Filling & Bottling

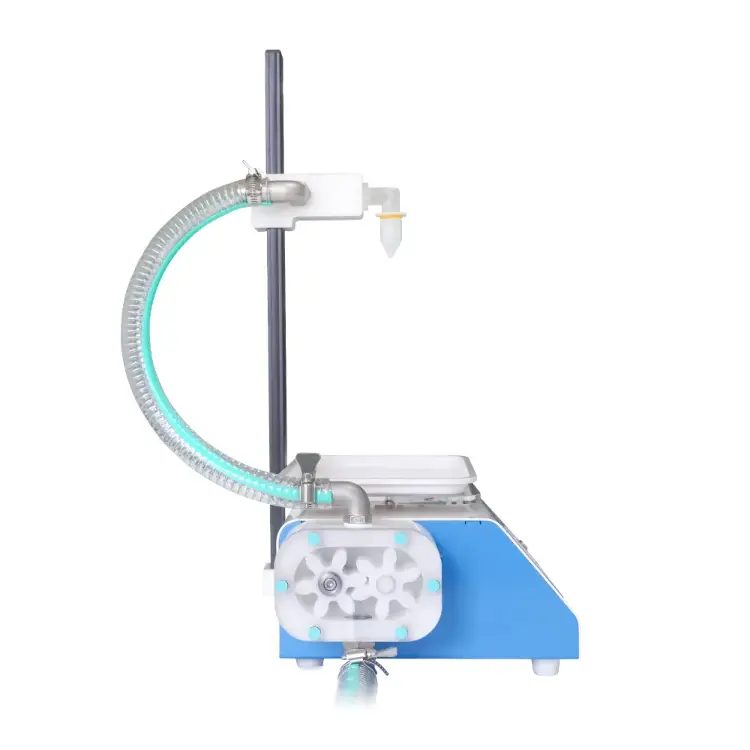

Semi Automatic Small Honey Bottle Filling Machine Honey Filler

Item Number : HFM-5

Price varies based on specs and customizations

- Filling Height

- 0-32cm adjustable

- Filling Weight Range

- 50-10000 grams

- Filling Efficiency

- 500g honey: 360 bottles/hour

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application of Semi-Automatic Honey Filling Machine

The semi-automatic honey filling machine is an essential piece of equipment for honey producers and packaging companies. It is designed to streamline the process of filling honey into bottles, ensuring efficiency and precision. This machine is particularly useful for small to medium-sized honey producers who require a reliable and cost-effective solution for their packaging needs.

One of the primary applications of this machine is in the filling of honey into various types of bottles, ranging from small 50-gram containers to larger 10,000-gram bottles. This versatility makes it suitable for a wide range of honey products, from single-use travel packs to bulk honey containers. The machine is also capable of handling honey with a Baume degree below 43 degrees, ensuring that it can process a variety of honey viscosities.

Overall, the semi-automatic honey filling machine is a versatile and efficient solution for honey producers looking to improve their packaging process. Its ability to handle a wide range of bottle sizes and honey viscosities, combined with its ease of operation, makes it an invaluable tool for any honey production facility.

Features of Semi-Automatic Honey Filling Machine

The semi-automatic honey filling machine is packed with features that make it a standout choice for honey producers. Here are some of the key features that set this machine apart:

- Adjustable Filling Height: The machine offers a filling height range of 0-32 cm, allowing it to accommodate various bottle sizes and shapes.

- Wide Filling Weight Range: It is capable of filling honey into bottles ranging from 50 to 10,000 grams, making it suitable for a variety of packaging needs.

- High Filling Efficiency: The machine can fill 360 bottles per hour with 500g of honey and 240 bottles per hour with 1000g of honey, ensuring high productivity.

- Precision Filling: With a filling error of only 1-3 grams, the machine ensures that each bottle is filled with the exact amount of honey required.

- Counting Function: The machine includes a counting function, which helps in keeping track of the number of bottles filled.

- No Air Compressor Required: The machine operates without the need for an air compressor, making it easy to operate and carry.

- English Operation Interface: The machine features an English operation interface, making it user-friendly for operators around the world.

- Manual and Automatic Modes: The machine can be switched between manual and automatic modes, providing flexibility in operation.

These features make the semi-automatic honey filling machine a reliable and efficient solution for honey producers, ensuring that they can meet their packaging needs with ease and precision.

