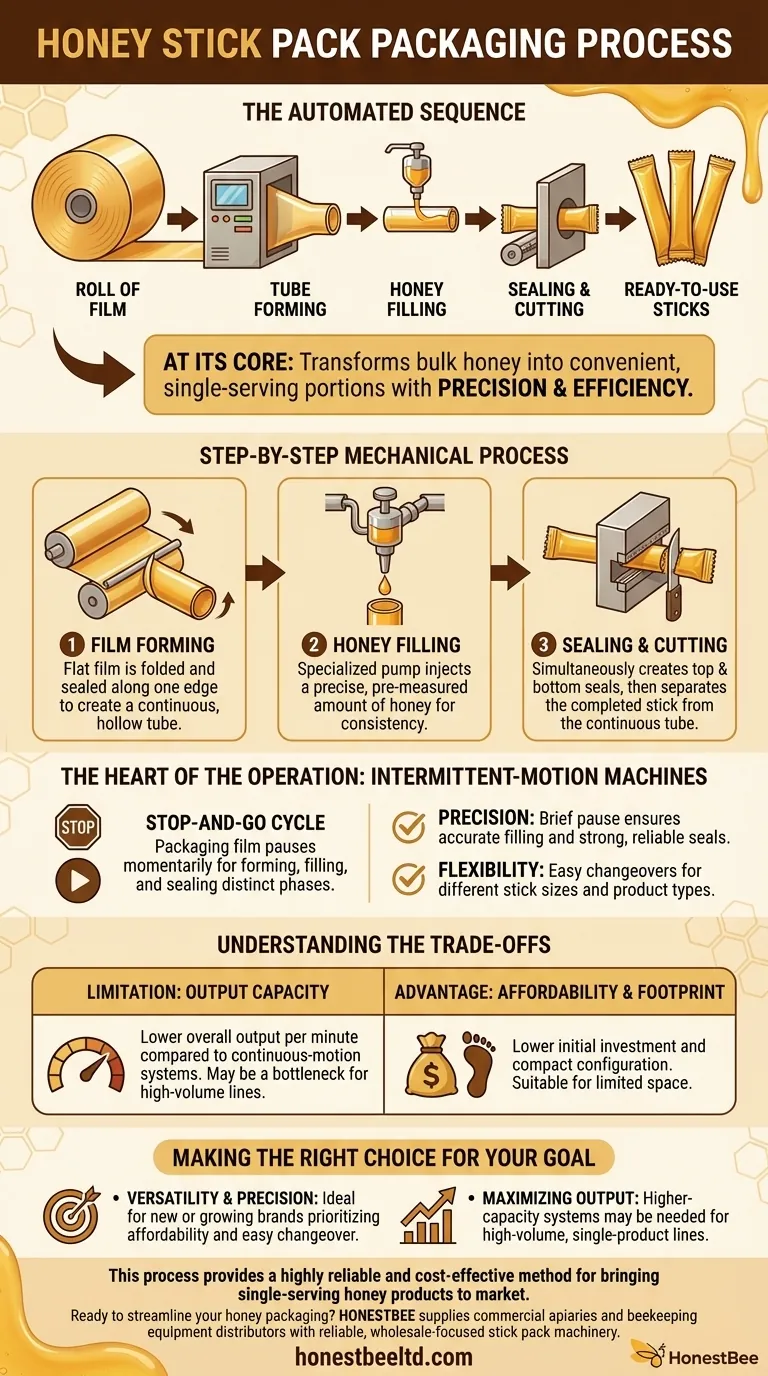

At its core, the stick pack packaging process for honey is an automated sequence where a roll of packaging film is formed into a tube, filled with honey, then sealed and cut into individual, ready-to-use sticks. This method transforms bulk honey into convenient, single-serving portions with precision and efficiency.

The key takeaway is that the most common method for honey stick packaging uses an intermittent-motion machine. This "stop-and-go" process prioritizes high precision and flexibility over raw speed, making it an ideal and affordable solution for many producers.

The Step-by-Step Mechanical Process

The entire operation is handled by a single, integrated machine that executes a precise cycle of forming, filling, and sealing.

