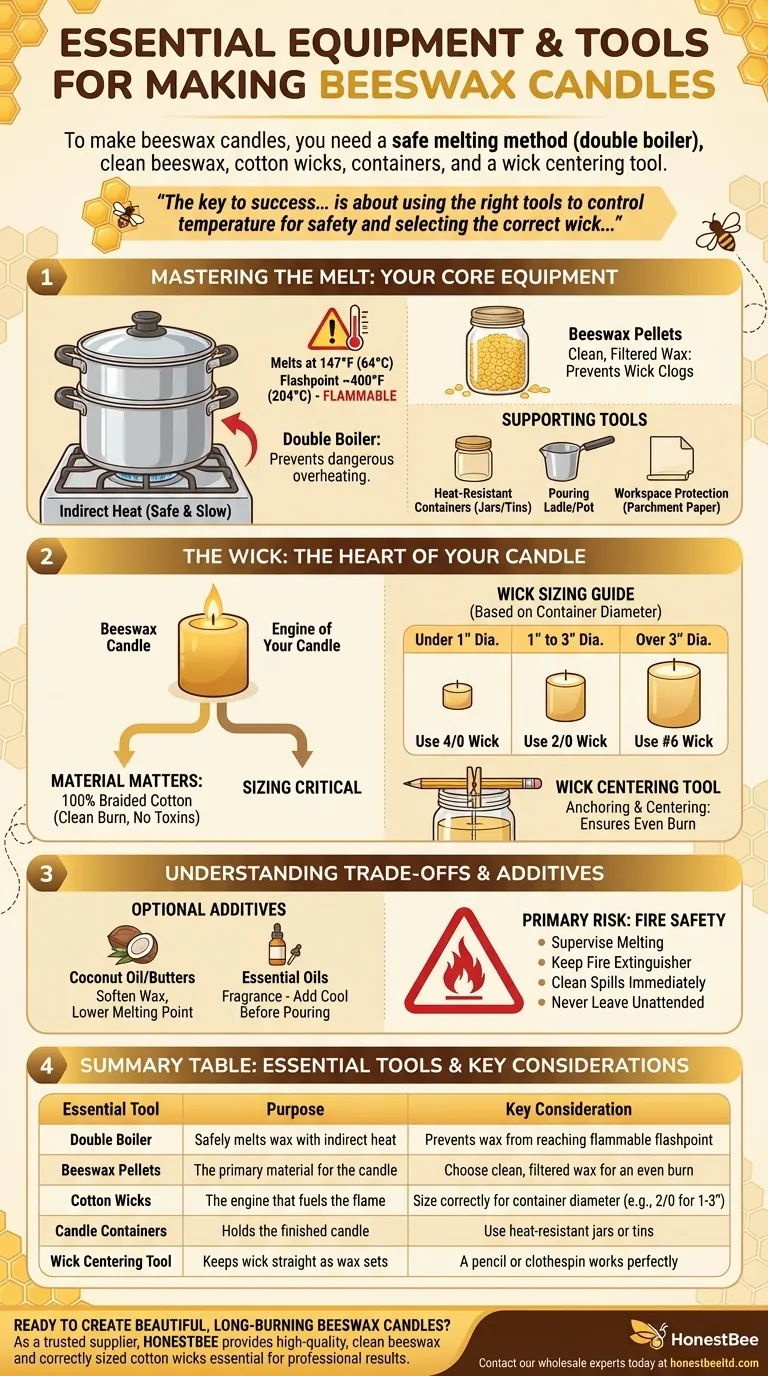

To make beeswax candles, you need a method for safely melting the wax, such as a double boiler, the beeswax itself, and appropriately sized cotton wicks. You will also need containers for the candles and a simple tool like a clothespin or pencil to hold the wick centered as the wax sets.

The key to success in beeswax candle making isn't just gathering supplies; it's about using the right tools to control temperature for safety and selecting the correct wick to ensure a clean, consistent burn.

Mastering the Melt: Your Core Equipment

The most critical phase of candle making is melting the beeswax. This process requires specific tools to ensure both safety and a quality outcome.

The Double Boiler: Your Non-Negotiable Safety Tool

A double boiler is the safest method for melting beeswax because it provides slow, steady, and indirect heat. Beeswax melts at a relatively low temperature of 147°F (64°C).

However, it is flammable and can ignite if it reaches its flashpoint of around 400°F (204°C). A double boiler makes it nearly impossible to overheat the wax to this dangerous level.

If you don’t have a dedicated double boiler, you can create one by placing a heat-resistant glass bowl or a large glass jar inside a larger pot of simmering water. Never melt beeswax directly on a stove burner or in a microwave.

The Wax: Choosing the Right Form

For beginners, beeswax pellets are the ideal choice. They melt much more quickly and evenly than a solid block of wax.

