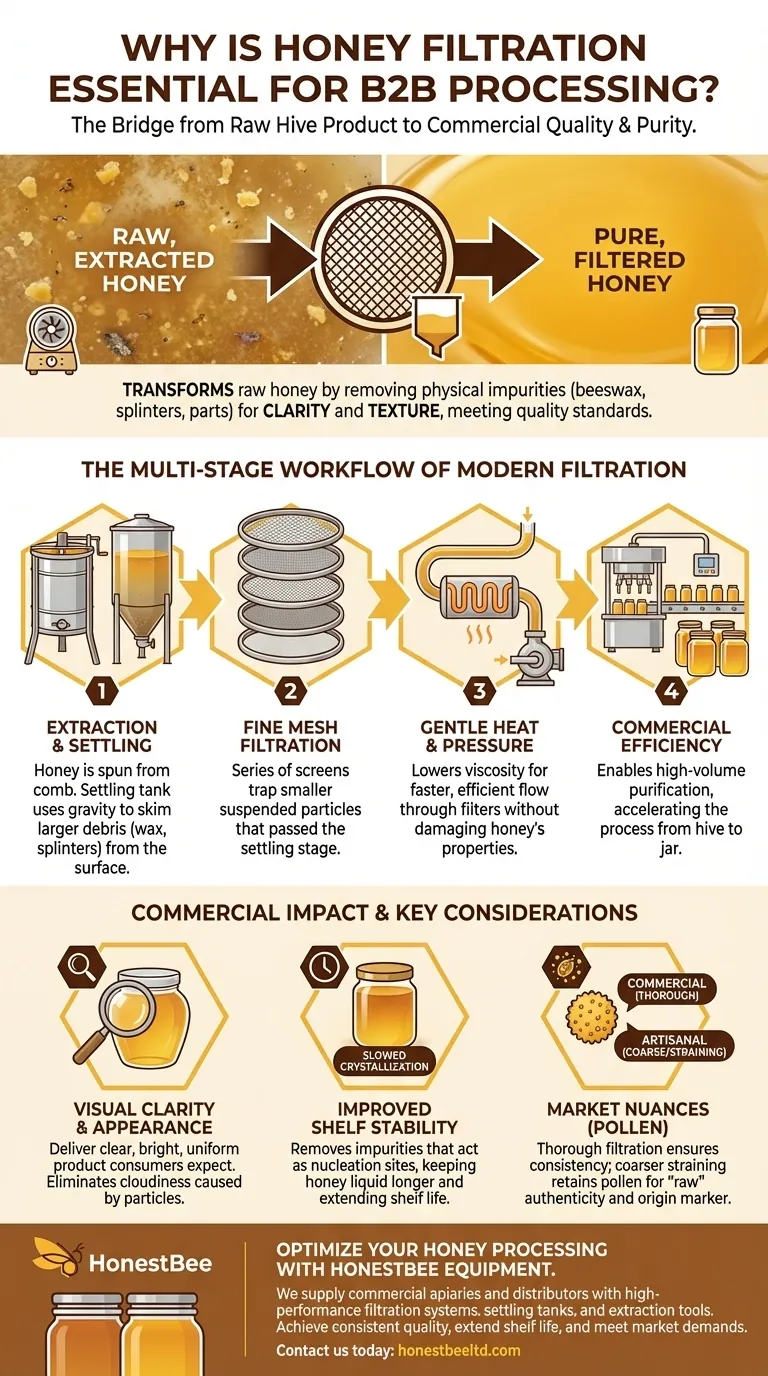

At its core, filtering is the essential step that transforms raw, extracted honey into a stable, pure, and commercially viable product. It is a non-negotiable quality control measure that removes a wide range of physical impurities—from beeswax and wood splinters to other debris from the hive—that would otherwise compromise the honey's clarity, texture, and shelf life.

While extraction gets honey out of the comb, filtration is what makes it ready for the consumer. It is a purification process designed to meet quality standards and consumer expectations for a clean and visually appealing product.

Filtration's Place in Honey Processing

Honey processing is a multi-step workflow designed to move honey from the hive to the jar efficiently and safely. Filtration sits at the very center of this process.

From Extraction to Purification

The journey begins after beekeepers collect honeycombs. These frames are uncapped and placed in a honey extractor, which uses centrifugal force to spin the honey out of the wax cells.

This raw, extracted honey is not yet ready for bottling. It contains a mixture of suspended particles that must be removed.

