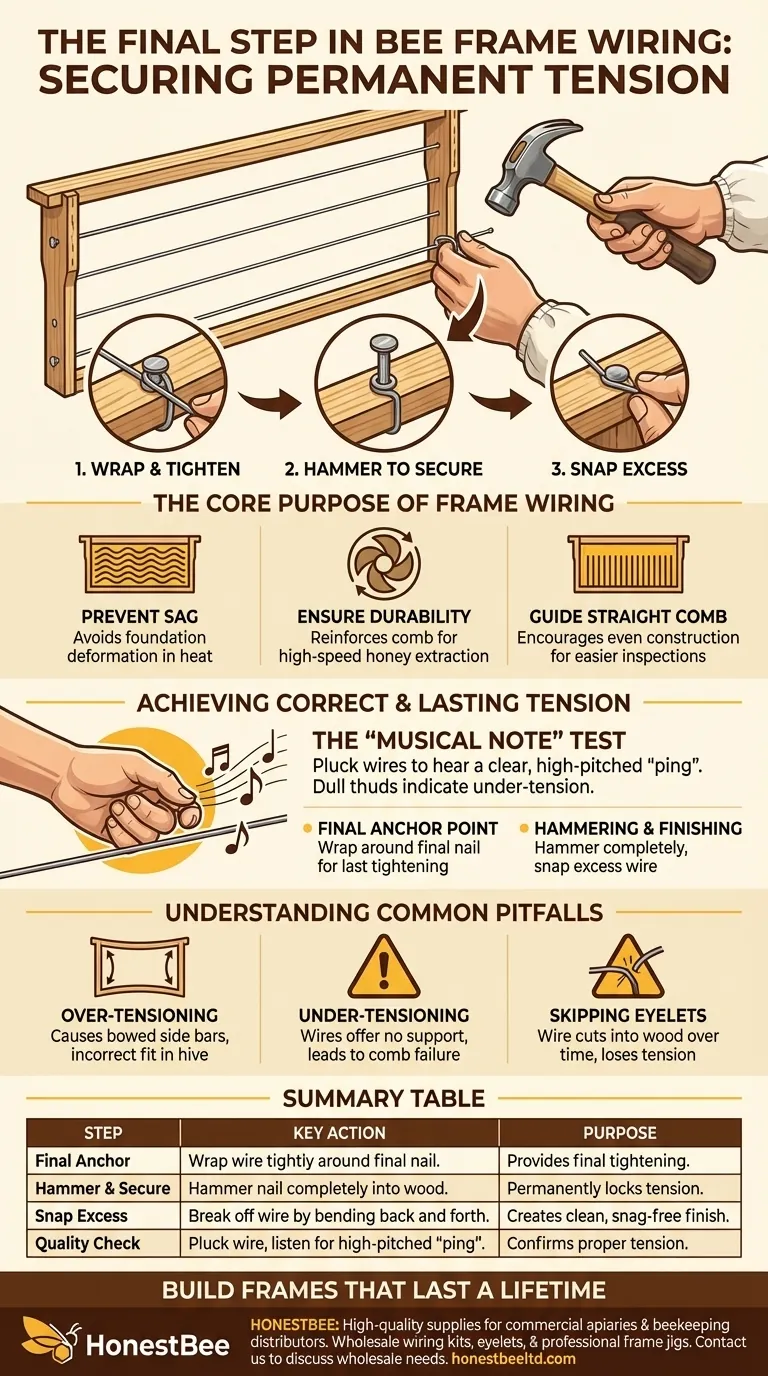

The final step in wiring a bee frame is to secure the wire's tension permanently. This is accomplished by hammering down the final nail you've wrapped the wire around, then breaking off the excess wire by bending it back and forth until it snaps flush against the nail head.

The mechanical act of hammering a nail is the last step, but the true final measure of success is achieving proper wire tension. This tension, often tested by listening for a musical "ping," is what ensures the frame can support the foundation and withstand the forces of honey extraction.

The Core Purpose of Frame Wiring

Wiring provides the crucial internal skeleton for the beeswax foundation that bees build their comb upon. Without it, the entire structure is prone to failure.

