At its core, using wire mesh in a beehive helps control varroa mites through a simple physical principle. When mites naturally fall off their bee hosts, the mesh floor allows them to drop completely out of the hive. Unable to climb back through the screen, these mites are permanently removed from the colony, which helps to reduce the overall mite population.

A screened bottom board is not a standalone treatment for a varroa infestation, but rather a crucial piece of passive infrastructure. It works by constantly reducing the mite population and provides a vital tool for monitoring the level of infestation within the hive.

The Mechanics of Mite Control with Mesh

To understand the value of wire mesh, often called a screened bottom board, we must first look at the behavior of the varroa mite itself.

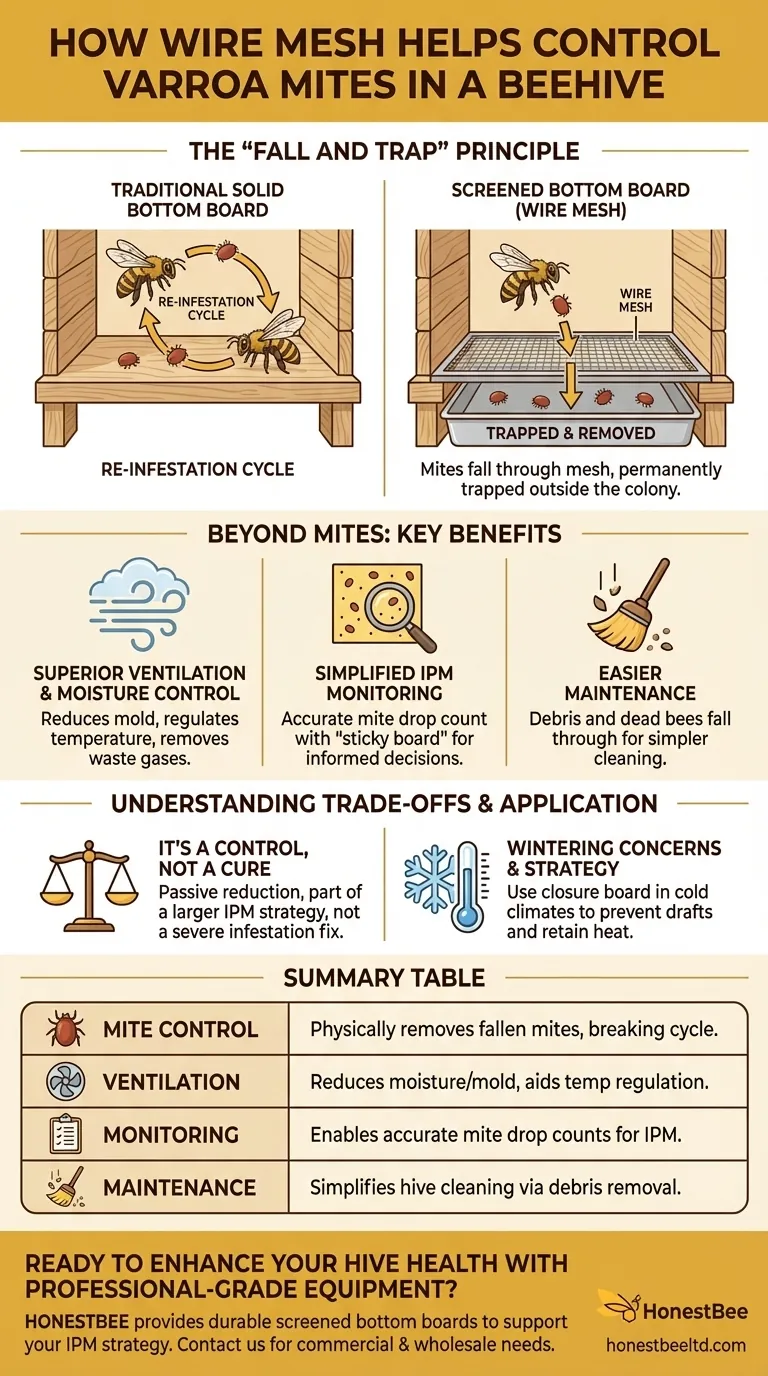

The "Fall and Trap" Principle

Varroa mites spend a portion of their lives on adult bees. During grooming or other activity, some of these mites lose their grip and fall to the bottom of the hive.