Step 1: Film Forming

The process begins with a large roll of flat packaging film, which is fed from a roller into the machine. This film is then expertly folded and sealed along one edge to create a continuous, hollow tube, which will become the body of the sticks.

Step 2: Honey Filling

Once the tube is formed, a specialized pump injects a precise, pre-measured amount of honey into it. This step is critical for ensuring product consistency and minimizing waste.

Step 3: Sealing and Cutting

After the honey is dispensed, the machine simultaneously creates a top seal for the filled portion and a bottom seal for the next stick. A cutting mechanism then separates the completed, filled-and-sealed stick from the continuous tube. This cycle repeats rapidly.

The Heart of the Operation: Intermittent-Motion Machines

The specific type of machinery often used for honey stick packs operates on an intermittent-motion principle. Understanding this concept is key to understanding the entire process.

What "Intermittent-Motion" Means

This describes a "stop-and-go" operational cycle. The packaging film pauses momentarily for each distinct phase: forming, filling, and sealing. It is not a continuous, fluid motion.

The Advantage of Precision

The brief pause between cycles allows for extremely high precision. This ensures each stick is filled with the correct amount of honey and that the seals are strong and reliable, which is crucial for a viscous product like honey.

The Benefit of Flexibility

Intermittent-motion machines are known for their versatility. They can often be reconfigured for different stick sizes or product types with relatively easy changeovers, offering producers significant operational flexibility.

Understanding the Trade-offs

While effective, this method involves a clear balance between different production priorities.

The Primary Limitation: Output Capacity

The stop-and-go nature of the process inherently limits its top speed. Compared to continuous-motion systems used for other products, the overall output of honey sticks per minute is lower.

The Key Advantage: Affordability and Footprint

The trade-off for lower speed is often a lower initial investment. These machines typically have a more compact configuration, making them more affordable and suitable for facilities with limited space.

Making the Right Choice for Your Goal

Selecting a packaging process depends entirely on your production scale and business strategy.

- If your primary focus is versatility and precision for a new or growing brand: The affordability and easy changeover of an intermittent-motion process is an excellent starting point.

- If your primary focus is maximizing output for a high-volume, single-product line: The slower speed might become a bottleneck, and a higher-capacity system may eventually be necessary.

This process provides a highly reliable and cost-effective method for bringing single-serving honey products to market.

Summary Table:

| Process Step | Key Action | Machine Function |

|---|---|---|

| 1. Film Forming | Flat film is folded & sealed | Creates a continuous tube |

| 2. Honey Filling | Precise amount of honey is injected | Specialized pump ensures accuracy |

| 3. Sealing & Cutting | Top/bottom seals are made & stick is cut | Completes the individual stick pack |

| Machine Type | Intermittent-Motion | Advantages |

| Operation Cycle | Stop-and-go | High precision, strong seals |

| Flexibility | Easy changeover for different sizes | Ideal for varied product lines |

| Trade-offs | Lower speed vs. continuous motion | More affordable, compact footprint |

Ready to streamline your honey packaging?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with reliable, wholesale-focused stick pack machinery and supplies. Our intermittent-motion systems offer the precision and flexibility you need to produce consistent, single-serve honey sticks efficiently.

Contact us today to discuss how our solutions can enhance your production line and grow your brand!

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Durable Customizable Blister Packing Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

People Also Ask

- What factors should be considered when choosing a honey filling machine? Optimize Your Production Line

- What causes film jamming in a honey stick machine and how can it be resolved? 3 Pro Fixes for Seamless Production

- How do automated honey-filling machines ensure that honey products meet industrial quality standards? Boost Consistency

- How do automated and manual filling machines compare? Find the Best Filling Solution for Your Production Scaling

- How does a premade pouch packaging machine work? A Guide to High-Speed, High-Quality Automation

- Why is advanced Honey Packaging Technology essential for commercial honey? Secure Quality and Brand Value

- How do industrial-grade honey filling machines enhance commercial value? Scale Your Brand with Precision Technology

- What technical challenges do honey filling machines solve? Expert Solutions for Viscosity, Waste, and Hygiene