Preventing Foundation Sag

Beeswax is a soft material. Inside a hot hive, an unsupported sheet of wax foundation will sag, warp, and deform under its own weight, leading to improperly drawn and often unusable comb.

Ensuring Durability During Extraction

The primary function of wiring is to reinforce the comb for honey extraction. During this process, frames are spun at high speed, exerting significant centrifugal force. Wires prevent the heavy, honey-filled comb from blowing out and being destroyed.

Guiding Straight Comb Construction

The taut wires act as a guide, encouraging the bees to build straight, even comb within the confines of the frame. This makes inspections and management far easier.

Achieving Correct and Lasting Tension

The quality of a wired frame is defined by its tension. This is the skill that separates a functional frame from a future problem.

The "Musical Note" Test

The most reliable, time-tested method for checking tension is to pluck the wires like a guitar string. A properly tensioned wire will produce a clear, high-pitched "ping" or musical note. A dull thud indicates the wire is too loose.

The Final Anchor Point

Once you have worked the wire through the eyelets and achieved the desired musical tension, wrap it tightly around the final, partially driven nail. Pulling the wire against the nail head provides the final tightening before you secure it.

Hammering and Finishing

With tension held, hammer the nail in completely, trapping the wire securely between the nail and the wood frame. The excess wire can then be snapped off by sharply wiggling it back and forth. This creates a clean break with no sharp points to snag on later.

Understanding the Common Pitfalls

Wiring a frame is a balance. Both over-tightening and under-tightening create distinct problems that undermine your efforts.

The Danger of Over-Tensioning

Applying too much force when tightening the wires is a common mistake. Excessive tension will physically bow the vertical side bars of the frame inward. A bowed frame will not fit correctly alongside other frames in the hive body, creating incorrect spacing and management headaches.

The Inevitable Failure of Under-Tensioning

Loose wires offer no meaningful support. Foundation will still sag in the heat, and the comb will almost certainly be destroyed during honey extraction. If your wires don't "sing" when plucked, they are too loose to do their job.

The Shortcut of Skipping Eyelets

Some beekeepers skip installing metal eyelets where the wire enters and exits the frame holes. This is a mistake. The wire's high tension will slowly cut into the soft wood over time, causing the wire to lose all tension and rendering it useless. Eyelets are a small step that ensures the frame's long-term integrity.

Making the Right Choice for Your Goal

After snapping off the final wire, your frame is ready for foundation. The quality of your work at this stage directly impacts the hive's future.

- If your primary focus is maximum durability: Strive for that high-pitched, musical "ping" on every wire and never skip using eyelets.

- If your primary focus is efficient assembly: Use a dedicated wiring jig or board to hold the frame rigid, which makes achieving consistent tension much faster.

- If you are troubleshooting a bad frame: Look for bowed sidebars (a sign of past over-tensioning) or wires that feel slack and don't make a sound when plucked.

A properly wired frame is the literal foundation of a strong, productive, and easily managed beehive.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| Final Anchor | Wrap wire tightly around the final nail. | Provides the final tightening before permanent securing. |

| Hammer & Secure | Hammer the nail completely into the wood. | Permanently locks the wire tension in place. |

| Snap Excess | Break off excess wire by bending it back and forth. | Creates a clean, snag-free finish. |

| Quality Check | Pluck the wire and listen for a clear, high-pitched 'ping'. | Confirms proper tension for comb support and extraction durability. |

Build Frames That Last a Lifetime

A perfectly wired frame is the backbone of a productive hive. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality supplies needed for this precise work.

From durable wiring kits and eyelets to professional-grade frame jigs, our wholesale-focused operations ensure you get the reliable equipment your operation depends on.

Contact HONESTBEE today to discuss your wholesale needs and ensure every frame you build is built to last.

Visual Guide

Related Products

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- HONESTBEE Professional Frame Wiring Board and Jig

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

People Also Ask

- When should I throw away my bee frame? A Guide to Hive Health & Frame Rotation

- Can I reuse old frames? A practical guide to saving money and reducing waste

- How many frames fit in a 10 frame hive? A Guide to Maximizing Your Hive's Potential

- What are bee frames, and how do they relate to box sizes? A Guide to the Langstroth Hive System

- Why are wired frames necessary when executing the shook swarm technique? Ensure Stability in Your Commercial Apiary