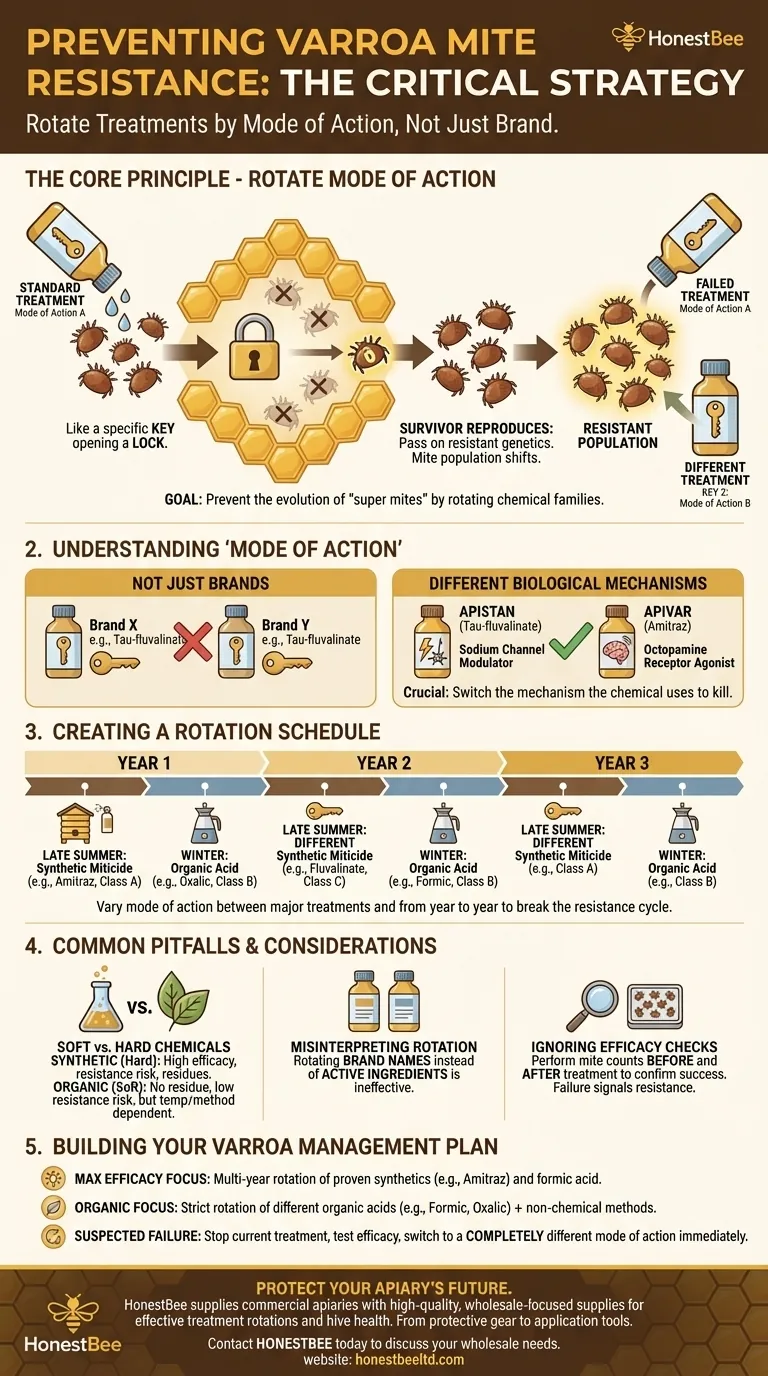

The most critical strategy to prevent Varroa mite resistance is to systematically rotate the chemical treatments used in your hives. This means intentionally varying the type of treatment, and more specifically its chemical family or "mode of action," over time. Simply using the same product year after year creates intense selective pressure that allows genetically resistant mites to survive, reproduce, and eventually render that treatment useless.

Your goal is not just to kill mites, but to prevent the evolution of "super mites" within your own hives. This is achieved by rotating between different modes of action, ensuring no single mite lineage with a natural defense against one chemical can ever become dominant.

Why Treatment Rotation is Essential

To effectively manage Varroa long-term, you must understand the mechanics of resistance. It is a predictable outcome of repeated, singular pressure on a pest population.

The Mechanics of Resistance

Think of a treatment as a specific "key" designed to open a "lock" (a biological pathway) in the mite. In any large mite population, a few individuals will, by random genetic chance, have a slightly different lock that your key doesn't fit.

When you use the same treatment (the same key) over and over, you kill all the mites with the standard lock. The only ones left are those few with the different lock. These survivors then reproduce, passing on their resistant genetics until the entire hive is full of mites that your key can no longer open.

