While you can technically decrystallize honey an unlimited number of times, it is not a consequence-free process. Each cycle of heating and cooling permanently degrades the honey's quality. The practical limit is therefore a question of how much of its original character—its unique flavor, aroma, and nutritional profile—you are willing to sacrifice for a liquid consistency.

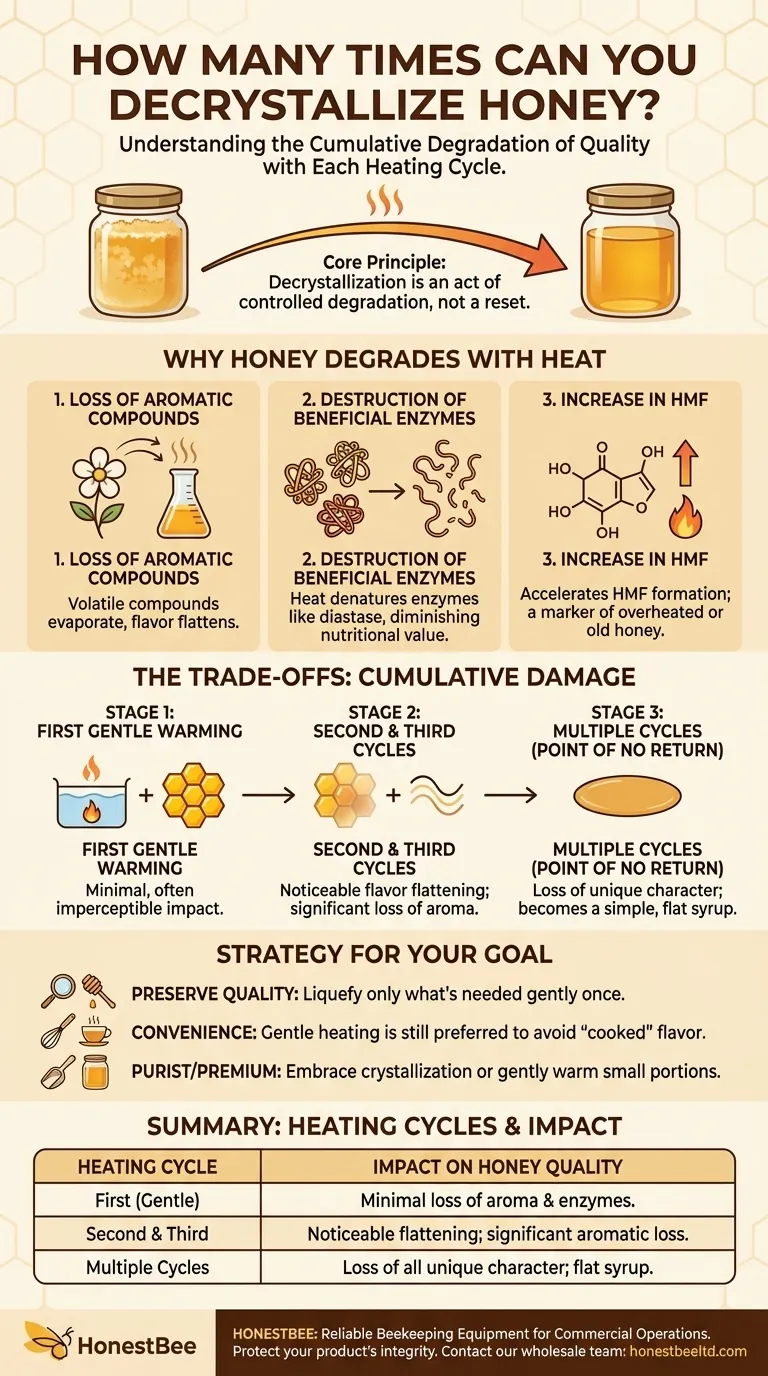

The core principle to understand is that decrystallization is not a reset button; it is an act of controlled degradation. Each time you apply heat, you are trading a portion of the honey's delicate complexity for the convenience of a liquid state.

Understanding the "Why" Behind the Warning

To manage your honey effectively, it's crucial to understand why this degradation occurs. Honey isn't just sugar and water; it's a complex biological substance.

Crystallization is a Natural and Reversible Process

Honey is a supersaturated solution, containing more sugar (primarily glucose and fructose) than can theoretically remain dissolved in its water content. Over time, the less-soluble glucose molecules begin to precipitate out of the solution, forming the solid crystals you see.

