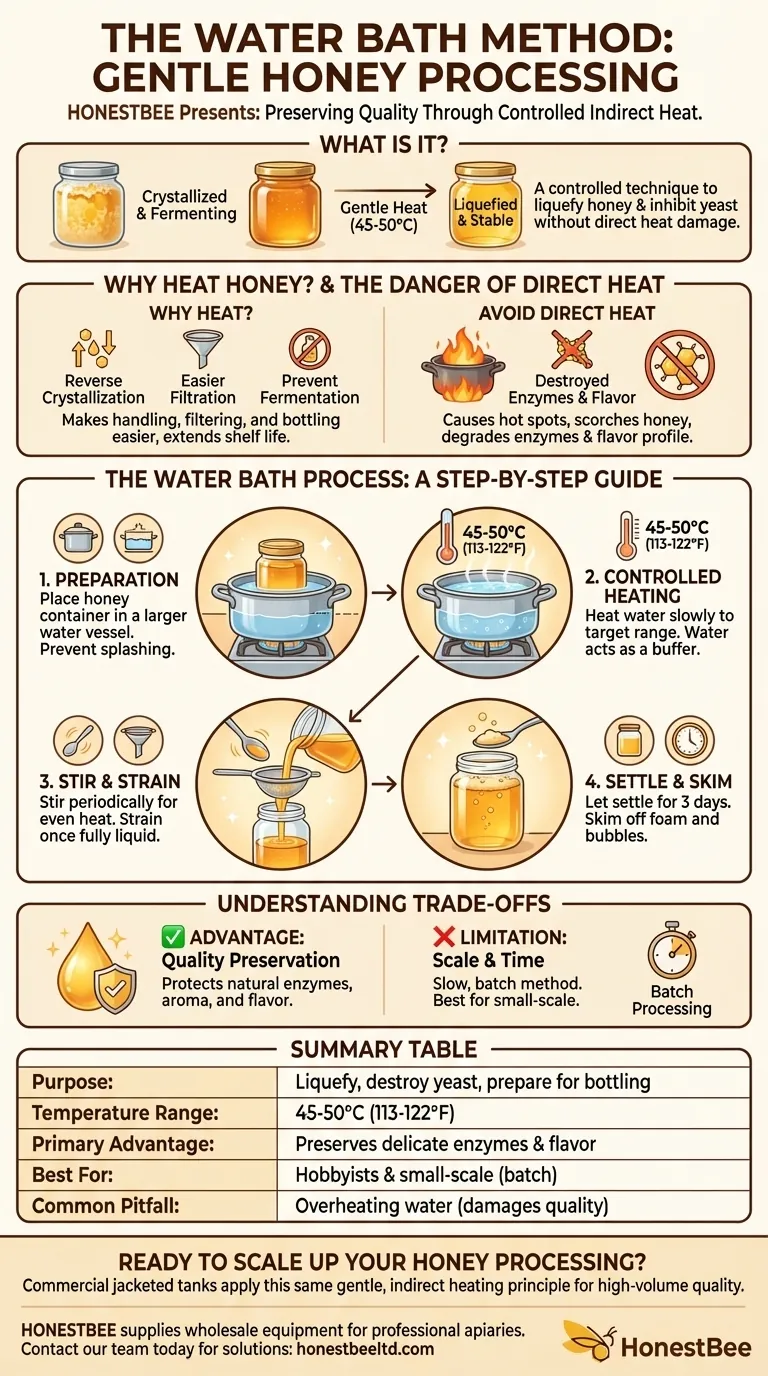

The water bath method is a controlled, indirect heating technique used in honey processing to gently liquefy crystallized honey and prepare it for bottling. It involves placing a container of honey into a larger vessel of warm water, typically heated to 45-50°C. This process makes the honey fluid enough for straining, destroys naturally occurring yeasts to prevent fermentation, and accomplishes this without the damaging effects of direct heat.

The core challenge with stored honey is that it crystallizes and can ferment. The water bath method solves this by using gentle, indirect heat to safely reliquefy the honey and inhibit yeast, preserving the delicate enzymes and flavors that direct, high heat would destroy.

The Role of Heat in Honey Processing

To understand the water bath method, it's essential to first understand why heat is applied to honey at all. The goal is never to "cook" the honey, but to carefully manage its physical state.

Why Heat Honey?

The primary reason for heating is to reverse crystallization. This natural process thickens honey and makes it difficult to handle.

Gentle heating returns the honey to a liquid state, making it much easier to filter out impurities like wax particles and to bottle cleanly.

A secondary benefit is the destruction of osmophilic yeasts. Heating the honey sufficiently helps prevent fermentation, extending its shelf life.

The Critical Danger of Direct Heat

Applying heat directly to a pot of honey is highly problematic. It creates hot spots that can easily scorch the honey.