The Primary Goal: Removing Impurities

The fundamental purpose of filtration is to remove all unwanted physical matter. This includes beeswax particles, fragments of the hive, bee parts, and other small debris.

Failing to remove these particles results in a product that is visually unappealing and can have an inconsistent texture.

The Mechanics of Modern Honey Filtration

Filtration is more than just pouring honey through a single screen. Commercial operations use a systematic, multi-stage approach to ensure purity and efficiency.

Step 1: The Settling Tank

Before fine filtering, honey is often held in a settling tank. Here, the principle of gravity works its magic.

Being less dense, many of the larger particles, like wax and splinters, float to the surface where they can be easily skimmed off. This pre-cleans the honey and reduces the load on the finer filters.

Step 2: Fine Mesh Filtration

After settling, the honey is passed through a series of fine mesh filters, typically made of nylon or metal. These screens are designed to catch the smaller suspended particles that did not separate in the settling tank.

The Role of Gentle Heat

To aid the process, honey is often gently heated. This is not pasteurization. The goal is simply to lower the honey's viscosity (make it more fluid).

Warmer honey flows more easily and quickly through the fine mesh filters, preventing clogs and speeding up the operation without damaging the honey's natural properties.

Using Pressure to Enhance Efficiency

In larger-scale operations, high-pressure pumps may be used to push the honey through the filtration system. This significantly accelerates the process, allowing for a higher volume of honey to be purified in less time.

Understanding the Trade-offs and Commercial Impact

Filtration is not just a cleaning step; it directly influences the final product's marketability and stability. However, the degree of filtration is a key consideration.

Enhancing Clarity and Appearance

The most immediate impact of filtration is on visual clarity. Consumers overwhelmingly associate high-quality honey with a clear, bright, and uniform appearance. Filtration delivers this by removing the particles that cause cloudiness.

Improving Shelf Stability

Certain impurities, especially fine wax particles, can act as nucleation sites, encouraging and accelerating the natural process of crystallization. By removing them, filtration helps keep the honey in a liquid state for longer, extending its shelf life on the store shelf and in the pantry.

The Consideration of Pollen

While removing debris is critical, the removal of pollen is a more nuanced topic. Standard filtration removes some pollen along with other particles. More aggressive methods, known as ultrafiltration, remove nearly all of it.

Because pollen is a key marker for identifying a honey's floral source and geographic origin, its removal is a point of differentiation. Artisanal or "raw" honey producers often use a coarser straining method specifically to retain pollen.

Applying This to Your Goal

Understanding the purpose of filtration allows you to make more informed decisions, whether you are producing, purchasing, or selling honey.

- If your primary focus is a large-scale commercial product: Thorough filtration is non-negotiable to ensure visual consistency, long-term stability, and broad consumer appeal.

- If your primary focus is artisanal or "raw" honey: A less intensive straining process is preferred to retain natural elements like pollen, which serves as a mark of authenticity.

- If your primary focus is processing efficiency: Integrating gentle heat and pressure systems is key to handling large volumes of honey effectively.

Ultimately, filtration is the critical bridge between the raw hive product and the polished honey you find on the shelf.

Summary Table:

| Filtration Purpose | Key Benefit | Common Method |

|---|---|---|

| Remove Impurities | Improves clarity & texture | Fine mesh filters |

| Enhance Stability | Slows crystallization | Gentle heat & settling tanks |

| Boost Efficiency | Speeds up large-scale processing | High-pressure pumps |

| Meet Standards | Ensures consumer appeal & safety | Multi-stage filtration systems |

Ready to optimize your honey processing with professional-grade filtration equipment?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance filtration systems, settling tanks, and extraction tools designed for maximum efficiency and purity. Our wholesale-focused solutions help you achieve consistent quality, extend shelf life, and meet market demands.

Contact us today to discuss your specific needs and discover how our equipment can enhance your honey's quality and your operation's profitability.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- What are the advantages of using industrial honey filtration and temperature-controlled storage? Ensure Retail Quality

- Can raw honey be filtered? Unlock the Truth About Processing & Purity

- What are the technical advantages of using a vacuum filtration system? Speed and Clarity for Separating Extracts

- How does professional filtration equipment ensure the quality stability of honey? Secure Purity and Longer Shelf Life

- What is the overall importance of using the right equipment in honey filtering? Boost Quality & Marketability

- How do industrial-grade honey filtration systems affect quality? Maximize Marketability & Pureness

- What types of equipment are used in honey filtering? Build an Efficient System for Pure, Marketable Honey

- What types of impurities does a honey filtering machine remove? Enhance Honey Clarity and Shelf Life