At its core, an automated honey filling machine's feeding system moves honey from a large storage container, called a hopper, to the filling mechanism that dispenses it into jars. This transfer is typically accomplished using one of two primary methods: a simple gravity feed or a more active pump system, which ensures a continuous supply for the filling process.

The central challenge in any honey feeding system is managing the honey's high viscosity, or thickness. The choice between a gravity, pump, or integrated piston system is therefore a critical decision driven by the need to balance production speed, filling accuracy, and the specific properties of the honey.

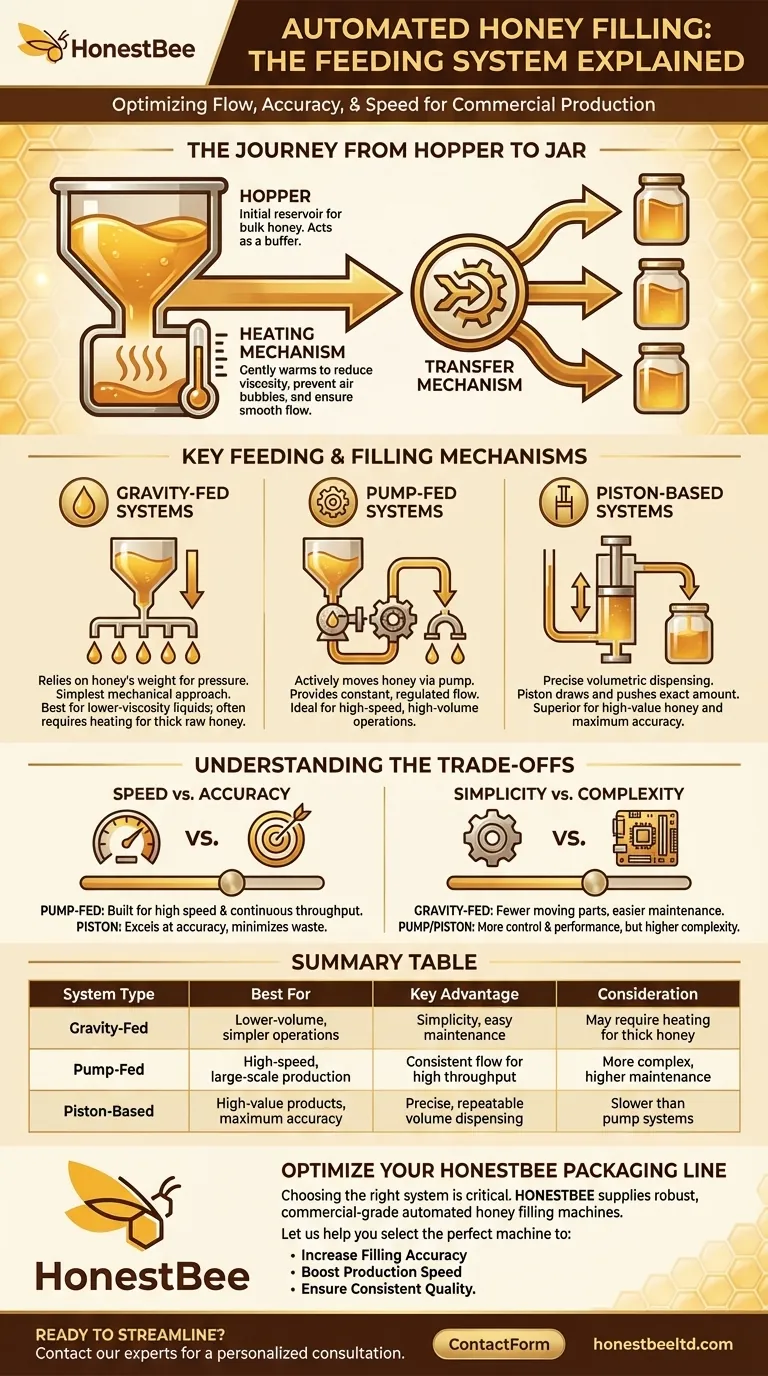

The Journey from Hopper to Jar

A honey filling machine operates through a sequence of integrated stages. The feeding system is the crucial first step that dictates the efficiency of the entire process.

The Storage Hopper

The hopper is the initial reservoir that holds the bulk honey before it enters the filling lines. It acts as a buffer, ensuring the machine has a consistent and ready supply.

Many advanced systems integrate a heating mechanism within the hopper. By gently warming the honey, its viscosity is reduced, allowing it to flow more smoothly and preventing the introduction of air bubbles during filling.

The Transfer Mechanism

This is the system that actively moves the honey from the hopper to the point of dispensing. The design of this mechanism is directly tied to the filling technology used by the machine.

