At their core, gravity-fed volumetric filling systems provide a distinct set of advantages centered on simplicity, cost-effectiveness, and gentle product handling. They are engineered to use the natural force of gravity to dispense free-flowing, low-viscosity liquids from an overhead tank into containers, making them a highly reliable choice for specific applications.

The primary advantage of a gravity-fed volumetric filler is not universal superiority, but its exceptional efficiency and accuracy when handling the right type of product—namely, thin, non-carbonated liquids where consistent volume is critical.

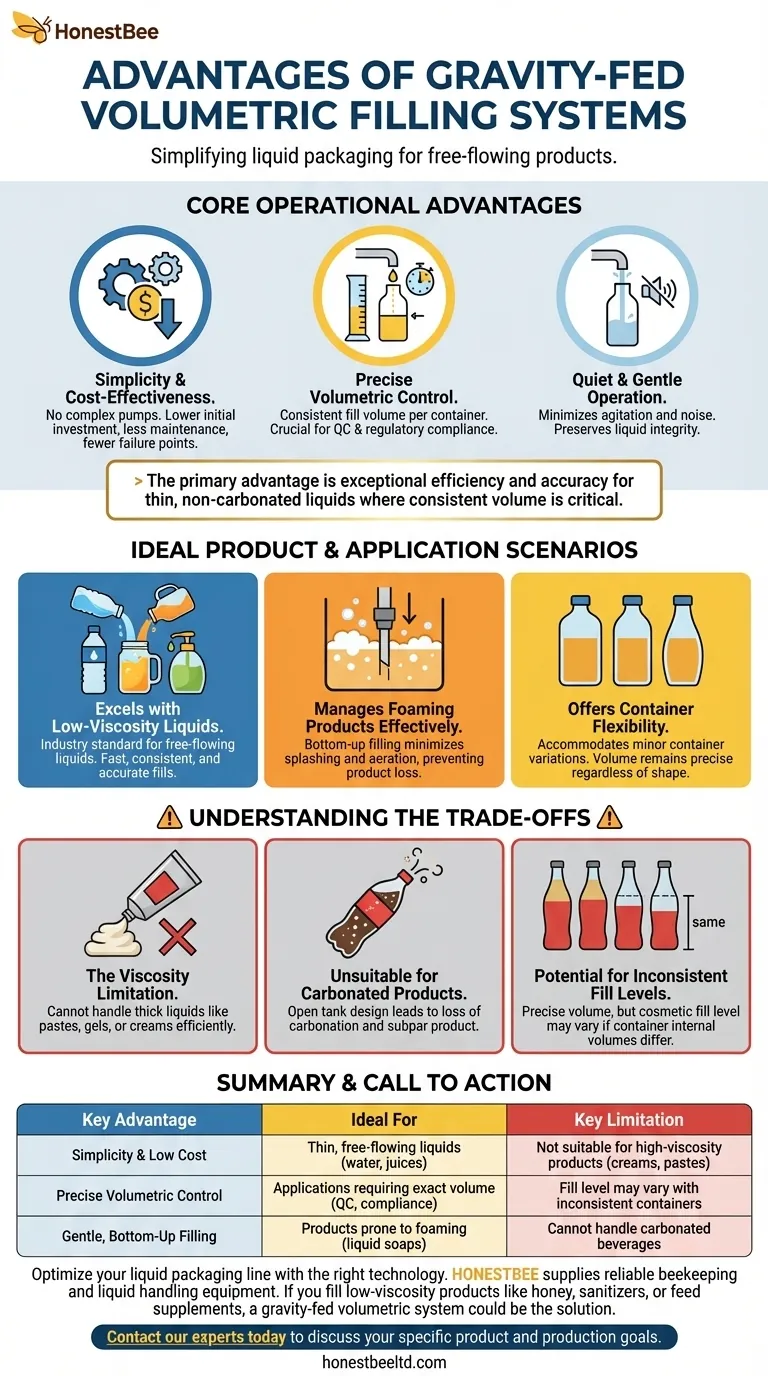

Core Operational Advantages

To understand if this system is right for your needs, it's essential to examine its fundamental operational benefits. These advantages stem directly from its simple and elegant design.

Simplicity and Cost-Effectiveness

Because the system relies on gravity, it eliminates the need for complex and expensive pumps or pressure systems. This reduced mechanical complexity translates directly into a lower initial investment, less maintenance, and fewer potential points of failure.

