In short, no, spray release is not strictly necessary when using silicone molds for candle making. The inherent flexibility and non-stick nature of silicone are specifically why it is a preferred material; it is designed to release cleanly on its own. While not required, some makers use a release agent as a precautionary measure to guarantee a flawless result.

The core issue is not whether to use a release spray, but how to guarantee a perfect, damage-free candle every time. While spray is an optional tool, true success lies in understanding your mold, your wax, and your process.

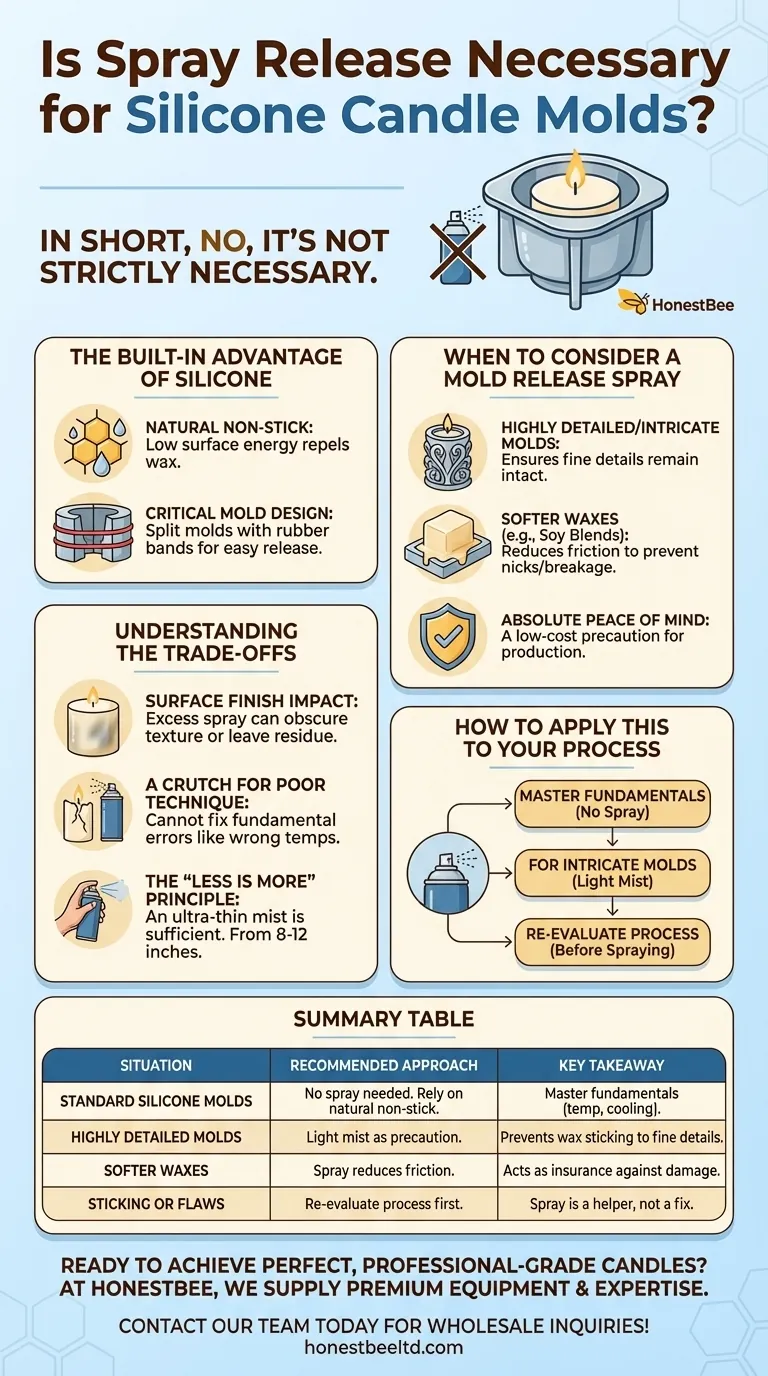

The Built-in Advantage of Silicone

Silicone molds have become the standard for pillar and decorative candles for a reason. Their physical properties are engineered to make the demolding process straightforward.

Natural Non-Stick Properties

Silicone has very low surface energy, which means other materials, like candle wax, have a difficult time adhering to it. This is the same principle that makes silicone baking mats and spatulas so effective.

The Critical Role of Mold Design

Most professional-grade silicone candle molds are not a single, solid piece. They feature a split down one side, which is the primary mechanism for easy release.

You secure the mold by wrapping it tightly with two or more strong rubber bands before pouring. Once the candle has fully hardened, you simply remove the bands, and the mold peels away from the candle with minimal effort.

When to Consider a Mold Release Spray

While not essential, a release spray can serve as a low-cost insurance policy in specific situations. Think of it as a helper, not a requirement.

For Highly Detailed or Intricate Molds

Molds with very fine details, deep undercuts, or complex textures have more surface area where wax can potentially get caught. A very light mist of spray can provide extra "slip" to ensure every detail remains intact on the candle.

With Softer Waxes

Some waxes, particularly certain soy or natural wax blends, remain softer even when fully cured. These can be more susceptible to nicks, scratches, or breakage during demolding. A release agent reduces the friction, minimizing the risk of damage.

For Absolute Peace of Mind

If you are producing candles for sale or simply want to maximize your success rate, a quick spray is a simple step that can prevent the occasional frustrating failure. It rarely causes harm and can often help.

Understanding the Trade-offs

Using a mold release is not without potential downsides. It is a tool that must be used correctly to be effective.

Potential Impact on Surface Finish

Applying too much release spray is the most common mistake. Excess spray can pool in the bottom or in the fine details of the mold, potentially obscuring the candle's surface texture or leaving a slightly oily residue.

A Crutch for Poor Technique

Mold release cannot fix fundamental process errors. If your candle sticks or breaks, the root cause is more likely to be demolding too early or pouring the wax at the wrong temperature. Relying on spray can mask the real problem.

The "Less is More" Principle

If you choose to use a spray, the goal is an ultra-thin, nearly invisible coating. A single, quick mist from 8-12 inches away is more than sufficient.

How to Apply This to Your Process

Your approach should depend on your materials and your goal. Use these guidelines to determine the best path for your project.

- If your primary focus is learning the craft: Start without release spray. This forces you to master the core variables: proper mold security, correct pouring temperature, and complete cooling time.

- If you are working with an intricate, expensive mold: Use a very light mist of a silicone-safe mold release as a precaution to protect both your mold and your candle.

- If you consistently experience sticking or flaws: Before reaching for a spray, first re-evaluate your process. Ensure your candle is 100% cool and hardened, which can take up to 24 hours for large pillars.

Mastering the fundamentals of your process will always yield better and more consistent results than relying on any single product.

Summary Table:

| Situation | Recommended Approach | Key Takeaway |

|---|---|---|

| Standard Silicone Molds | No spray needed. Rely on mold's natural non-stick properties. | Master the fundamentals of pouring temperature and cooling time. |

| Highly Detailed/Intricate Molds | A light mist of spray can be used as a precaution. | Prevents wax from sticking to fine details, ensuring a perfect finish. |

| Using Softer Waxes (e.g., certain soy blends) | Spray can reduce friction and minimize damage during demolding. | Acts as an insurance policy for a flawless release. |

| Experiencing Sticking or Flaws | Re-evaluate process (cooling time, pouring temp) before using spray. | Spray is a helper, not a fix for poor technique. |

Ready to achieve perfect, professional-grade candles every time?

At HONESTBEE, we supply premium, wholesale-focused beekeeping supplies and equipment to commercial apiaries and distributors. Our expertise extends to the tools and knowledge that help artisans and businesses excel. Whether you're a commercial candlemaker or a distributor sourcing reliable equipment, we provide the quality and support you need to streamline your process and maximize your success.

Let's discuss how we can support your operation. Contact our team today for wholesale inquiries and expert guidance!

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What customization options are available with fully automatic wax foundation machines? Tailor Sheets for Any Hive Frame

- What is the economic value of using candle-making equipment and beeswax consumables? Maximize Your Apiary Profits

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control