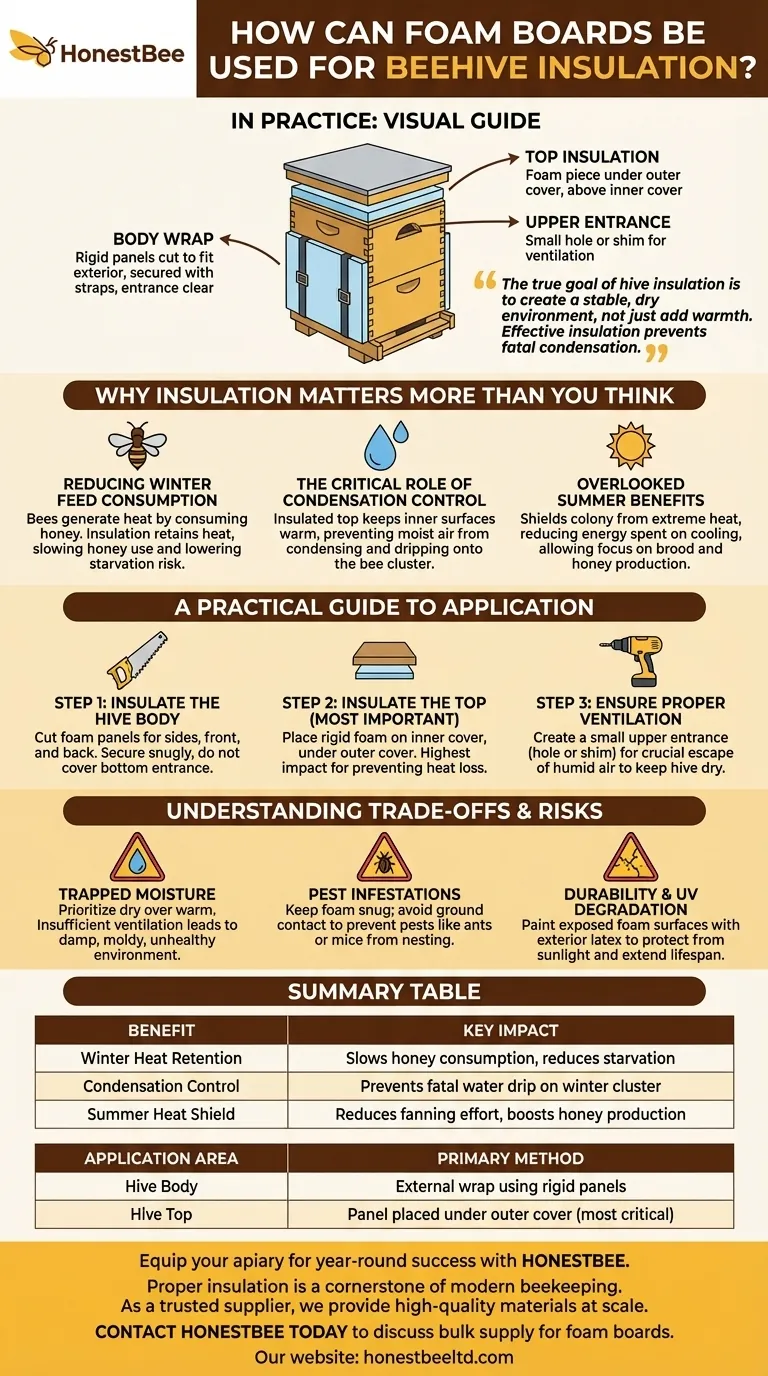

In practice, foam boards are used for beehive insulation by cutting rigid panels to fit the exterior of the hive bodies and placing a piece directly under the outer cover. These panels are then secured around the hive, typically with straps or heavy-duty tape, creating an external insulating wrap that protects the colony without altering its internal environment.

The true goal of hive insulation is not just to add warmth, but to create a stable, dry environment. Effective insulation reduces the bees' winter workload and, most importantly, helps prevent the fatal condensation that can occur inside a cold, damp hive.

Why Insulation Matters More Than You Think

A common misconception is that bees need a warm hive. In reality, bees generate their own heat by forming a cluster and vibrating their wing muscles. Insulation simply helps them retain that self-generated heat more efficiently.

Reducing Winter Feed Consumption

A honey bee colony's winter fuel is its honey stores. To generate heat, they must consume this honey.

By reducing the rate at which heat escapes the hive, insulation allows the bees to burn through their honey stores more slowly. This significantly lowers the risk of the colony starving before spring arrives.

The Critical Role of Condensation Control

As the bees cluster and respire, they release warm, moist air. When this air rises and hits a cold surface—like the inner cover—it condenses into water droplets.

This cold water can drip back down onto the cluster, chilling and killing the bees. A well-insulated top keeps the inner surface of the hive warmer than the dew point, drastically reducing or eliminating condensation. This is the single most important benefit of insulation.

