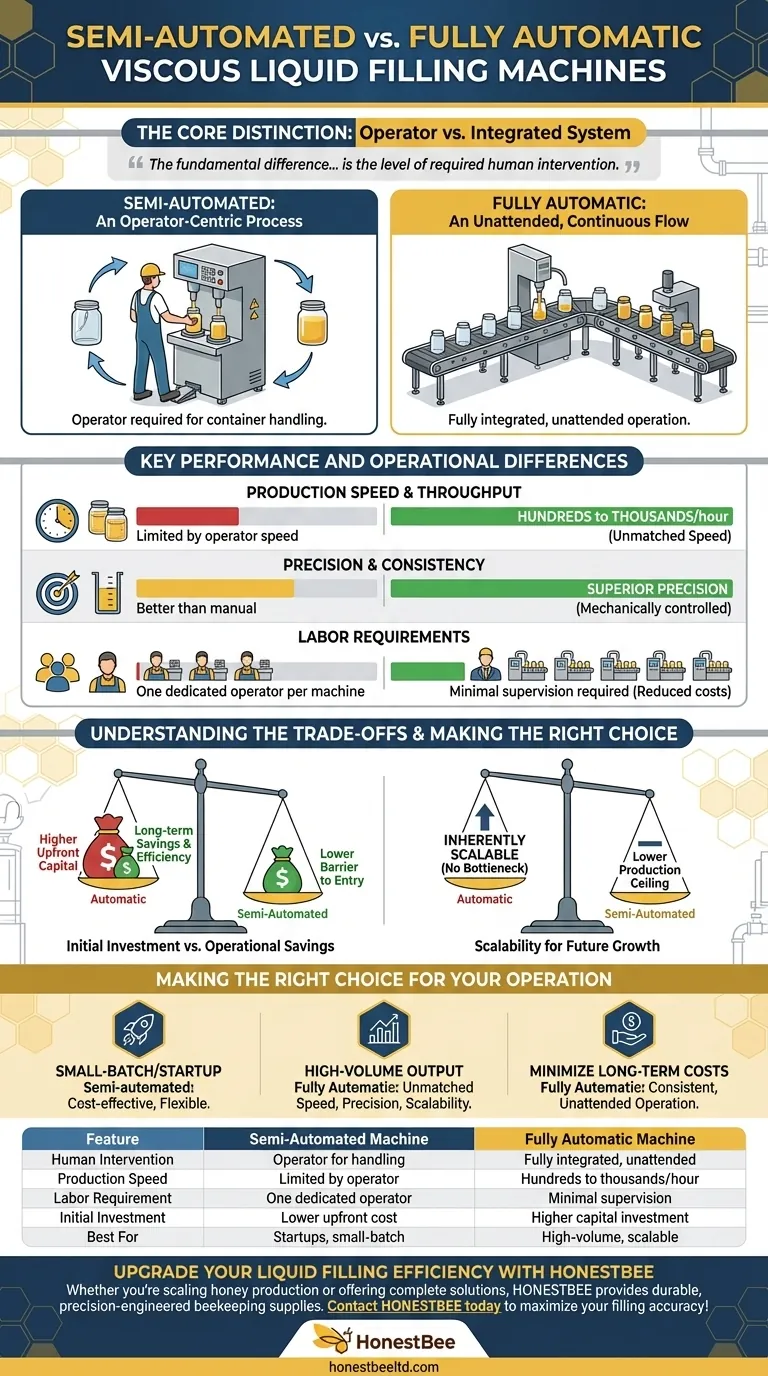

The fundamental difference between semi-automated and fully automatic viscous liquid filling machines is the level of required human intervention. While a semi-automated machine still relies on an operator to manually place and remove containers for filling, a fully automatic machine integrates every step of the process—from container handling to filling—into a single, continuous system without direct human involvement.

The decision between semi-automated and fully automatic is not merely a technical one; it is a strategic choice that balances initial investment against long-term operational costs, production speed, and the scalability required for future growth.

The Core Distinction: Operator vs. Integrated System

The primary divergence between these two machine types lies in how they handle the containers being filled. This single factor has significant downstream effects on speed, labor, and scalability.

Semi-Automated: An Operator-Centric Process

In a semi-automated setup, the machine handles the precise dispensing of the liquid, but an operator is essential to the workflow.

The operator is responsible for placing an empty container under the filling nozzle, initiating the fill cycle (often via a foot pedal), and then removing the filled container.

