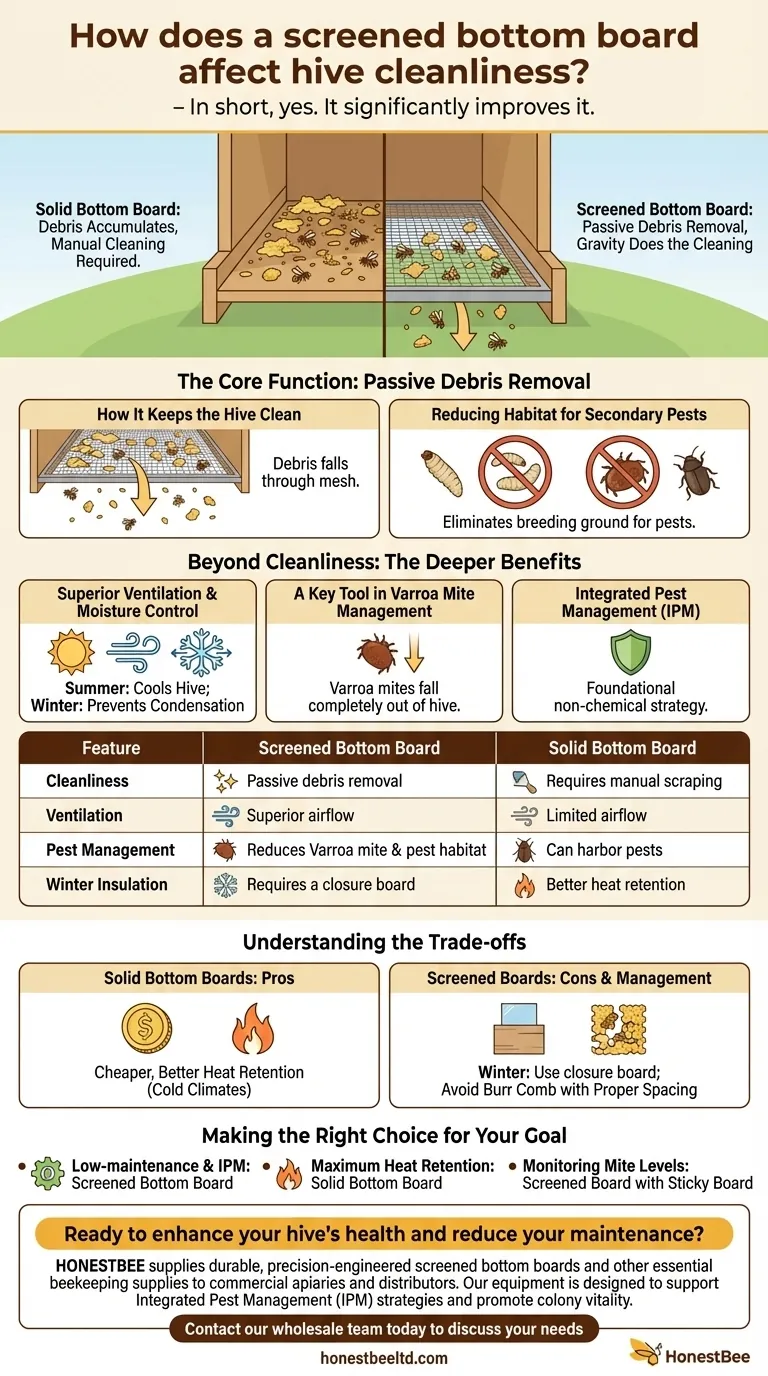

In short, yes. A screened bottom board significantly improves hive cleanliness by allowing hive debris—such as wax cappings, pollen, and deceased bees—to fall directly through the mesh floor and out of the hive. This passive cleaning system reduces the labor required by both the beekeeper and the bees to maintain a healthy internal environment.

The choice between a screened or solid bottom board is not merely about cleanliness. It is a strategic decision that impacts ventilation, pest management, and seasonal temperature regulation within the hive. Understanding these trade-offs is fundamental to proactive beekeeping.

The Core Function: Passive Debris Removal

How It Keeps the Hive Clean

A standard beehive floor, known as a solid bottom board, accumulates detritus over time. This debris must be physically scraped out by the beekeeper, typically during spring and fall inspections.