Precise Volumetric Control

The "volumetric" aspect is key. These machines fill containers based on a pre-set volume, typically controlled by the duration a valve remains open. This ensures that each container receives the exact same amount of product, a critical factor for quality control and regulatory compliance.

Quiet and Gentle Operation

The absence of high-pressure pumps makes the entire filling process remarkably quiet, contributing to a better work environment. The gentle, gravity-driven flow also minimizes agitation, preserving the integrity of the liquid being filled.

Ideal Product and Application Scenarios

The true value of a gravity-fed system emerges when it is matched with the appropriate product and container. Its design makes it uniquely suited for certain tasks.

Excels with Low-Viscosity Liquids

These systems are the industry standard for thin, free-flowing liquids. Products like water, juices, liquid soaps, solvents, and non-pulpy sauces flow easily and consistently under gravity, allowing for fast and accurate fills.

Manages Foaming Products Effectively

Many gravity fillers are designed for bottom-up filling. The dispensing nozzle is lowered to the bottom of the container and retracts as the liquid level rises. This technique minimizes splashing and aeration, making it an excellent choice for products prone to foaming.

Offers Container Flexibility

Since the fill is determined by volume, not by filling to a specific level in the container, the system easily accommodates minor inconsistencies in container manufacturing. Slight variations in the internal shape or capacity of bottles will not affect the accuracy of the dispensed product volume.

Understanding the Trade-offs

No single technology is a universal solution. To make an informed decision, you must recognize the inherent limitations of a gravity-fed system.

The Viscosity Limitation

The most significant trade-off is viscosity. Gravity alone does not provide enough force to move thick liquids like creams, gels, or thick pastes at an efficient rate. For such products, a piston or pump filler is necessary.

Unsuitable for Carbonated Products

The open holding tank design is not pressurized. Attempting to fill carbonated beverages with this system would result in a significant loss of carbonation, leading to a flat, subpar product.

Potential for Inconsistent Fill Levels

While the volume is precise, the cosmetic fill level can vary if the containers themselves have inconsistent internal volumes. If a perfectly uniform appearance on the shelf is the primary goal, a level-filling system might be a better alternative.

Making the Right Choice for Your Goal

Your product's characteristics and production priorities will determine if this technology is the correct fit.

- If your primary focus is cost-effective filling of free-flowing liquids: A gravity-fed system is likely your most efficient and reliable choice.

- If your primary focus is handling foaming products like soaps or juices: The bottom-up filling capability of these systems makes them a superior option to prevent product loss.

- If your primary focus is filling high-viscosity products like pastes or creams: You must look at other technologies, such as piston or pump fillers, as gravity alone will not be sufficient.

Understanding these core principles ensures you select a filling system that aligns perfectly with your product's characteristics and production goals.

Summary Table:

| Key Advantage | Ideal For | Key Limitation |

|---|---|---|

| Simplicity & Low Cost | Thin, free-flowing liquids (water, juices) | Not suitable for high-viscosity products (creams, pastes) |

| Precise Volumetric Control | Applications requiring exact volume (QC, compliance) | Fill level may vary with inconsistent containers |

| Gentle, Bottom-Up Filling | Products prone to foaming (liquid soaps) | Cannot handle carbonated beverages |

Optimize your liquid packaging line with the right technology.

HONESTBEE supplies reliable beekeeping and liquid handling equipment to commercial apiaries and distributors. If you fill low-viscosity products like honey, sanitizers, or feed supplements, a gravity-fed volumetric system could be the efficient, cost-effective solution you need.

Contact our experts today to discuss your specific product and production goals. We'll help you select the perfect equipment to ensure accuracy, preserve product quality, and maximize your ROI.

Visual Guide

Related Products

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Commercial Rotary Honey Filling Machine for Production

- Automatic In-Line Round Bottle Labeling Machine

People Also Ask

- In what way does automated honey-filling equipment contribute to the standardization of honey production? | HONESTBEE

- Why use industrial honey filling equipment for GI certification? Ensure Compliance and Premium Market Value

- What are the technical advantages of using automatic honey-filling machines? Boost Efficiency and Product Purity

- How does a liquid filling machine work? A Guide to Precise & Efficient Liquid Packaging

- How does resource mapping of birch forest types influence selection of honey filling equipment? Optimize Your ROI

- What are the key characteristics of a honey stick filling machine? High-Precision Packaging Solutions

- How does industrial honey filling equipment ensure product safety? Secure Your Commercial Honey Production Purity

- What are the customization options available for honey filling machines? Tailor Your Equipment for Peak Efficiency