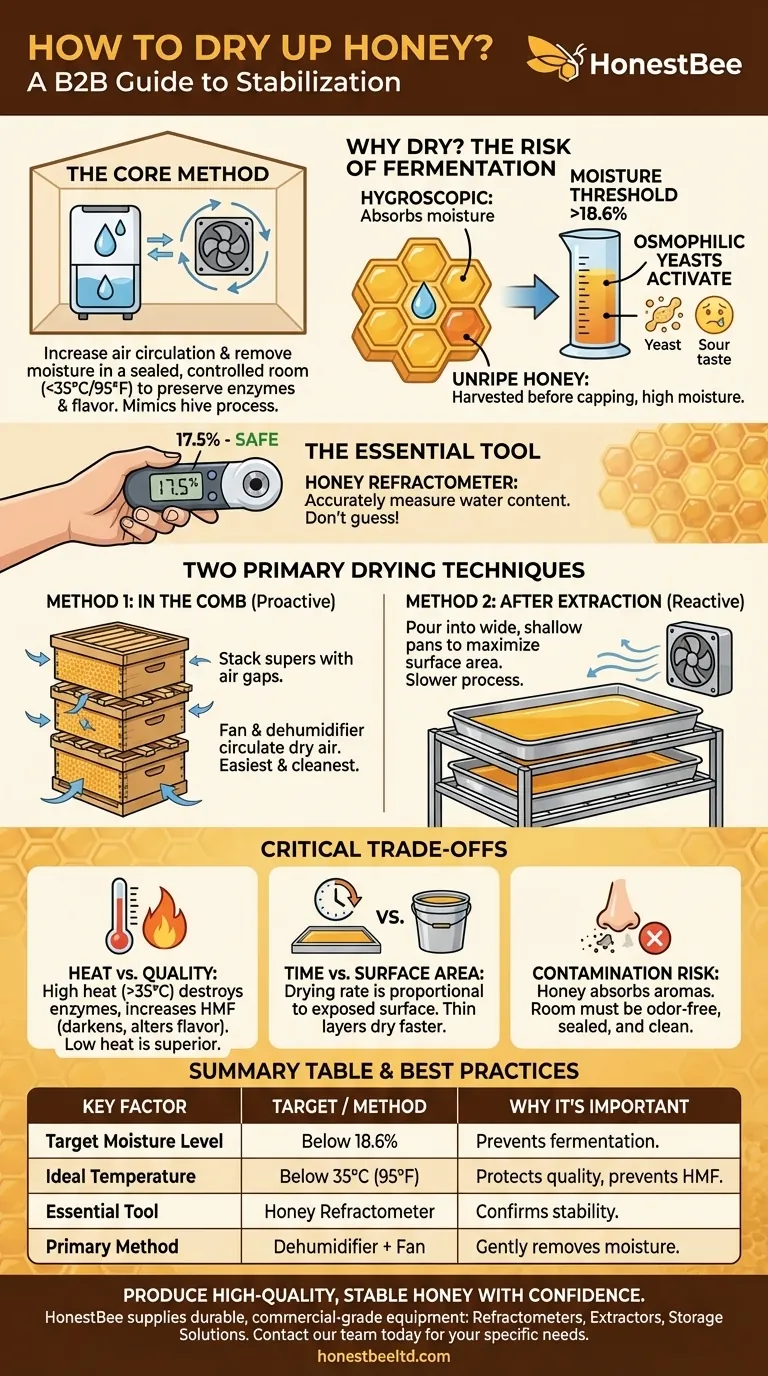

To dry honey, the most effective method is to increase air circulation over its surface while using a dehumidifier to remove moisture from the air. This process should be done in a small, sealed room at a controlled temperature, ideally below 35°C (95°F), to avoid damaging the honey's delicate enzymes and flavor. This can be done either with the honey still in the comb before extraction or with extracted honey poured into shallow pans.

The core challenge is not simply removing water, but doing so gently. High heat will ruin honey's quality. The key to successful drying lies in maximizing the honey's surface area and using a dehumidifier to create a dry environment, mimicking the process bees use inside the hive.

Why Honey Needs Drying: The Risk of Fermentation

The Critical Moisture Threshold

Honey is hygroscopic, meaning it can absorb moisture from the air. For honey to be stable for long-term storage, its water content must be below approximately 18.6%.

When the moisture level rises above this point, dormant, naturally occurring osmophilic yeasts can activate and begin to ferment the sugars in the honey. This results in a sour taste, a "bubbly" appearance, and spoilage.

What is "Unripe" Honey?

Bees create honey by collecting nectar and dehydrating it. They fan their wings over the nectar stored in honeycomb cells to create airflow, slowly reducing its water content. Once the honey reaches the right moisture level, the bees seal the cell with a wax capping.

"Unripe" or "green" honey is honey that is harvested before the bees have had a chance to cap it. Its moisture content is often too high, putting it at immediate risk of fermentation.