What "Mode of Action" Means

This is the most misunderstood part of treatment rotation. Rotating brands is not enough; you must rotate the mode of action, which is the specific biological mechanism a chemical uses to kill the mite.

For example, Apistan (active ingredient: tau-fluvalinate) and Apivar (active ingredient: amitraz) are different products, but more importantly, they have different modes of action. Fluvalinate is a sodium channel modulator, while amitraz is an octopamine receptor agonist. Rotating between them is effective because mites resistant to one are not typically resistant to the other.

Creating a Rotation Schedule

A robust schedule involves changing the mode of action both between major treatments and from year to year. A beekeeper might use a synthetic miticide in the late summer one year, followed by an organic acid "clean-up" treatment in the winter.

The following year, they should choose a different synthetic miticide with a different mode of action for their main summer treatment to break the cycle of resistance.

Common Pitfalls and Considerations

A successful strategy requires avoiding common mistakes and understanding the trade-offs of different treatment types.

The "Soft" vs. "Hard" Chemical Dilemma

Synthetic miticides (the "hard" chemicals like amitraz and fluvalinate) are generally highly effective and easy to apply. However, they carry a higher risk of building resistance and can leave trace residues in wax.

Organic acids (the "soft" chemicals like formic and oxalic acid) are naturally occurring and leave no long-term residues. Resistance is not a significant concern with them, but their effectiveness can be highly dependent on temperature and application method, making them less forgiving.

Misinterpreting "Rotation"

The most common mistake is rotating product brand names instead of active ingredients. For example, switching between two different brands that both use tau-fluvalinate does absolutely nothing to combat resistance. Always read the label to identify the active ingredient and its chemical class.

Ignoring Treatment Efficacy Checks

You cannot know if your strategy is working unless you measure it. Always perform a mite count (using an alcohol wash or sugar roll) before you treat to establish a baseline and after the treatment period to confirm its effectiveness. A treatment that fails to significantly reduce mite counts is a clear signal of developing resistance.

Building Your Varroa Management Plan

Your ideal rotation depends on your beekeeping philosophy and the specific pressures in your area.

- If your primary focus is maximum efficacy: A multi-year rotation between a proven synthetic like Apivar (amitraz) for one year's main treatment and a formic acid-based treatment (like Formic Pro) for the next year's main treatment is a powerful strategy.

- If your primary focus is organic or treatment-free beekeeping: Rely on a strict rotation of different organic acids (e.g., formic acid in the summer, oxalic acid vapor in the winter) combined with non-chemical methods like drone brood removal.

- If you suspect a treatment has failed: Immediately stop using that chemical, perform an efficacy test to confirm, and switch to a product with a completely different mode of action to regain control of the mite population.

By thinking like an adversary and systematically varying your attack, you move from simply reacting to mites to proactively managing the long-term health of your apiary.

Summary Table:

| Strategy | Key Action | Why It Matters |

|---|---|---|

| Core Principle | Rotate treatments by mode of action, not just brand. | Prevents a single resistant mite lineage from dominating. |

| Common Mistake | Rotating brand names but using the same active ingredient. | Does nothing to combat resistance; wastes time and money. |

| Effective Rotation | Switch between chemical classes (e.g., Amitraz, then Fluvalinate). | Mites resistant to one mode of action are vulnerable to another. |

| Supporting Action | Perform mite counts before and after each treatment. | Confirms efficacy and provides early warning of resistance. |

Protect your apiary's future with the right equipment. A successful Varroa management plan requires reliable tools. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused supplies needed to implement effective treatment rotations and maintain hive health. From protective gear to precise application tools, we support your operation's success.

Contact HONESTBEE today to discuss your wholesale equipment needs and build a more resilient beekeeping business.

Visual Guide

Related Products

- Adjustable Formic and Acetic Acid Dispenser for Bee Mite Treatment

- Varroa Easy Check Mite Tester Kit Counter Alcohol Wash Jar

- Economy Galvanized Beekeeping Honey Bee Smoker for Wholesale

- Plastic Chinese Queen Grafting Tool for Bee Queen Rearing

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What are the technical requirements for Varroa mite treatments? Essential Strategies for Colony Health

- What is the application method for cardboard-based Varroa mite treatments? Maximize Hive Health with Correct Placement

- What is a beehive's inner cover and how is it used? Essential Guide for Hive Insulation and Ventilation

- How should Varroa mite treatments be integrated into the spring beekeeping schedule? Expert April-May Timing Guide

- What are the common technical treatments used for Varroa mite control in the spring? Optimize Colony Health Today