Yes, in many cases, a honey filling machine can be used to fill cosmetic products. The feasibility, however, depends entirely on whether the cosmetic product's physical properties—specifically its viscosity—are compatible with the machine's filling mechanism. Piston-style fillers, which are common for honey, are often well-suited for thick cosmetic creams, lotions, and gels.

The core principle is that the machine is designed for a specific liquid behavior, not a specific product. A piston filler designed for viscous honey can effectively handle viscous cosmetics, but it is not a universal solution for all products.

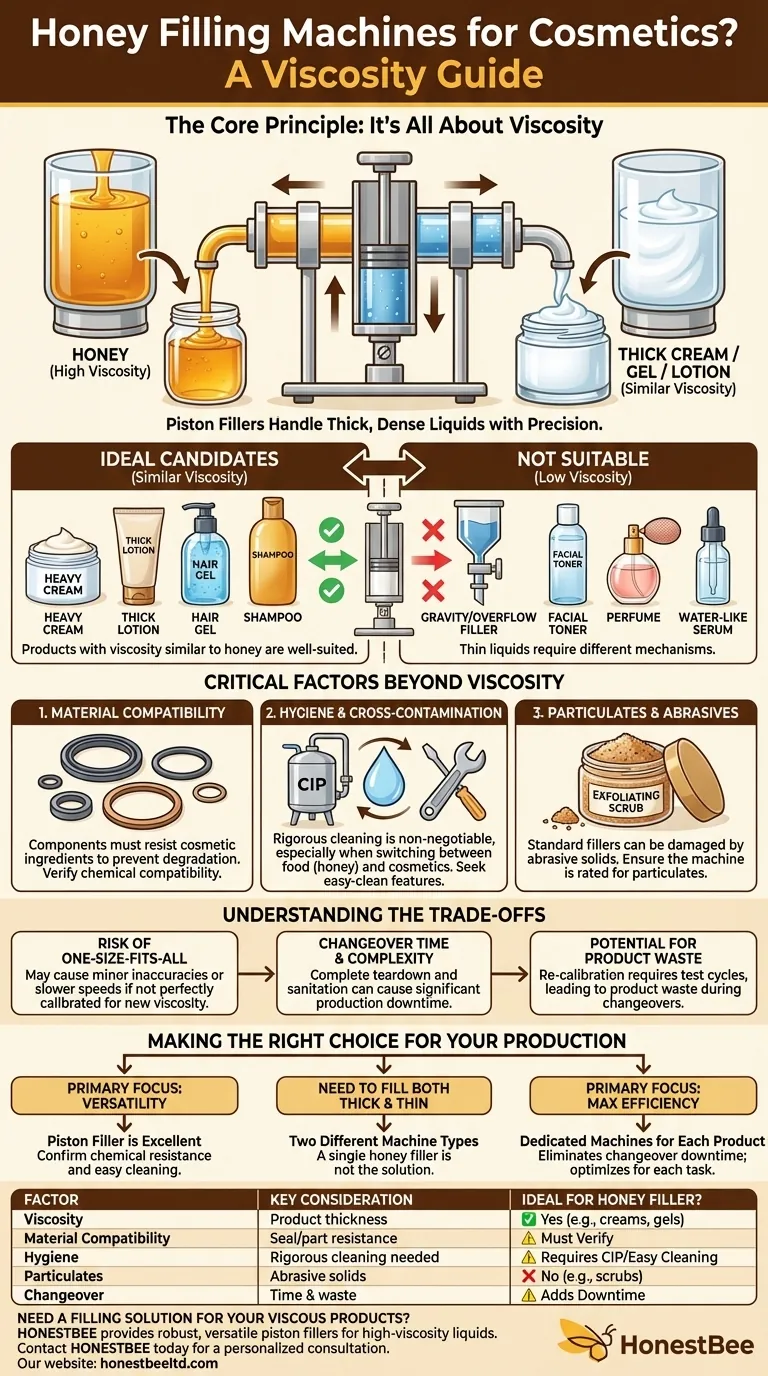

The Core Principle: It's All About Viscosity

The decision to use a honey filler for cosmetics has little to do with the product category and everything to do with its thickness, or viscosity.

How Piston Fillers Work

Most honey fillers use a piston filling mechanism. This system operates by drawing a precise volume of product into a cylinder and then pushing it out through a nozzle into the container.

