At its core, a bottle capping machine serves a single, critical function: to apply and secure caps onto bottles and other containers. Its purpose is to automate this sealing process, protecting the contents from contamination, preventing leaks, and ensuring the product is tamper-evident and ready for the consumer.

A capping machine's true value is not just in placing a cap, but in bringing repeatable precision, speed, and safety to a packaging line. It transforms a variable, labor-intensive task into a reliable and efficient automated process.

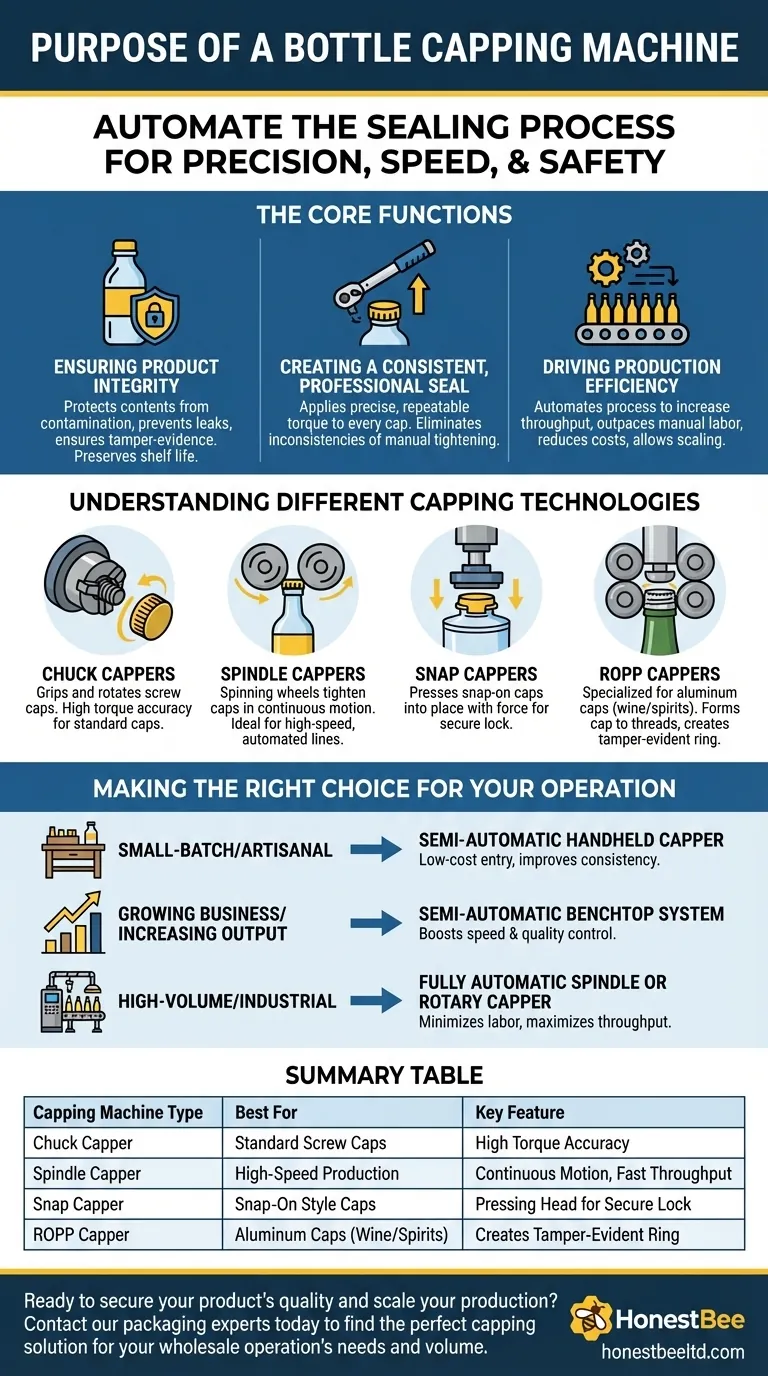

The Core Functions: More Than Just Twisting a Cap

While the primary function is simple, a capping machine accomplishes several critical objectives for any production environment.

Ensuring Product Integrity

A proper seal is the first line of defense for your product. An automated capper creates a secure, often hermetic seal that protects against oxygen, moisture, and microbial contamination.

This function is non-negotiable for preserving the shelf life and safety of foods, beverages, pharmaceuticals, and chemical products.

Creating a Consistent, Professional Seal

Manual tightening is inherently inconsistent. Some caps will be too loose, risking leaks and spoilage, while others will be too tight, making them difficult for consumers to open and potentially damaging the container.

Capping machines apply a precise and repeatable amount of torque to every single cap. This consistency ensures a reliable seal, prevents damage, and projects a high-quality, professional image for your brand.

Driving Production Efficiency

In any commercial operation, the capping station can quickly become a bottleneck. Automating this process dramatically increases throughput.

Machines can cap hundreds or even thousands of bottles per hour, far outpacing manual labor. This reduces labor costs, streamlines the entire packaging line, and allows for significant scaling of production.

Understanding the Different Capping Technologies

Not all caps and bottles are the same, which is why different types of capping machines exist to handle specific needs.

Chuck Cappers

These machines use a "chuck" that grips the cap and rotates to tighten it onto the bottle's threads. They are known for their high torque accuracy and are common in both semi-automatic and fully automatic systems for standard screw caps.

Spindle Cappers

Spindle cappers use sets of spinning wheels or discs that make contact with the cap as the bottle passes by on a conveyor. Each successive set of wheels tightens the cap further.

This design allows for continuous motion, making spindle cappers extremely fast and ideal for high-speed, fully automated production lines.

Snap Cappers

As the name implies, these machines are designed to press "snap-on" style caps firmly onto a container until they lock into place. This is achieved with a pressing head or a specialized belt system.

ROPP Cappers

ROPP (Roll-On Pilfer-Proof) cappers are specialized machines used for aluminum caps, common on wine and spirits bottles. The machine places a straight-walled aluminum shell over the bottle neck and then forming rollers shape the shell to the threads and create a tamper-evident ring.

Making the Right Choice for Your Operation

The right capping solution depends entirely on your production volume, container type, and business goals.

- If your primary focus is small-batch or artisanal production: A handheld semi-automatic capper offers a low-cost entry point that dramatically improves consistency over hand-tightening.

- If your primary focus is growing your business and increasing output: A semi-automatic benchtop system provides a crucial bridge, boosting speed and quality control without the expense of a fully integrated line.

- If your primary focus is high-volume, industrial-scale manufacturing: A fully automatic spindle or rotary capping machine is essential for minimizing labor costs and maximizing throughput.

Ultimately, a capping machine is a strategic investment in the quality, safety, and efficiency of your entire packaging process.

Summary Table:

| Capping Machine Type | Best For | Key Feature |

|---|---|---|

| Chuck Capper | Standard Screw Caps | High Torque Accuracy |

| Spindle Capper | High-Speed Production | Continuous Motion, Fast Throughput |

| Snap Capper | Snap-On Style Caps | Pressing Head for Secure Lock |

| ROPP Capper | Aluminum Caps (Wine/Spirits) | Creates Tamper-Evident Ring |

Ready to secure your product's quality and scale your production?

At HONESTBEE, we specialize in supplying robust and reliable bottle capping solutions tailored for commercial apiaries and beekeeping equipment distributors. Whether you're bottling honey, syrups, or other products, the right capping machine is a critical investment in protecting your brand and boosting your output.

Contact our packaging experts today to find the perfect capping solution for your wholesale operation's needs and volume.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Semi Automatic Electric Bottle Capping Machine

- Automatic In-Line Round Bottle Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What is the working principle of bottle packing machine? Achieve Efficient, Automated Filling

- What are the different types of capping machines available? Choose the Right One for Your Production Scale

- What is the function of a capping machine in honey packaging? Secure Your Product Quality and Shelf Life

- What types of caps can capping machines handle? Find the Right Solution for Your Bottling Line

- What are the main types of caps supported by bottle capping equipment? Threaded, Press-On, and Insertion

- What are the categories of bottle capping machines? Choose the Right Automation for Your Line

- How does a bottle machine work? Master the Automated Bottling Process

- What is the purpose of bottle capping equipment and what types are available? Professional Sealing Solutions