Key Feeding and Filling Mechanisms Explained

The method used to feed and dispense honey is the most critical technical choice, directly impacting the machine's performance with a viscous product like honey.

Gravity-Fed Systems

In a gravity-fed system, the hopper is positioned above the filling nozzles. The machine relies on the weight of the honey itself to create the pressure needed to fill the containers below.

This is the simplest mechanical approach. However, it works best with lower-viscosity liquids and may require a heating system to be effective with thicker, raw honey.

Pump-Fed Systems

These systems use a pump to actively and consistently move honey from the hopper through the filling lines to the nozzles. This provides a constant, regulated flow that is not dependent on the honey's weight or level in the hopper.

Pump-based systems are ideal for high-speed and high-volume operations, as they can maintain a consistent flow rate to keep up with a fast-moving production line.

Piston-Based Systems

A piston filler is a highly precise mechanism often favored for thick products like honey. In this integrated system, a piston retracts within a cylinder, creating a vacuum that draws a precise volume of honey directly from the hopper or feed line.

The piston then pushes forward, dispensing that exact amount of honey into the container. The volume is easily and accurately adjusted by changing the length of the piston's stroke.

Understanding the Trade-offs

Choosing the right system requires acknowledging the inherent compromises between different engineering approaches. There is no single "best" solution for every scenario.

Speed vs. Accuracy

Pump-fed systems are built for speed and continuous throughput, making them ideal for large-scale commercial packaging.

Piston fillers, on the other hand, excel at accuracy. Their ability to dispense a precise, repeatable volume makes them the superior choice for high-value honey where minimizing product waste is paramount.

The Viscosity Challenge

Thick, raw, or crystallized honey poses a significant challenge for any automated system. A simple gravity filler may struggle, leading to slow and inconsistent fills.

This is why heating systems are a common feature. By lowering the viscosity, they make both pump and piston systems operate more efficiently and ensure a clean, professional-looking fill without trapped air.

Simplicity vs. Complexity

A gravity-fed machine has fewer moving parts, making it simpler to operate, clean, and maintain.

Pump and piston systems are more mechanically complex. While offering greater control and performance, they require more sophisticated operation and have higher maintenance requirements.

Selecting the Right System for Your Operation

Your production goals should be the primary guide in selecting a machine.

- If your primary focus is maximum accuracy for a high-value product: A piston filler is the definitive choice for its precise, volumetric dispensing.

- If your primary focus is high-speed, large-scale production: A pump-fed system is engineered to deliver the consistent flow rate required for high throughput.

- If your primary focus is simplicity and lower-volume bottling: A gravity-fed system, especially when paired with a heating element, can be a cost-effective and reliable solution.

Understanding these core principles empowers you to choose a system that ensures both exceptional product quality and operational efficiency.

Summary Table:

| System Type | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Gravity-Fed | Lower-volume, simpler operations | Simplicity, easy maintenance | May require heating for thick honey |

| Pump-Fed | High-speed, large-scale production | Consistent flow for high throughput | More complex, higher maintenance |

| Piston-Based | High-value products, maximum accuracy | Precise, repeatable volume dispensing | Slower than pump systems |

Optimize Your Honey Packaging Line with HONESTBEE

Choosing the right feeding system is critical for your bottling efficiency and product quality. Whether you're a commercial apiary focused on high-volume production or a distributor needing reliable equipment, the wrong system can lead to wasted product and downtime.

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. We provide robust, commercial-grade automated honey filling machines designed to handle the unique challenges of honey's viscosity.

Let us help you select the perfect machine to:

- Increase Filling Accuracy and reduce product giveaway with precise piston systems.

- Boost Production Speed with high-flow pump systems for large batches.

- Ensure Consistent Quality with integrated heating options for a smooth, bubble-free fill.

Ready to streamline your packaging process? Contact our experts today for a personalized consultation and discover how our equipment can enhance your operation's profitability.

Visual Guide

Related Products

- Manual Honey Filling Machine Bottling Machine for Honey

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- Why are automated filling and sealing machines critical? Scale Your Honey Business for Global Retail and Export Success

- What are the advantages of using automated honey filling machines? Boost Precision & Hygiene in Your Apiary

- How do automated honey filling machines improve efficiency? Scale Your Production with Precision and Speed

- What is the function of bottling equipment in honey processing? Ensure Quality and Commercial Precision

- Why is choosing the right honey packaging machine important? Ensure Quality & Efficiency for Your Honey Business

- What process advantages do professional honey filtering and filling machines provide? Optimize Your Organic Honey Output

- How do industrial-grade beehive manufacturing and honey-filling machinery convert ecological value? | HONESTBEE

- How do industrial honey filling machines assist producers in remaining competitive? Beat Imports with Precision