The primary benefits of a motorized honey extractor are a dramatic reduction in physical labor and a significant increase in processing speed. By replacing manual cranking with an electric motor, these machines streamline the extraction process, making them an essential tool for beekeepers managing multiple hives or processing large volumes of honey.

A motorized extractor is an investment in operational efficiency. It transforms honey extraction from a labor-intensive chore into a controlled, repeatable process, making it the standard for any beekeeper looking to scale beyond a small hobbyist level.

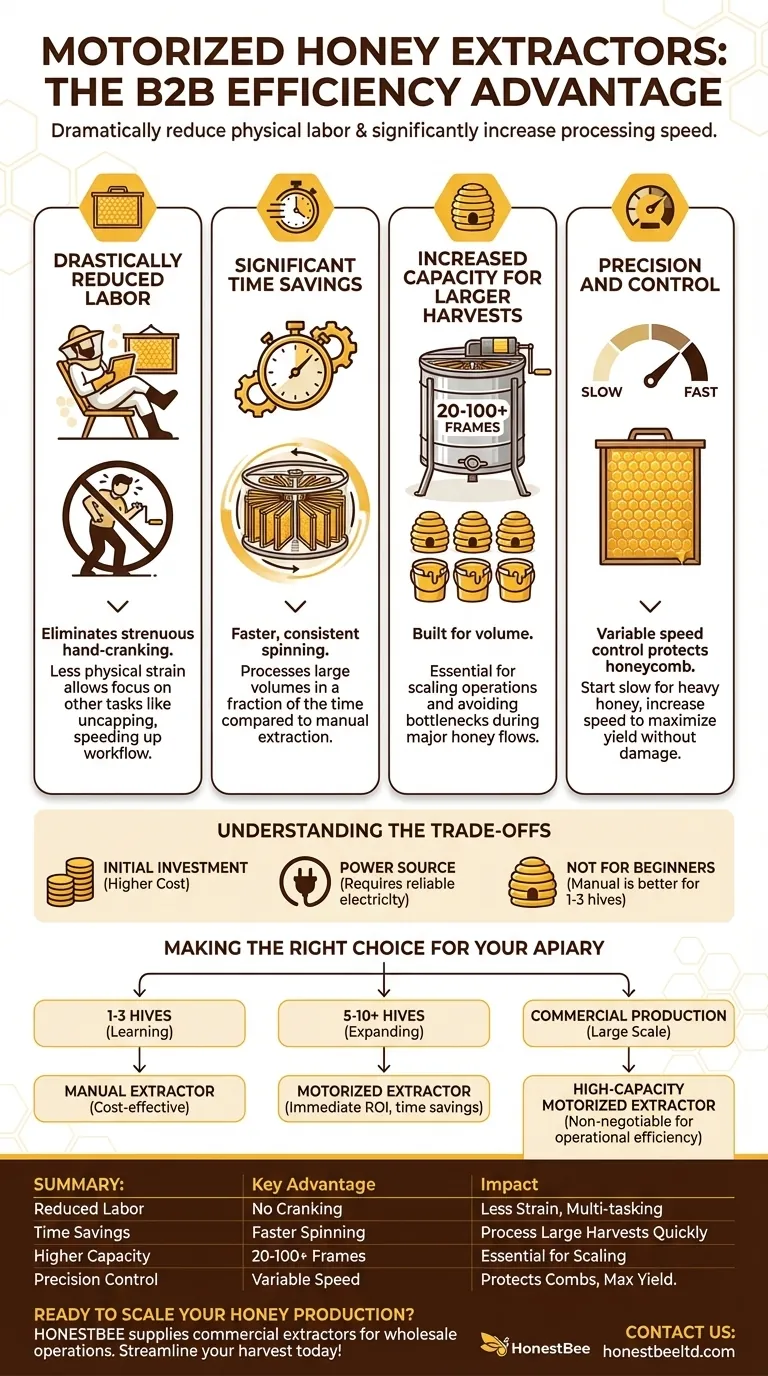

The Core Advantages of Motorization

Motorized extractors solve the two biggest challenges of honey harvesting: time and physical effort. The benefits are most apparent when compared to the manual alternative.

Drastically Reduced Labor

A motorized unit eliminates the need for continuous, strenuous hand-cranking. This is arguably its most significant benefit.

The reduction in physical strain allows a beekeeper to focus on other tasks, such as uncapping the next batch of frames, which further speeds up the entire workflow.

Significant Time Savings

Electric motors spin frames much faster and more consistently than is possible by hand.

This speed, combined with the ability to process many frames at once, means a harvest that could take hours with a manual extractor can often be completed in a fraction of the time.

Increased Capacity for Larger Harvests

Motorized extractors are built for volume. They are available in sizes that can hold anywhere from a few frames to over 100 frames for large commercial operations.

This high capacity is essential for beekeepers with a growing number of hives, ensuring the extraction process doesn't become a bottleneck during a major honey flow.

Precision and Control

Most motorized extractors offer variable speed control, a crucial feature for protecting your honeycomb.

You can start the spin slowly to extract the initial heavy honey without blowing out the delicate wax foundation. The speed can then be increased to efficiently remove the remaining honey, maximizing your yield while preserving the comb for the bees to reuse.

Understanding the Trade-offs

While the benefits are clear, a motorized extractor is not the default choice for every beekeeper. Objectivity requires acknowledging the downsides.

The Initial Investment

The most significant barrier is cost. Motorized extractors are considerably more expensive than their manual counterparts.

This initial expense must be weighed against the long-term savings in time and labor.

The Need for a Power Source

An electric extractor requires a reliable power source. This can be a challenge for beekeepers working in remote apiaries or off-grid locations.

While some models can be adapted for battery power, it's an additional logistical consideration.

The Alternative for Beginners

For those with only one or two hives, a manual tangential extractor is often a more practical starting point.

These smaller, less expensive units are gentler on combs but require you to manually flip each frame midway through the process, making them more labor-intensive and less suitable for larger harvests.

Making the Right Choice for Your Apiary

The decision to invest in a motorized extractor should be based on the current scale and future goals of your beekeeping operation.

- If your primary focus is learning with 1-3 hives: A manual extractor is a cost-effective and perfectly adequate tool for your needs.

- If your primary focus is expanding beyond 5-10 hives: A motorized extractor will provide an immediate and substantial return on investment through saved time and effort.

- If your primary focus is commercial production: A high-capacity, durable motorized extractor is a non-negotiable piece of equipment for achieving operational efficiency.

Ultimately, choosing the right extractor is about aligning your equipment with the scale and ambition of your beekeeping journey.

Summary Table:

| Benefit | Key Advantage | Impact on Beekeeping |

|---|---|---|

| Reduced Labor | Eliminates strenuous hand-cranking | Less physical strain, focus on other tasks |

| Time Savings | Faster, consistent spinning | Process large harvests in a fraction of the time |

| Higher Capacity | Holds 20-100+ frames | Essential for scaling beyond hobbyist level |

| Precision Control | Variable speed settings | Protects honeycomb, maximizes yield |

Ready to scale your honey production efficiently? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-capacity, durable motorized extractors designed for wholesale operations. Let us help you streamline your harvest and boost your output. Contact our team today to discuss the best extractor solution for your business!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- What factors should be considered when choosing between an electric and manual honey extractor?

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- Is the honey extractor better than the honey press? Choose the Right Tool for Your Apiary's Success