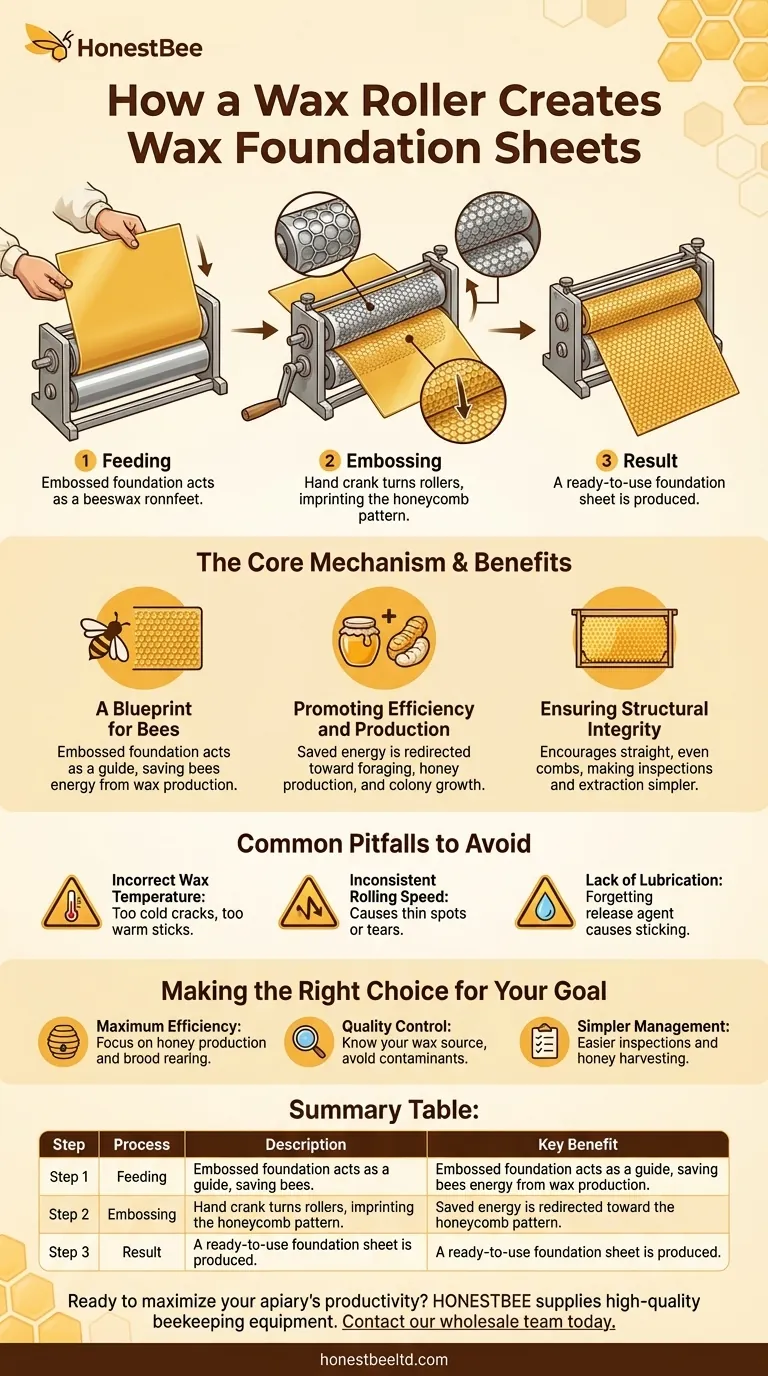

A wax roller works by manually pressing a plain sheet of beeswax between two engraved horizontal rollers. These rollers have a precise honeycomb hexagonal cell design on their surface. As the sheet passes through, the pressure embosses this pattern directly onto the wax, transforming a simple sheet into a ready-to-use foundation for a beehive.

The essential purpose of a wax roller is not simply to pattern the wax. It is to create a uniform, high-quality guide that directs the bees' natural comb-building instincts, saving them critical energy and dramatically increasing the hive's overall productivity.