On a traditional solid bottom board, these mites can simply wait for a passing bee to climb back onto, re-entering the parasitic cycle.

Breaking the Re-infestation Cycle

A screened bottom board fundamentally disrupts this process. The mesh is sized to be too small for bees to pass through but large enough for mites to fall through.

Once a mite falls through the screen, it is trapped and cannot return to the hive. This constant, passive removal of mites lowers the reproductive pressure on the colony.

Beyond Mites: Key Benefits for Overall Hive Health

While varroa control is a major advantage, screened bottom boards contribute to a healthier hive environment in several other critical ways.

Superior Ventilation and Moisture Control

The open mesh provides excellent airflow throughout the hive. This ventilation is crucial for reducing moisture buildup, which in turn prevents the growth of mold and mildew.

Proper airflow also helps the bees regulate the hive's internal temperature more efficiently, dissipating excess heat in the summer and removing waste gases like carbon dioxide.

Simplified Hive Monitoring and Maintenance

A screened bottom board is an essential tool for Integrated Pest Management (IPM). By sliding a white, sticky board (often called a "sticky board") underneath the screen for 24-72 hours, a beekeeper can perform a "mite drop count."

This count gives you an accurate estimate of the infestation level within the hive, allowing you to make an informed decision about whether more aggressive treatments are necessary. Debris and dead bees also fall through, simplifying general cleaning.

Understanding the Trade-offs

While highly effective, a screened bottom board is a tool that must be managed correctly. It is not a complete solution on its own.

It's a Control, Not a Cure

A screened bottom board reduces the mite population but will not eliminate a severe infestation. It is a passive control method that should be part of a larger IPM strategy, which may include other treatments when mite counts get too high.

Potential Wintering Concerns

In colder climates, the increased airflow from an open screen can create a draft, making it harder for the bee cluster to stay warm.

For this reason, many beekeepers slide a closure board or the sticky board into place under the screen during the coldest months to reduce airflow and improve insulation.

How to Apply This to Your Apiary

Using a screened bottom board is a strategic decision based on your management style and climate.

- If your primary focus is passive mite reduction: A screened bottom board is one of the best "set and forget" tools for constantly lowering the background mite population with zero chemical input.

- If your primary focus is practicing IPM: The true power of a screened bottom board is its use with a sticky board to accurately monitor mite levels, guiding your treatment decisions.

- If your primary focus is overwintering in a cold climate: Use a screened bottom board for ventilation in the spring and summer, but be prepared to close it off during winter to protect the colony from drafts.

Ultimately, integrating a screened bottom board into your hive management empowers you with better data and provides a healthier, drier environment for your bees.

Summary Table:

| Function | Key Benefit |

|---|---|

| Mite Control | Physically removes fallen mites, breaking the re-infestation cycle. |

| Ventilation | Reduces moisture and mold, aids in temperature regulation. |

| Monitoring | Enables accurate mite drop counts for Integrated Pest Management (IPM). |

| Maintenance | Simplifies hive cleaning by allowing debris to fall through. |

Ready to enhance your hive health with professional-grade equipment?

As a wholesale supplier to commercial apiaries and distributors, HONESTBEE provides durable, effective screened bottom boards and other essential beekeeping supplies. Our equipment is designed to support your IPM strategy, improve colony vitality, and streamline your operations.

Contact HONESTBEE today to discuss your commercial or wholesale needs and discover how our solutions can contribute to the success of your apiary.

Visual Guide

Related Products

- Reusable Clear Small Hive Beetle Traps for Beehives Beetle Trapping Tools

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

- Gourd Shaped Hanging Wasp Trap Professional Wasp Catcher

- Removable Washable Hive Beetle Trap Attractants for Small Hive Beetles

- Solid Bottom Board Australian Pine Wood Langstroth Bottom Board for Wholesale

People Also Ask

- Why are hive beetle traps important for beekeepers? Protect Your Hive from a Devastating Infestation

- What role do internal beetle traps play in monitoring hive infestations? Precise Diagnostics for Apiary Health

- How do Beetle Blasters trap adult beetles? A Simple, Non-Chemical Pest Control Solution

- Why is standardized hive management critical for SHB control? Strengthen Your Apiary Against Small Hive Beetle

- What is the recommended number of beetle traps per hive? Optimize Your Hive's Beetle Defense