This overheating degrades the honey's quality by destroying beneficial enzymes and antioxidants. It also darkens the color and alters the delicate flavor profile.

Where the Water Bath Method Fits In

The water bath is a post-extraction technique. After honey is removed from the comb (using an extractor or by crushing and straining), it may be stored.

This method is ideal for processing that stored honey, especially after it has crystallized, ensuring it can be filtered and bottled without compromising its quality.

Executing the Water Bath Method: A Guide

The elegance of the water bath method lies in its simplicity and control. It applies the same principle as large-scale, jacket-equipped warming tanks but on a smaller, more accessible scale.

Preparation and Setup

The setup involves two vessels. A smaller container holds the honey, and a larger pot holds the water.

The honey container is placed inside the larger pot, ensuring the water level is high enough to surround the honey without splashing into it.

Controlled Heating

Gently heat the water in the outer pot, using a thermometer to monitor its temperature. The target is a consistent 45-50°C (113-122°F).

The water should remain warm, never simmering or boiling. The water acts as a buffer, transferring heat evenly and slowly to the honey.

Stirring and Straining

As the honey warms and liquefies, it should be stirred gently and periodically. This ensures even heat distribution throughout the batch.

Once fully liquid, the warm honey can be poured through a fine filter, such as a cheesecloth folded over twice, to remove any remaining fine particles of beeswax or other debris.

Settling and Skimming

After straining, it is best to let the honey settle in a clean container for at least three days.

This settling period allows microscopic air bubbles and any remaining fine scum to rise to the surface, where they can be easily skimmed off before the final bottling.

Understanding the Trade-offs

While effective, the water bath method is not a universal solution. Its suitability depends entirely on your goals and scale.

The Primary Advantage: Quality Preservation

The single greatest benefit is quality control. Indirect, low-temperature heating is the safest way to liquefy honey while protecting its natural enzymes, aroma, and flavor.

The Key Limitation: Scale and Time

This is a batch processing method. It is highly effective but can be slow, making it perfectly suited for hobbyists and small-scale beekeepers.

For large commercial operations, the same principle is applied using more efficient, jacketed tanks with continuous hot-water circulation.

Common Pitfalls to Avoid

The most common mistake is overheating. Allowing the water to get too hot defeats the entire purpose of the gentle method. Always use a thermometer.

Another risk is water contamination. Be careful to prevent any water from the bath from splashing into the honey, as this can increase the moisture content and risk fermentation.

Making the Right Choice for Your Goal

Your processing technique should align directly with the state of your honey and the scale of your operation.

- If your primary focus is processing a small batch of crystallized honey: The water bath method is your ideal choice for its simplicity and gentle approach to preserving quality.

- If your primary focus is simply making fresh honey easier to filter: A brief, gentle warming using a water bath or an electric heat blanket will improve fluidity without damaging the product.

- If your primary focus is scaling up production: You should investigate dedicated equipment like jacketed honey tanks that apply the same indirect heating principles on a larger, more efficient scale.

Ultimately, mastering the gentle application of heat is the key to producing high-quality, shelf-stable honey.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Purpose | Liquefy crystallized honey, destroy yeasts, prepare for bottling |

| Temperature Range | 45-50°C (113-122°F) |

| Primary Advantage | Preserves honey's delicate enzymes, aroma, and flavor |

| Best For | Hobbyists and small-scale beekeepers (batch processing) |

| Common Pitfall | Overheating the water, which can damage honey quality |

Ready to Scale Up Your Honey Processing?

As a commercial beekeeper or distributor, you understand the importance of efficiency without compromising quality. The water bath method's principle of gentle, indirect heating is the foundation of professional-grade equipment.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the wholesale-focused supplies and equipment needed to apply these best practices on a larger scale. From jacketed warming tanks to efficient filtration systems, we provide the tools for high-volume, quality-focused honey production.

Contact our team today to discuss how our solutions can help your operation thrive.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 10L Stainless Steel Electric Honey Press Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

People Also Ask

- Why is honey sometimes heated before the filtering process? Master Viscosity Control for Efficient Honey Production

- How do heat chambers facilitate the processing of crystallized honey? Master Thermal Control for Bulk Honey

- What is the operational mechanism of applying thermal paste? Optimize Peltier Cooling and Heat Sink Efficiency

- What is the purpose of an external heater for the storage tank in a honey drying system? Boost Dehydration Efficiency

- Why is precise temperature control critical for honey heating equipment? Protect HMF Levels and Enzyme Bioactivity

- What sizes are honey heating blankets available in? Find the Perfect Fit for Your Pails and Drums

- What are the technical benefits of using sealed water bags as thermal storage in beehives? Boost Climate Control Efficiency

- What are the technical advantages of using water bath heating equipment in honey processing? Preserve Quality & Purity