A screened bottom board replaces this solid floor with a sturdy wire mesh. This simple design allows gravity to do the cleaning for you. Small bits of debris that would otherwise collect on the floor simply fall through the screen.

Reducing Habitat for Secondary Pests

This accumulation of debris on a solid board can become a breeding ground for secondary pests like wax moth larvae and Small Hive Beetles. By constantly removing this material, a screened bottom board eliminates a key habitat for these intruders, contributing to the overall health of the colony.

Beyond Cleanliness: The Deeper Benefits

Superior Ventilation and Moisture Control

Proper airflow is critical to a colony's health. A screened bottom board provides superior ventilation, which serves two key purposes depending on the season.

During hot summer months, the increased airflow helps the colony cool the hive more efficiently. In the cold, damp winter, it allows excess moisture from the bees' respiration to escape, preventing dangerous condensation from dripping back down onto the cluster.

A Key Tool in Varroa Mite Management

The Varroa destructor mite is the single greatest threat to honey bee colonies. When mites lose their grip and fall from a bee, a screened bottom board dramatically increases the chance they will fall completely out of the hive.

While not a standalone treatment, studies suggest a screened bottom board can reduce the in-hive mite population by around 20%. It is a foundational, non-chemical component of an Integrated Pest Management (IPM) strategy.

Understanding the Trade-offs

The Case for Solid Bottom Boards

Solid bottom boards are not without their advantages. They are often cheaper to build or purchase and are better at retaining heat.

In colder climates, this heat retention may help the colony initiate brood rearing earlier in the spring, leading to a faster seasonal build-up.

Winter Management with Screened Boards

The primary drawback of a screened bottom is its potential to make the hive too cold during winter. Many beekeepers mitigate this by sliding a removable "closure board" or "corrugated plastic sign" underneath the screen during the coldest months.

This approach offers the best of both worlds: ventilation and mite control during the active season, and increased insulation during the winter.

"Broken Bee Space" and Burr Comb

If the distance between the bottom of the frames and the screen is too large, bees may be tempted to build unwanted wax, known as burr comb, in the gap. This negates the self-cleaning benefit and creates extra work. Proper equipment dimensions are essential to prevent this.

Making the Right Choice for Your Goal

Choosing your hive's foundation depends entirely on your climate and management philosophy.

- If your primary focus is low-maintenance and integrated pest management: The screened bottom board is the superior choice for its passive cleaning and mite-reduction benefits.

- If your primary focus is maximum heat retention in a harsh, cold climate: A solid bottom board may be preferable, though a screened board with a winter closure offers more flexibility.

- If your primary focus is monitoring mite levels: A screened bottom board used with a sticky board underneath is the gold standard for tracking mite fall and making treatment decisions.

Ultimately, selecting the right bottom board is a foundational decision that empowers you to better manage your hive's health and productivity.

Summary Table:

| Feature | Screened Bottom Board | Solid Bottom Board |

|---|---|---|

| Cleanliness | Passive debris removal | Requires manual scraping |

| Ventilation | Superior airflow | Limited airflow |

| Pest Management | Reduces Varroa mite & pest habitat | Can harbor pests |

| Winter Insulation | Requires a closure board | Better heat retention |

Ready to enhance your hive's health and reduce your maintenance?

HONESTBEE supplies durable, precision-engineered screened bottom boards and other essential beekeeping supplies to commercial apiaries and distributors. Our equipment is designed to support Integrated Pest Management (IPM) strategies and promote colony vitality.

Contact our wholesale team today to discuss your needs and discover how our products can contribute to your operation's success.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Solid Bottom Board Australian Pine Wood Langstroth Bottom Board for Wholesale

- Professional Grade Foldable Beehive Handles

- Stainless Steel 9 Frame Hive Spacer Durable Precise for Commercial Beekeeping

People Also Ask

- How does a screened bottom board assist with temperature control and pest management? A Key Tool for Modern Beekeeping

- What is a screened bottom board and what are its uses? Enhance Hive Ventilation & Varroa Control

- What are the overall benefits of using wire mesh for a beehive floor? Improve Hive Health & Reduce Maintenance

- What is the impact of screened bottom boards on small hive beetles? Improve Hive Health & Ventilation

- How does a screened beehive bottom board assist with non-chemical pest control? Boost Hive Health Naturally