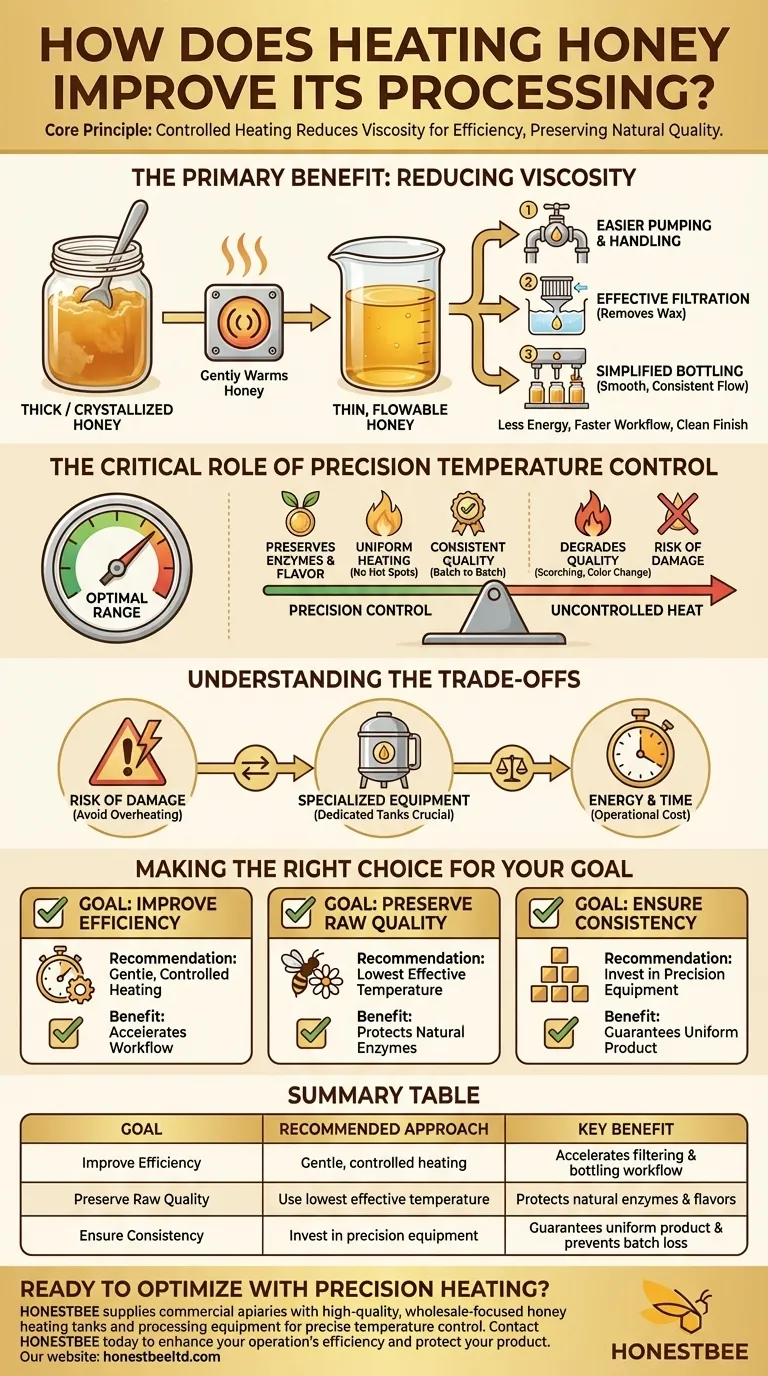

To put it simply, heating honey makes it significantly less thick and easier to work with. This reduction in viscosity is the key reason it improves processing, allowing the honey to be pumped, filtered, and bottled far more efficiently, especially when dealing with honey that is crystallized or naturally viscous.

The core principle isn't just about applying heat, but about applying it with precision. Controlled heating allows you to gain the benefits of improved fluidity for processing while critically preserving the honey's natural quality, flavor, and delicate enzymes.

The Primary Benefit: Reducing Viscosity

Viscosity is a measure of a fluid's resistance to flow. For honey, high viscosity means it is thick and slow-moving, creating challenges in a production environment.

