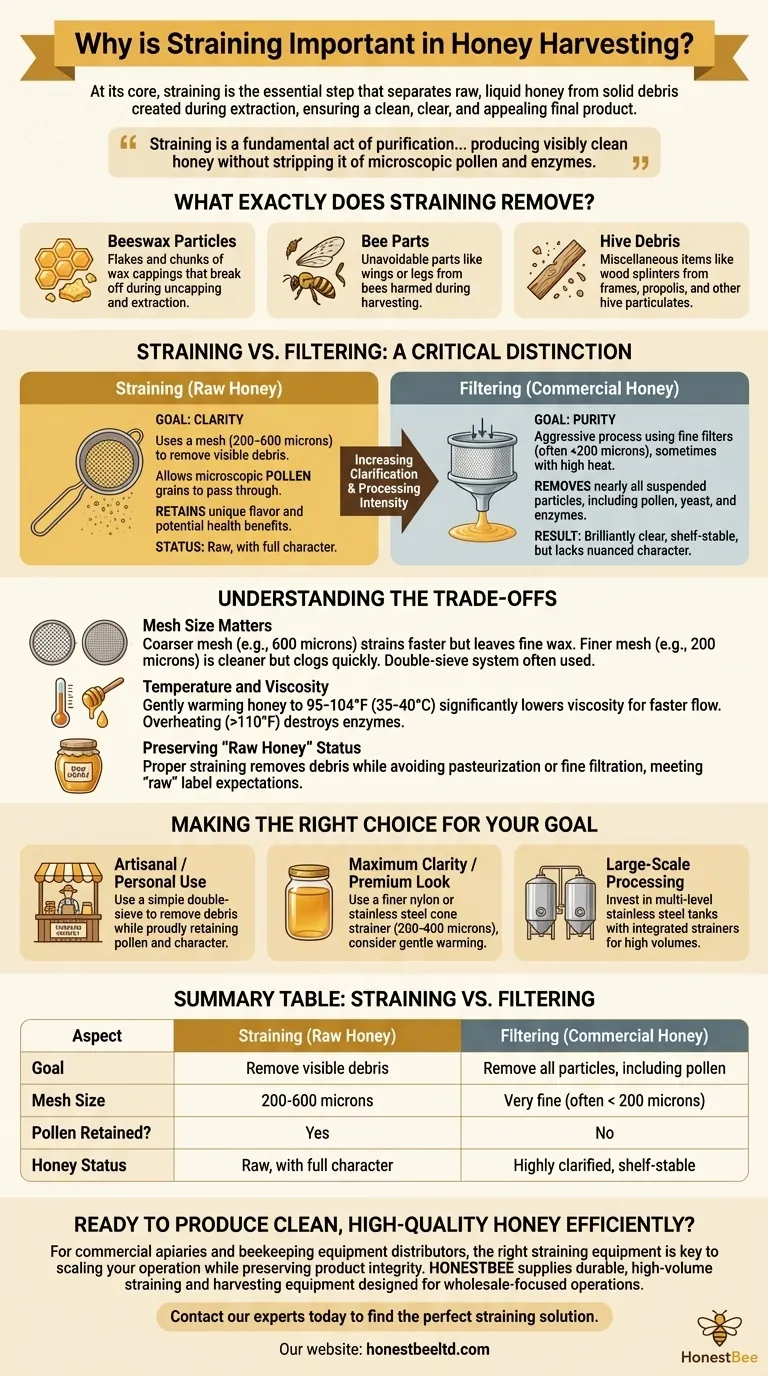

At its core, straining is the essential step in honey harvesting that separates raw, liquid honey from the solid debris created during extraction. This simple mechanical process ensures the final product is clean, clear, and appealing, removing visible impurities like beeswax particles, wood splinters from the frames, and even stray bee parts.

Straining is a fundamental act of purification in honey production. The goal is to produce visibly clean honey without stripping it of the microscopic pollen and enzymes that define its unique character and nutritional value.

What Exactly Does Straining Remove?

When honey is extracted from the comb—whether by crushing or centrifugal force—it inevitably gets mixed with various materials from the hive. Straining is designed to catch these specific, unwanted additions.

Beeswax Particles

The most common material removed is beeswax. During the uncapping and extraction process, small flakes and chunks of wax cappings break off and become suspended in the honey.