Advantages of Semi-Automatic Honey Filling Machine

The semi-automatic honey filling machine offers numerous advantages that make it a valuable investment for honey producers. Here are some of the key benefits:

- High Production Capacity: The machine is capable of filling up to 360 bottles per hour with 500g of honey and 240 bottles per hour with 1000g of honey, ensuring high productivity.

- Precision and Accuracy: With a filling error of only 1-3 grams, the machine ensures that each bottle is filled with the exact amount of honey required, reducing waste and improving efficiency.

- Versatility: The machine can handle a wide range of bottle sizes, from 50 to 10,000 grams, and various honey viscosities, making it suitable for different packaging needs.

- Ease of Operation: The machine features an English operation interface and can be switched between manual and automatic modes, making it user-friendly and easy to operate.

- Hygienic Design: The machine is designed to prevent contamination, ensuring that the honey remains fresh and safe for consumption.

- Durable Construction: Built with high-quality materials, the machine is durable and reliable, ensuring long-term use with minimal maintenance.

- Portability: The machine operates without the need for an air compressor, making it easy to carry and set up in different locations.

These advantages make the semi-automatic honey filling machine an essential tool for honey producers, ensuring that they can meet their packaging needs with efficiency, precision, and ease.

Technical specifications

| Parameter | Specification |

|---|---|

| Voltage | 100-240V, 12V |

| Filling Height | 0-32cm adjustable |

| Available Honey | Baume degree below 43 degrees, 15 ℃ fluidity honey |

| Filling Weight Range | Suitable for 50-10000 grams of various honey bottles |

| Rated Power | 120W |

| Filling Efficiency |

500g honey: 360 bottles/hour; 1000g honey: 240 bottles/hour |

| Filling Error | 1-3g |

| Counting Function | Yes |

| Operation Interface | English |

| Mode | Manual mode and automatic mode |

FAQ

What Are The Main Applications Of A Honey Filling Machine?

What Are The Main Applications Of Honey Packaging Machines?

What Are The Main Applications Of A Honey Bottling Machine?

What Are The Key Features Of A Honey Filling Machine?

What Types Of Honey Packaging Machines Are Available?

What Are The Key Features Of A Honey Bottling Machine?

How Does A Honey Filling Machine Work?

How Does A Honey Packaging Machine Work?

How Does A Honey Bottling Machine Work?

What Are The Advantages Of Using A Honey Filling Machine?

What Are The Advantages Of Using A Honey Packaging Machine?

What Are The Advantages Of Using A Honey Bottling Machine?

Can Honey Filling Machines Be Used For Products Other Than Honey?

What Features Should I Consider When Choosing A Honey Packaging Machine?

4.8 / 5

This machine is a game-changer! Precise, efficient, and easy to use. Highly recommend for small honey producers.

4.9 / 5

Incredible value for money. The accuracy and speed have significantly boosted our production.

4.7 / 5

The versatility of this machine is unmatched. Handles all bottle sizes with ease. A must-have!

4.9 / 5

Fast delivery and excellent quality. Our honey packaging has never been this efficient.

4.8 / 5

Durable and reliable. The English interface makes it super user-friendly. Highly satisfied!

4.7 / 5

The hygienic design ensures our honey stays fresh. A fantastic investment for any producer.

4.9 / 5

Portable and powerful. Perfect for our small-scale operations. Highly recommended!

4.8 / 5

The counting function is a lifesaver. This machine has streamlined our entire process.

4.7 / 5

The precision filling is spot on. Reduced our waste and improved efficiency. Great machine!

4.9 / 5

High production capacity with minimal errors. A must for anyone serious about honey packaging.

4.8 / 5

The manual and automatic modes provide great flexibility. Very impressed with its performance.

4.7 / 5

No air compressor needed! Easy to carry and set up. Perfect for our mobile operations.

4.9 / 5

The adjustable filling height is a brilliant feature. Handles all our bottle sizes effortlessly.

4.8 / 5

The machine is built to last. High-quality materials ensure long-term use. Very happy with this purchase.

4.7 / 5

The English interface is a big plus. Easy to operate and highly efficient. Great value for money.

4.9 / 5

This machine has transformed our packaging process. Fast, precise, and reliable. Highly recommend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

Optimize honey packaging with our efficient Honey Filling Machine. Precise, fast, and easy to use. Boost production now!

Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

Optimize honey quality with the Honey Dryer, designed for small-scale beekeepers. Efficient, durable, and cost-effective. Explore now!

Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

Discover the Honey Bottling Machine for precise, hygienic honey packaging. Ideal for food, cosmetics, and pharmaceutical industries. Efficient and durable.

10L Stainless Steel Electric Honey Press Machine

10L Stainless Steel Electric Honey Press for efficient honey extraction. Durable, easy to clean, and preserves natural honey quality. Perfect for beekeepers.

Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

Electric Honey Press Machine: Efficiently separate honey and wax with 10-ton pressure. Ideal for beekeepers and DIY projects. Durable 304 stainless steel, 10kg capacity.

Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

Manual stainless steel honey press for efficient honey, wax extraction. Durable, food-grade, user-friendly design. Perfect for beekeepers, farms, and more. Explore now!

Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

Discover the **3 Frame Manual Honey Extractor**, perfect for eco-friendly, gentle, and efficient honey extraction. Ideal for small-scale beekeepers.

24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

Optimize honey extraction with our 24-frame stainless steel honey extractor. High-capacity, durable, and customizable for commercial beekeeping. Explore now!

Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

Revolutionize beekeeping with the honey flow beehive. Enjoy stress-free, bee-friendly honey extraction using the Flow Key. Perfect for backyard beekeepers.

Stainless Steel Triangle Support Honey Strainer and Filters

Discover the stainless steel triangle support honey strainer, perfect for filtering raw honey. Durable, efficient, and easy to clean, ideal for beekeepers.

Commercial 48-Frame Stainless Steel Honey Extractor

Explore the **electric 48-frame honey extractor**, a durable stainless steel tool for efficient honey processing. Ideal for commercial beekeeping.

Plastic Hand Crank 2 Frame Honey Extractor Low Price

Hand crank honey extractor: Efficient, eco-friendly, and portable. Ideal for Langstroth & UK frames. Manual operation, durable plastic. Perfect for small-scale beekeeping.

Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

Discover the electric honey extractor: stainless steel, 550W motor, 12-frame capacity. Perfect for efficient, gentle honey extraction. Explore now!

Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

Discover the stainless steel honey extractor and Manual 8 frame machine, ideal for efficient, large-scale honey extraction. Durable, rust-resistant, and customizable.

Honey Convey Pump Screw Honey Pump for Viscous Liquid

Optimize honey transfer with the Honey Convey Pump. Durable 304 stainless steel, screw pump mechanism, and versatile capacity options. Perfect for honey processing plants.

Stainless Steel J Hook Hive Tool for Beekeeping

J hook hive tool: Stainless steel, ergonomic design for lifting frames, scraping wax, and prying hive boxes. Essential for beekeepers.

Honeycomb Uncapping Knife for Apiculture

Discover the precision uncapping knife for efficient honeycomb wax removal. Stainless steel, 40cm length, dual-edge design. Perfect for beekeepers.

Automatic Heat Preservation 6 Frame Pro Nuc Box for Honey Bee Queen Mating

Optimize beekeeping with the 6 frame nuc box, featuring Automatic Heat Preservation, slope design, and 3.8L feeder. Ensure healthy, productive colonies. Explore now!

Double Head Beekeeping Grafting Tools for Beekeepers

Double Head Beekeeping Grafting Tools: Stainless steel, precise, efficient queen bee breeding. Essential for beekeepers.

Related Articles

Why Your Honey Filling Line is Failing—And It's Not the Machine's Fault

Struggling with inconsistent honey fills and production halts? Discover the real root cause and how to build a reliable, profitable bottling process.

How to Choose a Honey Filling Machine: Balancing Efficiency, Customization, and Cost

Learn how to choose the right honey filling machine for efficiency, customization, and cost savings in commercial honey packaging.

The 40°C Rule: How Gentle Heat Protects the Soul of Your Honey

Learn why 40°C is the crucial temperature for warming honey. Exceeding it damages enzymes and flavor—a costly mistake for commercial beekeepers.

How Automated Frame-Making Revolutionizes Beehive Production Efficiency

Discover how automated frame-making boosts beekeeping efficiency with precision grooving, tenon forming, and sustainable materials for healthier hives.

HonestBee Top & Bottom Bar Forming Machine: Precision Manufacturing for Beehive Frames

A specialized wood-forming solution for beehive frame manufacturers offering customizable precision cutting, end-shaping, and notching capabilities to enhance production efficiency.

How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

The Hive's Silent Architect: Engineering Efficiency with Beeswax Foundation

Learn how a wax roller transforms beeswax, saving bee energy, boosting productivity, and ensuring the structural integrity of the hive.