The Challenge of Thick Honey

Thick or crystallized honey is difficult to pump through pipes and machinery. It requires more powerful equipment and can slow down the entire workflow from extraction to bottling.

How Heat Transforms Flow

By gently warming the honey, you decrease its viscosity. This makes it flow more like a thin syrup, requiring less energy to move and handle.

Facilitating Effective Filtration

Filtering honey is essential to remove impurities like wax particles. Thinner, less viscous honey passes through filters more easily, enabling a faster and more effective clarification process without requiring high pressure that can damage equipment.

Simplifying the Bottling Process

For the final step, low viscosity ensures a smooth, consistent, and rapid flow into jars or containers. This prevents bottlenecks in production and ensures a clean, professional finish.

The Critical Role of Precision Temperature Control

While heating is beneficial, how you heat the honey is the most important factor. Uncontrolled heat can do more harm than good, permanently damaging the product.

Avoiding Quality Degradation

Overheating honey degrades its delicate enzymes and can negatively alter its flavor and color. Precise temperature control ensures the honey is warmed just enough to become fluid without destroying its valuable natural properties.

Preventing Hot Spots and Scorching

Using improper heating methods can create "hot spots" where some of the honey gets too hot and scorches. A properly designed honey heating tank provides uniform heating, ensuring the entire batch is brought to the same temperature without any risk of burning.

Maintaining Consistency

Precise control allows you to set and maintain the ideal temperature for your specific type of honey. This leads to a consistent, high-quality product from batch to batch, which is essential for any commercial operation.

Understanding the Trade-offs

Applying heat is a powerful tool, but it's essential to understand the balance between workability and preservation.

The Risk of Damage

The single biggest risk is heat damage. Any temperature that is too high or applied for too long will degrade the honey. The goal is to use the lowest possible temperature for the shortest amount of time to achieve the necessary fluidity.

The Need for Specialized Equipment

Because of the risks, using general-purpose heating equipment is not advisable. Investing in a dedicated honey heating tank or warmer with accurate thermostatic controls is crucial for protecting your product and your investment.

Energy and Time Considerations

Heating an entire tank of honey requires both energy and time. This must be factored into the operational cost and workflow of any beekeeping or honey-packing business.

Making the Right Choice for Your Goal

- If your primary focus is efficiency: Gentle, controlled heating is the most effective way to accelerate your filtering and bottling workflow.

- If your primary focus is preserving raw honey quality: Use the lowest effective temperature required to liquify crystals, ensuring you do not damage the natural enzymes and delicate flavors.

- If your primary focus is operational consistency: Investing in equipment with precise temperature control is the only way to guarantee a uniform product and prevent costly batch losses from scorching.

Ultimately, using heat wisely is about transforming a difficult, viscous product into a manageable one without sacrificing its quality.

Summary Table:

| Goal | Recommended Heating Approach | Key Benefit |

|---|---|---|

| Improve Efficiency | Gentle, controlled heating | Accelerates filtering and bottling workflow |

| Preserve Raw Quality | Use lowest effective temperature | Protects natural enzymes and delicate flavors |

| Ensure Consistency | Invest in precision temperature equipment | Guarantees uniform product and prevents batch loss |

Ready to optimize your honey processing with precision heating?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-focused honey heating tanks and processing equipment. Our solutions provide the precise temperature control you need to reduce viscosity for efficient pumping and bottling, while critically preserving your honey's natural quality.

Contact HONESTBEE today to discuss how our equipment can enhance your operation's efficiency and protect your product.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

People Also Ask

- How to use honey that has hardened? Safely Restore Its Liquid Form with Gentle Heat

- Why is precise temperature control critical for honey heating equipment? Protect HMF Levels and Enzyme Bioactivity

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- Why is a constant temperature water bath used when processing crystallized honey samples? Ensure Analytical Precision

- How can commercial beekeepers manage hive temperatures? Balance Heat Stress and Hive Defense Effectively

- Why is heating equipment used to heat honey samples to 50°C? Mastering Pretreatment for Honey Crystallization Analysis

- Why is industrial-grade constant temperature heating equipment essential for the detoxification processing of specialty honey? Ensure Consumer Safety

- Why is a polystyrene foam insulation box used with beehive heating? Optimize Your Colony's Thermal Energy Efficiency