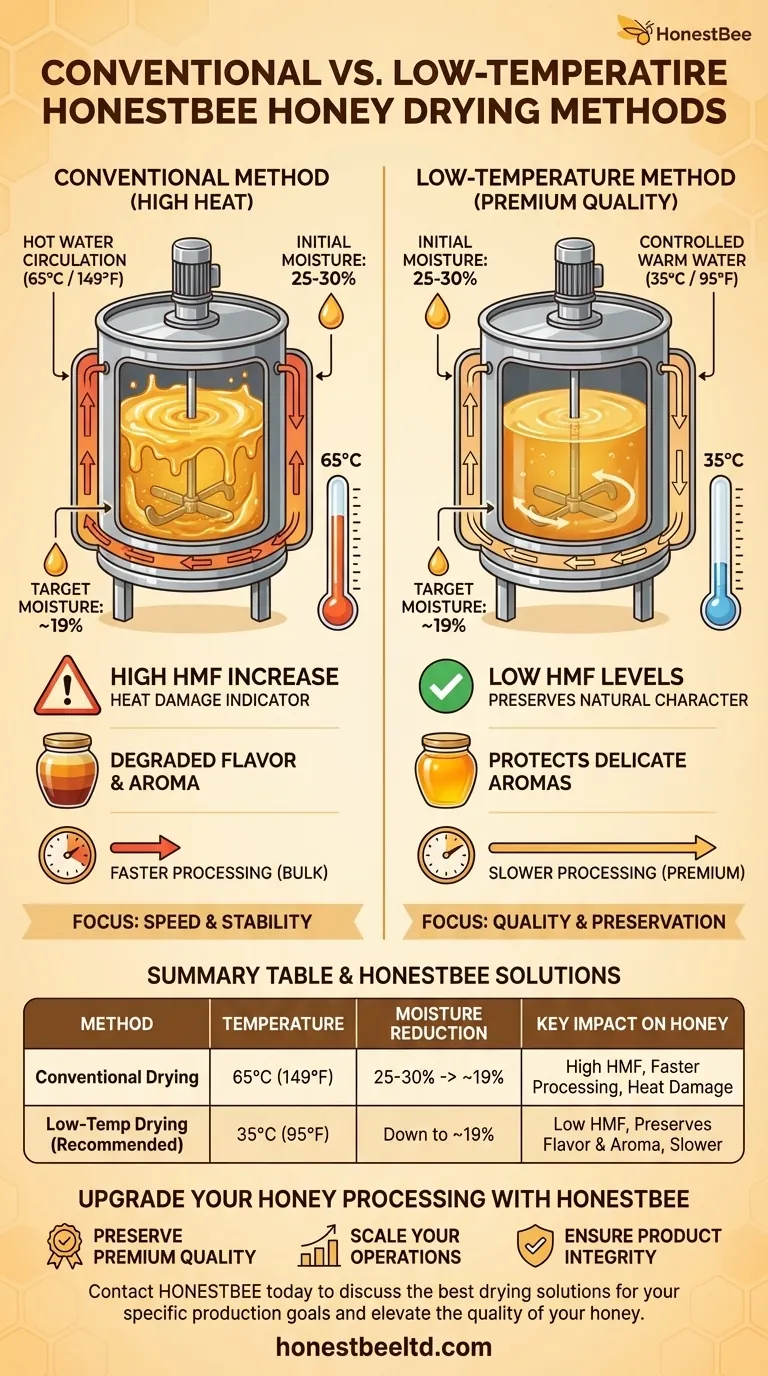

The conventional method for drying honey involves placing it inside a large, jacketed drum where it is continuously stirred. Hot water, typically at 65°C (149°F), is circulated through the outer jacket to heat the honey indirectly, reducing its moisture content from a high of 25-30% down to a more stable level of around 19%.

While conventional drying effectively reduces moisture to prevent fermentation, the high heat involved creates a critical trade-off. This process significantly increases levels of HMF (Hydroxymethylfurfural), a key indicator of heat damage that can negatively alter the honey's flavor and aroma.

How Conventional Honey Drying Works

The Core Equipment

The process relies on a specialized tank or drum equipped with an internal stirring mechanism. This drum is double-walled, creating a "jacket" around the honey container.