This method is highly accurate and is specifically engineered to handle thick, dense liquids that do not flow easily on their own, making it ideal for honey.

Matching Product to Machine

Because they are designed for viscosity, these piston fillers are also an excellent match for many cosmetic products.

Products like heavy creams, thick lotions, gels, and shampoos have a viscosity similar to honey and can be filled accurately and efficiently using the same machine.

However, these machines are not suitable for low-viscosity (thin) liquids. Products like facial toners, perfumes, or water-like serums would not work well with a typical piston filler and often require a different mechanism, such as a gravity or overflow filler.

Critical Factors Beyond Viscosity

While viscosity is the primary consideration, several other technical factors must be verified before using a honey filler for cosmetics.

Material Compatibility

The machine's components—including seals, gaskets, and tubing—must be chemically compatible with the ingredients in your cosmetic formulas. Certain cosmetic ingredients could potentially degrade plastics or rubbers not rated for them.

Hygiene and Cross-Contamination

If you plan to switch between filling honey (a food product) and cosmetics, rigorous cleaning is non-negotiable. Look for machines that are easy to disassemble for cleaning or feature Clean-In-Place (CIP) capabilities to prevent any cross-contamination.

Particulates and Abrasives

Some cosmetics, such as exfoliating scrubs, contain solid particulates. A standard honey filler is not designed for this and could be damaged by abrasive materials. Ensure the machine is rated to handle solids if you plan to fill such products.

Understanding the Trade-offs

Using one machine for multiple product types introduces compromises that you must weigh against the cost savings.

The Risk of a "One-Size-Fits-All" Approach

A machine perfectly calibrated for the specific density of honey might operate less efficiently when filling a cream with a different viscosity. This can lead to minor inaccuracies or slower production speeds.

Changeover Time and Complexity

Switching from honey to shampoo requires more than a simple rinse. A complete teardown and sanitation process can take significant time, creating production downtime that may offset the initial savings of buying a single machine.

Potential for Product Waste

Each time you switch product types, you will need to re-calibrate the machine's fill volume. This process often involves running several test cycles, which results in a small amount of wasted product during each changeover.

Making the Right Choice for Your Production

To determine if a multi-purpose filler is right for you, evaluate your primary production goals.

- If your primary focus is versatility for viscous products: A piston filler is an excellent choice, but confirm it is built with chemically resistant materials and is designed for easy and thorough cleaning.

- If you need to fill both thick creams and thin liquids: A single honey filler is not the solution. You will need two different types of filling machines to handle the wide range in viscosity.

- If your primary focus is maximum operational efficiency: Using dedicated machines for each core product line will eliminate changeover downtime and ensure each machine is perfectly optimized for its task.

By focusing on product viscosity and the practical realities of changeover, you can make a sound investment in your production line's future.

Summary Table:

| Factor | Key Consideration | Ideal for Honey Filler? |

|---|---|---|

| Viscosity | Product thickness (e.g., honey, thick creams, gels). | ✅ Yes |

| Material Compatibility | Machine seals and parts must resist cosmetic ingredients. | ⚠️ Must Verify |

| Hygiene | Rigorous cleaning needed to prevent cross-contamination. | ⚠️ Requires CIP/Easy Cleaning |

| Particulates | Products with abrasive solids (e.g., scrubs). | ❌ No |

| Changeover | Time and product waste when switching product types. | ⚠️ Adds Downtime |

Need a filling solution for your viscous products?

Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE's wholesale-focused operations provide robust, versatile piston fillers designed for high-viscosity liquids like honey, creams, and lotions. Our experts can help you select the right equipment to maximize your production line's efficiency and versatility.

Contact HONESTBEE today for a personalized consultation and discover the right filling solution for your business.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

People Also Ask

- What function do industrial honey filling machines perform? Essential Export Infrastructure for Beekeeping Commercials

- What are the advantages of utilizing industrial-grade automated filling machines? Maximize Your Honey Yield and Quality

- How does the use of professional automated honey-filling machines benefit urban honey production? Scale Your Apiary

- How does the use of professional honey filtration and filling machinery facilitate international honey exports?

- What does a filling machine do? Boost Your Packaging Line's Speed and Accuracy

- What are the advantages of using high-precision filling machines when converting honey into commercial merchandise?

- What types of filling and packing machines are available for different scales of honey production? Expert Solutions

- How do industrial-grade filling and packaging machines contribute to the market value of certified honey? Unlock Premium Growth