Overlooked Summer Benefits

Insulation isn't just for winter. In regions with extreme summer heat, an insulated hive helps shield the colony from overheating.

This reduces the energy the bees must expend on fanning and foraging for water to cool the hive, allowing them to focus more resources on brood-rearing and honey production.

A Practical Guide to Applying Foam Board

Applying foam board is straightforward, but success lies in the details. The most common materials are rigid polystyrene or polyisocyanurate foam boards, found at any hardware store.

Step 1: Insulating the Hive Body (The Wrap)

Cut foam panels to match the height and width of your hive boxes. The goal is to create a "wrap" that covers the front, back, and sides.

Do not cover the main entrance at the bottom. The bees need clear access. Secure the panels snugly against the hive using ratchet straps or high-quality duct tape. Straps are often preferred as they are reusable and more durable.

Step 2: Insulating the Top (The Most Important Step)

The vast majority of heat loss occurs through the top of the hive. This makes top insulation the highest-impact action you can take.

Cut a piece of rigid foam to fit snugly on top of your inner cover, but underneath your telescoping outer cover. An inch or two of foam here is highly effective at preventing heat loss and stopping condensation.

Step 3: Ensuring Proper Ventilation

Insulation without ventilation is a recipe for disaster. You must provide a way for the moist air generated by the bees to escape the hive.

Creating a small upper entrance—either by drilling a 3/4-inch hole in the top box or by placing a small shim under one edge of the inner cover—provides a crucial exit path for humid air. This keeps the hive interior dry.

Understanding the Trade-offs and Risks

While beneficial, using foam board insulation requires awareness of potential pitfalls. Objectively considering these trade-offs will lead to a healthier colony.

The Danger of Trapped Moisture

If you insulate the hive but fail to provide adequate ventilation, you will trap moisture. This creates a damp, moldy environment that is extremely unhealthy for bees and can lead to the colony's demise.

Always prioritize a dry hive over a warm hive. Proper ventilation is non-negotiable.

Preventing Pest Infestations

Foam board can provide a tempting home for pests like ants or mice if not managed properly.

Ensure the foam wrap does not extend all the way to the ground, as this can create a bridge for pests. Keeping the foam snug against the hive walls minimizes gaps where insects can nest.

Durability and UV Degradation

Standard foam board will degrade and become brittle when exposed to sunlight over time.

To significantly extend its life, paint any exposed foam surfaces with a standard exterior latex paint. This protects it from UV radiation and makes it last for many seasons.

Making the Right Choice for Your Colony

Your insulation strategy should be tailored to your specific climate and goals.

- If your primary focus is surviving harsh winters: Use a full wrap on the hive bodies combined with 2 inches of foam on top of the inner cover, and ensure you have a small upper entrance for ventilation.

- If your primary focus is moisture control in a damp, mild climate: Prioritize top insulation and excellent ventilation. A wrap may be unnecessary, but keeping the top dry is critical.

- If your primary focus is a simple, low-cost improvement: Adding a single piece of 1-inch foam on top of the inner cover provides the most significant benefit for the least amount of work.

By properly insulating your hive, you create a more stable and energy-efficient home that empowers your bees to thrive through any season.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Winter Heat Retention | Slows honey consumption, reduces starvation risk |

| Condensation Control | Prevents fatal water drip on the winter cluster |

| Summer Heat Shield | Reduces fanning effort, boosts honey production |

| Application Area | Primary Method |

| Hive Body | External wrap using rigid panels |

| Hive Top | Panel placed under the outer cover (most critical) |

Equip your apiary for year-round success with HONESTBEE. Proper insulation is a cornerstone of modern, productive beekeeping. As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide the durable, high-quality materials you need to implement these best practices at scale. Let our wholesale-focused operations support the health of your colonies and the profitability of your business.

Contact HONESTBEE today to discuss your bulk supply needs for foam boards and other essential beekeeping equipment.

Visual Guide

Related Products

- Inner Beehive Cover for Beekeeping Bee Hive Inner Cover

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Drop-Style Hive Handles for Beekeeping

- HONESTBEE Classic Pry Bar Hive Tool with High Visibility Finish for Beekeeping

- Langstroth Screen Bottom Board for Beekeeping Wholesale

People Also Ask

- What are the advantages of using an inner cover in a beehive? Key Benefits for Hive Health & Beekeeper Efficiency

- What is the recommended orientation for the rim of an inner cover? Master Hive Ventilation and Insulation

- What is an inner cover in a beehive and what are its features? A Key Tool for Hive Health & Management

- What is the function of the center hole in the inner cover? Master Hive Ventilation and Feeding

- What is the role of the inner cover in a beehive? Essential Climate Control for Hive Health