The Core Mechanism: From Plain Sheet to Perfect Foundation

To understand the value of a wax roller, you must first understand its simple yet highly effective mechanical process. It's a tool designed to work in harmony with the bees' biology.

The Engraved Rollers

At the heart of the machine are two horizontal rollers. Each roller's surface is meticulously engraved with the negative of a honeycomb pattern, featuring the classic hexagonal cell bases.

The Embossing Process

A beekeeper feeds a smooth, plain sheet of beeswax between these two rollers. By turning a hand crank, the sheet is drawn through. The pressure exerted by the rollers imprints the hexagonal pattern onto both sides of the wax sheet.

The Resulting Uniformity

This manual process creates foundation sheets with a consistent and uniform cell size. This uniformity is a key advantage over naturally drawn comb, which can be irregular.

Why This Foundation is Critical for a Hive

Creating a foundation sheet is about giving the colony a significant head start. Bees must expend a large amount of energy to produce wax, and this tool helps them use their resources for other vital tasks.

A Blueprint for Bees

The embossed foundation acts as a blueprint or a guide. The bees immediately recognize the pattern and begin to "draw out" the cells, building up the walls to create the complete honeycomb structure for storing honey and raising brood.

Promoting Efficiency and Production

By providing this base, you save the bees the enormous energy cost of producing the initial wax and structuring the comb from scratch. This saved energy is redirected toward foraging, honey production, and colony growth, leading to a healthier and more efficient hive.

Ensuring Structural Integrity

A proper foundation encourages bees to build straight, even combs within the provided frames. This makes hive inspections and honey extraction far simpler and less disruptive for the beekeeper.

Common Pitfalls to Avoid

While the process is straightforward, the quality of the final product depends on attention to detail. Ignoring these factors can lead to brittle foundation or poor acceptance by the bees.

Incorrect Wax Temperature

The beeswax sheet must be at the right temperature before rolling. If the wax is too cold, it will be brittle and may crack under pressure. If it is too warm, it can stick to the rollers and lose the pattern's definition.

Inconsistent Rolling Speed

Turning the crank too quickly or with jerky motions can cause thin spots or tears in the foundation sheet. A slow, steady pressure is required to ensure a deep and uniform embossment.

Lack of Lubrication

The rollers often require a release agent, typically a soapy water solution, to prevent the beeswax from sticking. Forgetting this step can damage the foundation sheet and make the process frustrating.

Making the Right Choice for Your Goal

Using a wax roller is a strategic decision that impacts how you manage your apiary. Your specific goals will determine how you value this process.

- If your primary focus is maximum hive efficiency: Using a roller to create uniform foundation gives your bees a crucial head start, channeling their energy directly into honey production and brood rearing.

- If your primary focus is quality control: Producing your own foundation sheets ensures you know exactly what is in your wax, helping you avoid potential contaminants from unknown sources.

- If your primary focus is simpler hive management: The straight, predictable combs built on these foundations make hive inspections and honey harvesting significantly easier and less disruptive to the colony.

Ultimately, mastering this tool empowers you to provide your colony with the ideal structure for productivity and health.

Summary Table:

| Step | Process | Key Benefit |

|---|---|---|

| 1. Feeding | Plain beeswax sheet is fed between two engraved rollers. | Provides a base for the embossing process. |

| 2. Embossing | Hand crank turns rollers, imprinting the honeycomb pattern. | Creates a uniform, hexagonal cell guide for the bees. |

| 3. Result | A ready-to-use foundation sheet is produced. | Saves bees energy, promotes straight comb, and boosts hive efficiency. |

Ready to maximize your apiary's productivity? HONESTBEE supplies high-quality beekeeping equipment, including durable wax rollers and foundation supplies, to commercial apiaries and distributors. Let us help you equip your operation for superior hive health and honey production. Contact our wholesale team today to discuss your needs!

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets