Beyond the standard double boiler, the most effective alternative methods for melting beeswax involve using a slow cooker (crock pot) or a solar melter. These methods are favored because they provide gentle, indirect heat. This approach is critical for safely melting the wax without scorching it or creating a fire hazard, thereby preserving its natural color, scent, and beneficial properties.

The most important principle is not the specific device you use, but the method of heat application. All safe methods for melting beeswax rely on indirect, controlled heat to avoid its low flash point and prevent destroying its natural qualities.

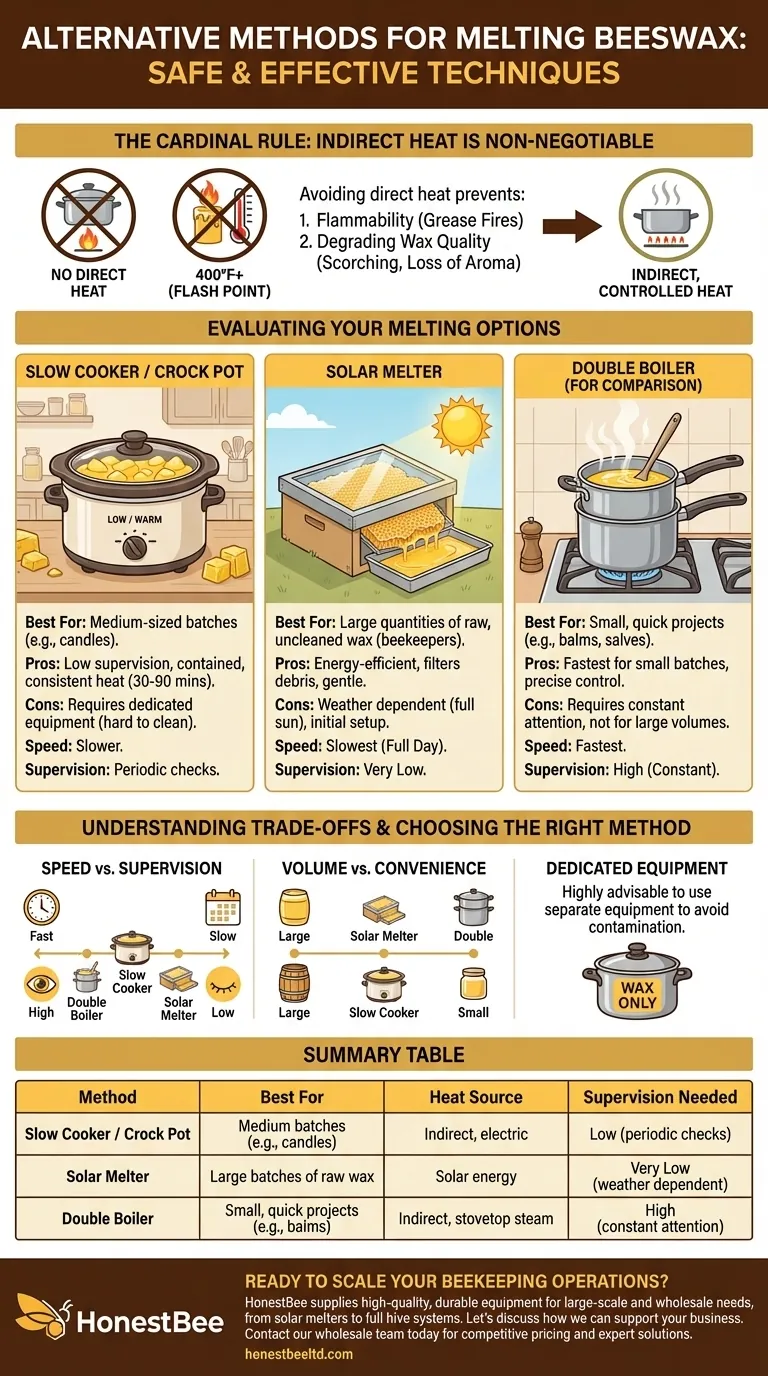

The Cardinal Rule: Why Indirect Heat is Non-Negotiable

Before choosing a tool, you must understand the two primary risks of melting beeswax. Both are solved by avoiding direct heat from a stovetop burner or open flame.