The Essential Tool: A Honey Refractometer

You cannot manage what you do not measure. A honey refractometer is a simple, essential handheld tool that allows you to instantly and accurately measure the percentage of water in your honey.

Using a refractometer before and during the drying process is the only way to know for sure when your honey has reached a safe, stable moisture level.

The Two Primary Drying Methods

Method 1: Drying in the Comb (The Proactive Approach)

Drying honey while it's still in the frames is often the easiest and cleanest method. The honeycomb itself acts as a perfect container that already has a massive surface area.

To do this, stack your honey supers in a small, clean, and sealable room. Place small wood blocks or spacers between each super to create an air gap, allowing air to flow across the faces of the frames. Run a dehumidifier and a small fan in the room to circulate dry air throughout the stacks.

Method 2: Drying After Extraction (The Reactive Approach)

If you have already extracted honey with high moisture content, you can still dry it. The principle is the same: maximize surface area.

Pour the honey into wide, shallow, food-safe containers, such as stainless steel steam table pans. The honey layer should be as thin as possible. Place these pans in your sealed room with a dehumidifier and fan. This method is generally slower than drying in the comb.

Understanding the Critical Trade-offs

Heat is the Enemy of Quality

Gently warming the drying room to a "hive temperature" of around 30-35°C (85-95°F) can speed up the process. However, exceeding this temperature is highly destructive.

High heat degrades the beneficial enzymes in honey and dramatically increases the levels of Hydroxymethylfurfural (HMF), a compound that indicates heat damage and age. This darkens the honey, alters its flavor, and lowers its quality. Low heat with good air movement is always the superior choice.

Time vs. Surface Area

The rate of drying is directly proportional to the amount of honey surface exposed to dry, moving air. A thin layer of honey in a wide pan will dry much faster than a deep bucket of honey.

Similarly, ensuring good airflow between your supers is critical when drying in the comb. Without it, only the top and bottom frames in the stack will dry effectively.

The Risk of Contamination and Off-Flavors

By its hygroscopic nature, honey will absorb not just water but also aromas from the air. Your drying room must be impeccably clean and free of any strong odors (onions, chemicals, etc.). Keep the room sealed to prevent dust or debris from settling on the exposed honey.

Making the Right Choice for Your Goal

A successful outcome depends on correctly matching the technique to your situation. Always use a refractometer to confirm your results.

- If your primary focus is efficiency and quality: Dry the honey in the comb before extracting using the stacked super method with a dehumidifier.

- If you have already extracted "wet" honey: Use wide, shallow pans to maximize surface area and place them in a clean, sealed room with a dehumidifier and fan.

- If your primary focus is preserving maximum quality: Keep drying temperatures below 35°C (95°F) and aim for a final moisture content between 17% and 18%.

By carefully controlling humidity and airflow, you can reliably stabilize your honey, ensuring it remains a pure, high-quality product for years to come.

Summary Table:

| Key Factor | Target / Method | Why It's Important |

|---|---|---|

| Target Moisture Level | Below 18.6% | Prevents fermentation by osmophilic yeasts. |

| Ideal Temperature | Below 35°C (95°F) | Protects delicate enzymes and flavor; prevents HMF increase. |

| Essential Tool | Honey Refractometer | Accurately measures water content to confirm stability. |

| Primary Method | Dehumidifier + Fan | Gently removes moisture by creating a dry, circulating air environment. |

Produce and Sell High-Quality, Stable Honey with Confidence

As a commercial apiary or beekeeping equipment distributor, the quality and shelf-life of your honey directly impact your reputation and profitability. Ensuring your honey is properly dried and stabilized is a critical step.

At HONESTBEE, we supply the durable, commercial-grade equipment you need to perfect this process. From honey refractometers for precise moisture measurement to the robust extractors and storage solutions that protect your product's integrity, our wholesale-focused operations are designed to support your business's scale and success.

Let's discuss your specific needs. Contact our team today to get the right equipment for producing consistently superior honey.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- 10L Stainless Steel Electric Honey Press Machine

- Professional Thermostatic Conical Honey Melter

People Also Ask

- How do you remove moisture from honey? Ensure Quality & Shelf-Stable Honey

- Why is convective drying equipment with dehumidification recommended for Bee Bread? Preserve Potency with Low Heat

- What role does professional honey dehydration equipment play in honey quality management? Control Moisture & Purity

- What is the technical significance of using a refrigerant dehumidifier in a honey dehydration system? Optimize Honey Quality

- What is the recommended operating temperature for drying honey? Preserve Quality and Enzymes with Precision Heating

- What role does a centrifugal fan play in a honey dehydration system? Ensure Efficient Moisture Removal Under 17%

- What temperature is used to process the honey in the dryer? Preserve Honey Quality with Precise Heat Control

- What is the drawback of the conventional honey drying method? It Compromises Honey Quality with High Heat