Bee Parts

While unfortunate, it is common for bees to be harmed during the harvesting process. Straining ensures that wings, legs, or other bee parts do not end up in the final jar, which is critical for consumer acceptance.

Hive Debris

Other miscellaneous items can find their way into the honey. This can include small splinters of wood from the frames, propolis (a resinous bee glue), and other particulates that don't belong in the finished product.

Straining vs. Filtering: A Critical Distinction

While often used interchangeably by beginners, straining and filtering are two very different processes with different outcomes. Understanding this difference is key to defining the quality of your honey.

The Goal of Straining: Clarity

Straining uses a mesh material, like a stainless steel screen or nylon cloth, to remove only the visible debris. The mesh size is typically between 200 and 600 microns.

This process is coarse enough to let important microscopic elements, such as pollen grains, pass through. This is crucial for retaining the honey's unique flavor profile and for anyone seeking the potential health benefits associated with local pollen.

The Goal of Filtering: Purity

Filtering is a much more aggressive process, often used in large-scale commercial operations. It involves forcing honey, sometimes under high heat and pressure, through a very fine filter.

This removes not only debris but also nearly all suspended particles, including pollen, yeast, and some enzymes. The result is a brilliantly clear, shelf-stable product that resists crystallization but lacks the nuanced character of raw honey.

Understanding the Trade-offs

Effective straining requires balancing purity with practicality. Several factors influence the outcome.

Mesh Size Matters

A coarser mesh (e.g., 600 microns) will strain honey faster but may let very fine wax particles through. A finer mesh (e.g., 200 microns) produces exceptionally clean honey but can clog quickly, slowing down the entire process. Many beekeepers use a double-sieve system, with a coarse strainer on top of a finer one.

Temperature and Viscosity

Honey is viscous and strains slowly at room temperature. Gently warming your honey to around 95-104°F (35-40°C) will significantly lower its viscosity, allowing it to flow through the strainer much more easily.

Be warned: overheating honey (above 110°F or 43°C) will begin to destroy its beneficial enzymes and delicate aromas, effectively negating the benefits of keeping it "raw."

Preserving "Raw Honey" Status

For honey to be labeled and sold as raw, it cannot be pasteurized (heated to high temperatures) or finely filtered. Proper straining is the accepted method for cleaning raw honey while preserving the qualities customers expect from that label.

Making the Right Choice for Your Goal

Your straining method should align directly with your final objective.

- If your primary focus is artisanal honey for personal use or a farmer's market: Use a simple double-sieve to remove debris while proudly retaining all the pollen and character of raw honey.

- If your primary focus is achieving maximum clarity for a premium look: Use a finer nylon or stainless steel cone strainer (200-400 microns) and consider gently warming the honey to speed up the process.

- If your primary focus is large-scale, efficient processing: Invest in a multi-level stainless steel tank with integrated strainers to handle high volumes effectively.

Ultimately, proper straining is the mark of a careful beekeeper who respects both the product and the consumer.

Summary Table:

| Aspect | Straining (Raw Honey) | Filtering (Commercial Honey) |

|---|---|---|

| Goal | Remove visible debris | Remove all particles, including pollen |

| Mesh Size | 200-600 microns | Very fine (often < 200 microns) |

| Pollen Retained? | Yes | No |

| Honey Status | Raw, with full character | Highly clarified, shelf-stable |

Ready to produce clean, high-quality honey efficiently?

For commercial apiaries and beekeeping equipment distributors, the right straining equipment is key to scaling your operation while preserving product integrity. HONESTBEE supplies durable, high-volume straining and harvesting equipment designed for wholesale-focused operations.

Contact our experts today to find the perfect straining solution for your honey production goals and volume.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How does a multi-layer stainless steel honey strainer improve quality? Ensure Pure, Professional-Grade Honey Results

- What is the function of a plastic double sieve in honey filtration? Ensure Pure, High-Quality Raw Honey Results

- What is the crush and strain method for extracting honey? A Simple Guide to Low-Cost Honey Harvesting

- What is the function of a 0.5mm fine mesh sieve in wild honey? Clean Your Honey While Preserving Enzyme Activity

- Why are dual filtration sieves used in honey processing? Balance Purity & Nutrition for Professional Honey Production