Ensure you are using clean, filtered beeswax. Impurities or debris in the wax can clog the wick, causing the flame to sputter or extinguish itself. Commercially prepared wax is typically already cleaned for this purpose.

Supporting Tools for Melting and Pouring

You will need a few simple tools to handle the hot wax:

- Heat-Resistant Containers: Glass jars or tins to pour your finished candles into.

- Old Ladle or Pouring Pot: A dedicated ladle or a small pot with a spout makes it much easier and safer to transfer the molten wax from your double boiler to your candle containers.

- Workspace Protection: Lay down parchment paper or paper towels to protect your surfaces from wax drips, which can be difficult to clean.

The Wick: The Heart of Your Candle

The wick is not just a string; it is the engine of your candle. The wrong choice here is the most common point of failure for beginners.

Why Material Matters: 100% Cotton Wicks

Always choose wicks made of 100% braided cotton. These wicks burn cleanly and do not release the toxins or caustic substances that can be found in wicks containing metal cores.

Sizing Your Wick: The Critical Decision

Beeswax burns hotter and requires more energy to melt than paraffin or soy wax. Therefore, you must use a wick properly sized for the diameter of your candle.

A wick that is too small will "tunnel," leaving a thick wall of unmelted wax. A wick that is too large will produce a dangerously large flame, smoke, and soot.

- For candles under 1" in diameter: Use a 4/0 wick.

- For candles 1" to 3" in diameter: Use a 2/0 wick.

- For candles over 3" in diameter: Use a #6 wick.

Centering and Anchoring the Wick

For an even burn, the wick must remain perfectly centered and taut while the wax cools.

You can anchor the metal tab of the wick to the bottom of your container with a dab of hot glue. To keep it centered at the top, lay a pencil or clothespin across the mouth of the container and secure the wick to it.

Understanding the Trade-offs and Additives

While a basic candle only requires wax and a wick, you can introduce other elements. It's important to understand their purpose and potential impact.

Optional Additives: Oils and Butters

Some recipes call for adding coconut oil or other butters. This is done to soften the wax, which can slightly lower its melting point and potentially create a smoother, more consistent burn in certain blends.

Essential oils can be added for fragrance. Add them just before you pour, when the wax has cooled slightly, to prevent the delicate scents from burning off. These are optional and not required for a functional candle.

The Primary Risk: Fire Safety

The most significant risk is fire. Always supervise wax while it is melting. Keep a fire extinguisher rated for grease fires nearby. Clean up any spills immediately to prevent accidents.

Never leave a burning candle, homemade or otherwise, unattended.

Making the Right Choice for Your Goal

Your equipment needs can be tailored to what you want to achieve with your candle-making project.

- If your primary focus is safety and a successful first batch: Prioritize a proper double boiler (or a safe DIY version) and meticulously follow all heating precautions.

- If your primary focus is a high-quality, long-burning candle: Pay closest attention to using clean beeswax and carefully matching your cotton wick size to your container's diameter.

- If your primary focus is creating a signature scented candle: Master the basic wax and wick combination first, then begin experimenting with small amounts of essential oils and coconut oil.

With the right tools and an understanding of the principles, you are equipped to create beautiful and functional beeswax candles safely.

Summary Table:

| Essential Tool | Purpose | Key Consideration |

|---|---|---|

| Double Boiler | Safely melts wax with indirect heat | Prevents wax from reaching flammable flashpoint |

| Beeswax Pellets | The primary material for the candle | Choose clean, filtered wax for an even burn |

| Cotton Wicks | The engine that fuels the flame | Size correctly for container diameter (e.g., 2/0 for 1-3") |

| Candle Containers | Holds the finished candle | Use heat-resistant jars or tins |

| Wick Centering Tool | Keeps wick straight as wax sets | A pencil or clothespin works perfectly |

Ready to create beautiful, long-burning beeswax candles?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the high-quality, clean beeswax and correctly sized cotton wicks essential for professional results. Let us equip you for success.

Contact our wholesale experts today to discuss your supply needs.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional 3-Bar Frame Grip with Integrated Hive Tool

People Also Ask

- What is the step-by-step process for making a beeswax candle? Master the Art of Professional Candle Manufacturing

- What equipment is required for manufacturing beeswax candles? Professional Tools for High-Quality Production

- How can clean, filtered beeswax be remelted and molded? Master the Safe Double Boiler Method

- What is the purpose of using mold release spray in candle making? Ensure Perfect Candle Release Every Time

- How do additives like essential oils or cocoa butter influence a beeswax candle? Expert Guide to Scents & Textures

- How can beeswax be acquired for candle making? Sourcing Tips for Quality & Convenience

- What factors should be considered when selecting a wick for beeswax candles? A Guide to a Perfect Burn

- How does the inclusion of beeswax aromatherapy candles improve the economic efficiency of a commercial apiary?