customized is the first step in designing a system that works for you. Each part plays a critical role in the final quality of your honey.

Tanks: The Heart of the Operation

Tanks are the most fundamental component in honey processing. Customization here focuses on their specific function, such as liquefying, blending, or holding.

Jacketed tanks, which allow for hot water circulation, are essential for gently heating honey to dissolve crystals or for pasteurization. The inclusion of a central stirrer or agitator can be specified to ensure even heating and blending of different honey varieties.

Pumps, Valves, and Fittings: Controlling the Flow

Honey is a viscous product, and moving it efficiently and gently is paramount. The choice of pumps—often sanitary centrifugal or industrial pumps—is a key customization point.

The entire system of pipes, valves, and sanitary fittings must be designed to not only handle the product but also to allow for easy and thorough cleaning. This is crucial for preventing contamination and maintaining product integrity.

Heat Exchangers: Precision Temperature Control

For larger operations, heat exchangers offer a more efficient method of heating and cooling honey compared to jacketed tanks alone.

These can be customized for a specific flow rate and temperature profile, which is critical for controlled pasteurization and for cooling the honey quickly to prevent unwanted darkening or degradation of its delicate flavors.

Instrumentation and Control Systems

The level of automation is a significant area for customization. A basic setup may rely on manual controls and thermometers.

A more advanced, customized system will include integrated instrumentation to automatically control temperatures, mixing times, and pump speeds. This ensures consistency, reduces labor, and provides precise control over the final product characteristics.

Designing for Key Processing Stages

Custom equipment choices directly impact the efficiency and outcome of each step in your process. The system should be viewed as a whole, designed to achieve specific outcomes from start to finish.

For Liquefaction and Moisture Removal

To process crystallized honey or reduce its moisture content, a jacketed tank with an agitator is the primary tool. An integrated system can be designed to perform both mixing and moisture removal in a single, efficient plant, saving time and energy.

For Blending and Pasteurization

Creating a consistent blend from different honey sources requires a mixing tank with an appropriate stirrer. For pasteurization, the system must be able to heat the honey to a specific temperature and hold it for a set duration, demanding precise control from either a jacketed tank or a heat exchanger.

For Hygiene and Maintenance

An operation's cleaning protocol heavily influences equipment design. Systems can be customized with Clean-In-Place (CIP) or Clean-Out-of-Place (COP) tanks and sanitary fittings. This hygienic design simplifies cleaning, reduces downtime, and is essential for meeting food safety standards.

Understanding the Key Trade-offs

Choosing the right level of customization requires balancing competing priorities. Being aware of these trade-offs is crucial for making a sound investment.

Scale vs. Cost

A small, boutique operation has vastly different needs than a large commercial plant. While a fully automated system with dedicated CIP tanks offers maximum efficiency, its cost is only justifiable at a larger scale. Smaller producers may opt for more manual, multi-purpose equipment like a single jacketed kettle.

Product Versatility vs. Specialization

A system designed exclusively for producing liquid clover honey will be simpler and more streamlined than one intended to also produce creamed honey, infused honey, or other value-added products. Versatility often requires more complex mixing tanks and more precise temperature controls, which can increase initial costs.

Efficiency vs. Upfront Investment

Investing in components like heat exchangers and automated instrumentation significantly increases upfront costs. However, these customizations pay for themselves over time through reduced energy consumption, lower labor requirements, and greater product consistency, which are key advantages for high-volume producers.

Making the Right Choice for Your Operation

Ultimately, the ideal equipment configuration depends entirely on your operational goals.

- If your primary focus is small-scale, artisanal production: Prioritize versatile, multi-function equipment like a high-quality jacketed mixing tank that gives you precise manual control over your batches.

- If your primary focus is large-scale commercial processing: Invest in an integrated, automated system with dedicated CIP capabilities and efficient heat exchangers to maximize throughput, consistency, and hygiene.

- If your primary focus is creating value-added products (e.g., creamed or infused honey): Ensure your system includes specialized mixing equipment and precise temperature controls for both heating and cooling to manage crystallization and ingredient blending.

Tailoring your equipment to your process is the most critical step in building an efficient and successful honey operation.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Tanks | Jacketed, with agitators, multi-functional | Precise heating, blending, and holding |

| Pumps & Valves | Sanitary centrifugal, industrial pumps | Gentle, efficient flow control and hygiene |

| Heat Exchangers | Custom flow rates, temperature profiles | Energy-efficient heating/cooling for quality |

| Instrumentation | Manual to fully automated controls | Consistency, reduced labor, precise outcomes |

| Hygiene Systems | CIP/COP tanks, sanitary fittings | Easy cleaning, compliance, less downtime |

Ready to design a honey processing system that fits your exact needs? At HONESTBEE, we specialize in supplying customizable beekeeping supplies and equipment to commercial apiaries and distributors. Whether you're scaling up production or developing value-added products, our tailored solutions ensure maximum efficiency, hygiene, and honey quality. Contact us today to discuss your requirements and get a system designed for your success!

Visual Guide

Related Products

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- How is the honey press cleaned and maintained? Essential Tips for Longevity and Hygiene

- What happens to the wax after pressing in a honey press? A Guide to Maximizing Your Hive's Yield

- What are the benefits of the screw design in a stainless steel honey pump? Preserve Honey Quality and Integrity

- How do honey processing machinery and pollination services create commercial synergy? Boost Apiary Revenue Efficiency

- How do you press honey out of a comb? A Simple Guide to the Crush and Strain Method