This is a natural process and a sign of pure, unprocessed honey. It is not an indication that the honey has spoiled.

Heat Irreversibly Degrades Honey's Quality

When you heat honey, you are doing more than just melting sugar crystals. You are fundamentally altering its chemical composition in three key ways.

1. Loss of Aromatic Compounds The unique and delicate flavors and aromas of a specific honey varietal come from volatile organic compounds derived from its original nectar source. Heat causes these compounds to evaporate, much like the scent of brewing coffee fades over time. With each heating cycle, more of this aromatic signature is lost, leaving the honey with a flatter, more one-dimensional sugary taste.

2. Destruction of Beneficial Enzymes Raw or minimally processed honey contains natural enzymes, such as diastase and invertase, which are introduced by bees. These enzymes are proteins that are sensitive to heat. Exposing honey to high temperatures permanently denatures them, diminishing its unique nutritional properties.

3. Increase in HMF Heating honey also accelerates the formation of a compound called Hydroxymethylfurfural (HMF). While HMF occurs naturally in honey in tiny amounts, high levels indicate excessive heat exposure or old age. It is a key quality marker used by food regulators to identify overheated or adulterated honey.

Understanding the Trade-offs: Each Cycle is a Compromise

Not all heating is equal, but the damage is cumulative. The goal is to minimize this damage by applying the least amount of heat, as infrequently as possible.

The First Gentle Warming

A single, carefully controlled decrystallization using a low-temperature water bath will have a minimal and often imperceptible impact on the honey's quality. This is the most acceptable approach.

Subsequent Heating Cycles

Each subsequent cycle compounds the damage. The honey will become progressively less aromatic and flavorful. After two or three cycles, even an untrained palate will likely notice a significant difference compared to the original product.

The Point of No Return

Eventually, the honey will lose all of its unique floral notes and character. It will still be a sweet syrup, but it will lack the complexity and nuance that defines high-quality honey.

How to Apply This to Your Goal

Your strategy for dealing with crystallized honey should align directly with your intended use and how much you value its original character.

- If your primary focus is preserving the full flavor and nutritional value: Decrystallize honey only once using a gentle water bath and, most importantly, liquefy only the amount you plan to use in the near future.

- If your primary focus is convenience for use in baking or sweetening tea: The degradation of nuanced flavors is less critical, as the cooking or brewing process will alter them anyway. However, gentle heating is still preferred to avoid a "cooked" flavor.

- If you are a honey purist or managing a premium product: It is best to embrace crystallization as a natural state or scoop out and gently warm small portions as needed, leaving the master batch untouched.

By treating heat as a tool to be used sparingly and with precision, you can manage crystallization while preserving the remarkable qualities of your honey.

Summary Table:

| Heating Cycle | Impact on Honey Quality |

|---|---|

| First (Gentle) | Minimal, often imperceptible loss of aroma and enzymes. |

| Second & Third | Noticeable flattening of flavor; significant loss of aromatic compounds. |

| Multiple Cycles | Loss of all unique character; honey becomes a simple, flat syrup. |

For commercial apiaries and distributors, honey quality is your reputation.

Each time you need to decrystallize a batch, you risk degrading the very qualities that make your honey valuable. The right equipment is key to minimizing this damage.

HONESTBEE supplies durable, reliable beekeeping equipment designed for commercial-scale operations. From precise warming cabinets to efficient storage solutions, our products help you protect your product's integrity from hive to market.

Protect your product's quality and your brand's reputation. Contact our wholesale team today to discuss equipment solutions for your apiary.

Visual Guide

Related Products

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- HONESTBEE Commercial Upright Honey Melter

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What features are common in insulated heat blankets for honey barrels? Essential Gear for Nutrient Preservation

- What is the function of a heating system for beehives? Accelerate Colony Growth with Ceramic Heat Regulation

- How does specialized heating equipment contribute to the mechanical control of Varroa mites? Protect Brood Safely

- How do you use a honey warmer? A Guide to Safe, Gentle Honey Decrystallization

- Why is heating honey sometimes necessary? The Essential Guide to Processing & Quality

- Why is heating equipment necessary when preparing a 50% sugar syrup for bee feeding? Improve Stability and Bioavailability

- What are the efficiency benefits of using a honey heating tank? Boost Processing Speed & Protect Honey Quality

- Why is a precision constant temperature drying oven set to 30°C used for bee pollen? Optimize Sample Integrity