The Indirect Heating Process

Instead of heating the honey directly, which could cause scorching, hot water is circulated through the outer jacket. This provides a gentle and consistent heat transfer, raising the honey's temperature to the target of 65°C (149°F).

The Primary Goal: Moisture Reduction

Freshly harvested honey can have a moisture content as high as 30%. This excess water makes it susceptible to fermentation by wild yeasts. The drying process aims to reduce this moisture to 19% or less, which is the standard for ensuring long-term shelf stability.

Preserving Aromatics

To prevent the loss of delicate floral aromas and fragrances during heating, this process often takes place in a sealed, air-lock tank. This environment helps trap the volatile compounds that give honey its unique character.

Understanding the Trade-off: Heat vs. Quality

The Problem with Heat: HMF Formation

Hydroxymethylfurfural (HMF) is a compound formed when sugars are broken down by heat. Its presence in honey is a universally accepted indicator of heat exposure and overall quality. Fresh, raw honey has very little to no HMF.

The Impact of High Temperatures

Heating honey above 35°C (95°F) causes HMF levels to rise. At the conventional drying temperature of 65°C, this increase is significant, with HMF content often reaching levels as high as 40%.

What High HMF Signifies

High HMF content indicates that the honey has been heat-treated, is of poor quality, or has potentially been adulterated. This heat damage degrades the delicate flavor and aroma profile, making the honey less desirable to consumers seeking a premium product.

The Alternative: Low-Temperature Drying for Quality

A Focus on Preservation

To avoid quality degradation, a recommended best practice is to dry honey at a much lower temperature. The ideal target is around 35°C (95°F).

Balancing Moisture and HMF

Drying at this lower temperature still achieves the target moisture content of 19%. However, it keeps the HMF content significantly lower—around 25%—preserving the natural characteristics of the honey.

The Implication for Processors

While low-temperature drying produces a far superior product, it takes much longer than the conventional high-heat method. This makes it a choice between prioritizing processing speed and efficiency versus preserving premium quality.

How to Apply This to Your Goal

Choosing the right drying method requires a clear understanding of your final product goals.

- If your primary focus is bulk processing and stability: The conventional high-heat method (65°C) is faster and effectively prevents fermentation, making it suitable for large-scale operations where premium quality is not the main driver.

- If your primary focus is preserving premium quality: A low-temperature method (35°C) is essential to minimize HMF formation, protect delicate aromas, and maintain the honey's raw, natural character.

Ultimately, controlling heat exposure is the single most important factor in balancing the shelf stability and the intrinsic quality of the final honey product.

Summary Table:

| Method | Temperature | Moisture Reduction | Key Impact on Honey |

|---|---|---|---|

| Conventional Drying | 65°C (149°F) | 25-30% down to ~19% | High HMF increase; faster processing |

| Low-Temp Drying (Recommended) | 35°C (95°F) | Down to ~19% | Low HMF; preserves flavor & aroma |

Upgrade Your Honey Processing with HONESTBEE

For commercial apiaries and beekeeping equipment distributors, choosing the right drying equipment is critical for product quality and operational efficiency. HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment designed to support both conventional and low-temperature drying methods.

We help you:

- Preserve Premium Quality: Source equipment that enables gentle, low-heat drying to minimize HMF and protect your honey's natural profile.

- Scale Your Operations: Access robust, high-capacity solutions for efficient bulk processing.

- Ensure Product Integrity: Get the right tools to control moisture content precisely and ensure shelf stability.

Contact HONESTBEE today to discuss the best drying solutions for your specific production goals and elevate the quality of your honey.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How can the moisture content of honey be reduced? A Guide to Safe, Effective Drying Methods

- What is the recommended operating temperature for drying honey? Preserve Quality and Enzymes with Precision Heating

- What is the role of a spray dryer with air dehumidification for honey powder? Master Humidity for Quality Output

- Why use shallow trays for honey dehydration? Optimize Evaporation and Preserve Enzyme Integrity

- What are the features of the honey dryer? Achieve Premium Quality & Maximize Your Harvest

- What are the processing advantages of using industrial dehumidification equipment for high-moisture tropical honey?

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- Why is moisture control important during honey drying? Prevent Fermentation & Ensure Quality