Fully Automatic: An Unattended, Continuous Flow

A fully automatic machine eliminates the need for a dedicated operator during the filling process. It is built around an integrated conveyor system.

This system automatically transports containers to the filling station, positions them correctly, fills them to a precise volume, and then moves them along for the next stage, such as capping or labeling.

Key Performance and Operational Differences

The level of automation directly translates into measurable differences in performance metrics that are critical for any production environment.

Production Speed and Throughput

Automatic machines are significantly faster. Unconstrained by the physical limits of human labor, they can fill hundreds or even thousands of containers per hour.

Semi-automated machines are faster than purely manual filling but are ultimately limited by the speed and stamina of the operator. They serve as a bridge between manual and fully automated production.

Precision and Consistency

While both machine types offer better accuracy than manual pouring, fully automatic machines deliver superior precision.

Because every movement and fill duration is mechanically controlled and repeatable, automatic systems eliminate the potential for human error, ensuring every container is filled to the exact same level.

Labor Requirements

A primary benefit of full automation is the reduction in direct labor costs. A single supervisor can often oversee multiple automatic lines, freeing up personnel for more value-added tasks.

Semi-automated systems still require one dedicated operator per machine to manage the container handling process.

Understanding the Trade-offs

Choosing the right machine requires an objective assessment of its costs, benefits, and alignment with your business trajectory.

Initial Investment vs. Operational Savings

Fully automatic machines represent a higher upfront capital investment. This cost is justified by long-term savings from reduced labor, minimized product waste, and higher throughput.

Semi-automated machines offer a lower barrier to entry, making them an accessible option for businesses that are just starting to scale their production.

Scalability for Future Growth

This is a critical strategic consideration. Automatic filling machines are inherently scalable and are designed to handle significant increases in production demand without becoming a bottleneck.

A semi-automated machine has a much lower production ceiling. As your business grows, you may need to purchase additional semi-automated machines—and hire more operators—to keep up.

Making the Right Choice for Your Operation

The ideal solution depends entirely on your production volume, budget, and long-term business goals.

- If your primary focus is a startup or small-batch production: A semi-automated machine provides a cost-effective entry point with the flexibility needed for frequent product changeovers.

- If your primary focus is high-volume output and maximum efficiency: A fully automatic machine is the clear choice, delivering unmatched speed, precision, and scalability for large-scale operations.

- If your primary focus is minimizing long-term labor costs and human error: The investment in a fully automatic system will yield the most significant returns through consistent, unattended operation.

Understanding these core differences empowers you to select a filling solution that not only meets your current needs but also supports your future ambitions.

Summary Table:

| Feature | Semi-Automated Machine | Fully Automatic Machine |

|---|---|---|

| Human Intervention | Operator required for container handling | Fully integrated, unattended operation |

| Production Speed | Limited by operator speed | Hundreds to thousands of containers/hour |

| Labor Requirement | One dedicated operator per machine | Minimal supervision required |

| Initial Investment | Lower upfront cost | Higher capital investment |

| Best For | Startups, small-batch production | High-volume, scalable operations |

Upgrade Your Liquid Filling Efficiency with HONESTBEE

Choosing the right filling equipment is crucial for your operation's success. Whether you're a commercial apiary scaling your honey production or a beekeeping equipment distributor looking to offer complete solutions, HONESTBEE has the expertise and wholesale-focused operations to support your growth.

We supply durable, precision-engineered beekeeping supplies and equipment designed for high-performance environments. Let us help you select the ideal viscous liquid filling solution that balances your production needs with your budget.

Contact HONESTBEE today to discuss your requirements and discover how our equipment can maximize your filling accuracy and operational efficiency!

Visual Guide

Related Products

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- In what ways do automatic filling machines impact labor costs? Cut Expenses and Boost Efficiency

- What is honey filling equipment used for? Optimize Your Bottling with Precision Automation

- What factors must industrial equipment manage for Manuka honey? Preserve MGO & UMF with Precision Filling

- How do automated honey-filling machines ensure product quality? Secure Purity for Organic Honey Production

- What are the core advantages of using automated honey-filling machines? Boost Efficiency & Precision for Your Apiary

- Why are efficiency and speed important criteria when choosing a honey packaging machine? Scale Your Production Today

- What role does commercial honey filtration and filling machinery play in export-oriented production? | HONESTBEE Guide

- What level of filling accuracy is achievable with automatic filling machines? Precision for Professional Honey Producers