The Flammability Risk

Beeswax is a flammable material. When heated directly, it can easily surpass its flash point (around 400°F or 204°C) and ignite, creating a dangerous grease fire that cannot be extinguished with water. Indirect heating methods create a buffer that makes it nearly impossible to reach this temperature.

Preserving Wax Quality

Harsh, direct heat also damages the wax itself. To retain the natural antimicrobial properties and delicate aroma of beeswax, it should not be heated above 175°F (79°C). Overheating or scorching will darken the wax, give it a burnt smell, and degrade its quality.

Evaluating Your Melting Options

Each method offers a different balance of speed, volume, and convenience. The best choice depends entirely on the scale of your project.

The Slow Cooker / Crock Pot Method

This method uses a standard kitchen slow cooker set to its lowest temperature. It is an excellent, contained, and relatively hands-off approach for medium-sized batches.

Simply place your beeswax into the crock pot insert, set it to "Warm" or "Low," and let it melt slowly. Depending on the volume, this can take anywhere from 30 to 90 minutes. While convenient, you should never leave it completely unattended.

The Solar Melter Method

A solar melter is an insulated box with a glass or plastic top that uses the sun's energy to gently melt wax. This is the preferred method for beekeepers or anyone processing large quantities of raw, uncleaned wax.

The raw honeycomb is placed inside, and as the sun heats the box, the wax melts and filters through a screen or cloth, separating it from debris. It then collects in a tray below. This is the most energy-efficient and gentle method, but it is entirely dependent on clear, sunny weather.

The Double Boiler Method (For Comparison)

The classic double boiler works by placing a smaller pot containing the beeswax inside a larger pot of simmering water. The steam from the water provides even, indirect heat.

This remains the fastest method for small batches and offers excellent temperature control, but it requires your constant attention and is not practical for melting large volumes of wax.

Understanding the Trade-offs

Choosing a method requires balancing your needs for safety, speed, and scale. There is no single "best" way, only the most appropriate way for your task.

Speed vs. Supervision

The double boiler is the fastest method but demands the most active supervision. A slow cooker is significantly slower but requires only periodic check-ins. A solar melter is the slowest and most passive but requires initial setup and a full day of sun.

Volume vs. Convenience

A double boiler is ideal for the small volumes needed for a tube of lip balm or a single cosmetic formulation. A slow cooker is perfect for a batch of candles. A solar melter is built for processing pounds of raw cappings from a beehive.

The Dedicated Equipment Problem

Beeswax is notoriously difficult to clean from pots, bowls, and utensils once it hardens. It is highly advisable to acquire dedicated equipment for your wax projects—whether it's a cheap pot for a double boiler or a second-hand crock pot—to avoid contaminating your kitchenware.

Choosing the Right Method for Your Goal

Your project's specific needs should dictate your choice of equipment.

- If your primary focus is small, quick projects (like balms or salves): The double boiler offers the best combination of speed and precise control for small quantities.

- If your primary focus is convenient, medium-sized batches (like candles): A dedicated slow cooker or crock pot provides a safe, low-supervision solution.

- If your primary focus is processing large amounts of raw wax from a hive: A solar melter is the most economical and effective method for melting and clarifying wax simultaneously.

By prioritizing indirect heat and matching your method to your project's scale, you can melt beeswax safely and effectively every time.

Summary Table:

| Method | Best For | Heat Source | Supervision Needed |

|---|---|---|---|

| Slow Cooker / Crock Pot | Medium batches (e.g., candles) | Indirect, electric | Low (periodic checks) |

| Solar Melter | Large batches of raw wax | Solar energy | Very Low (weather dependent) |

| Double Boiler | Small, quick projects (e.g., balms) | Indirect, stovetop steam | High (constant attention) |

Ready to Scale Your Beekeeping Operations?

Melting wax safely is just one part of a successful apiary. For commercial beekeepers and equipment distributors, having a reliable wholesale partner is key to efficiency and growth.

HONESTBEE supplies high-quality, durable beekeeping supplies and equipment tailored for large-scale operations. From solar melters to full hive management systems, we provide the tools you need to succeed.

Let’s discuss how we can support your business. Contact our wholesale team today for competitive pricing and expert solutions.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish