In packaging and manufacturing, the volumetric filling method is a technique used to dispense a highly precise and repeatable volume of product into a container. It operates by trapping a specific quantity of liquid or semi-liquid in a chamber—most often a cylinder—and then mechanically forcing that entire amount into the container. This process ensures that every package receives the exact same quantity of product, regardless of minor variations in container shape or size.

Volumetric filling is fundamentally about quantity control. It prioritizes delivering an exact, consistent dose of product, making it the definitive choice for applications where product cost, dosage accuracy, and regulatory compliance are more critical than achieving a perfectly uniform cosmetic fill height.

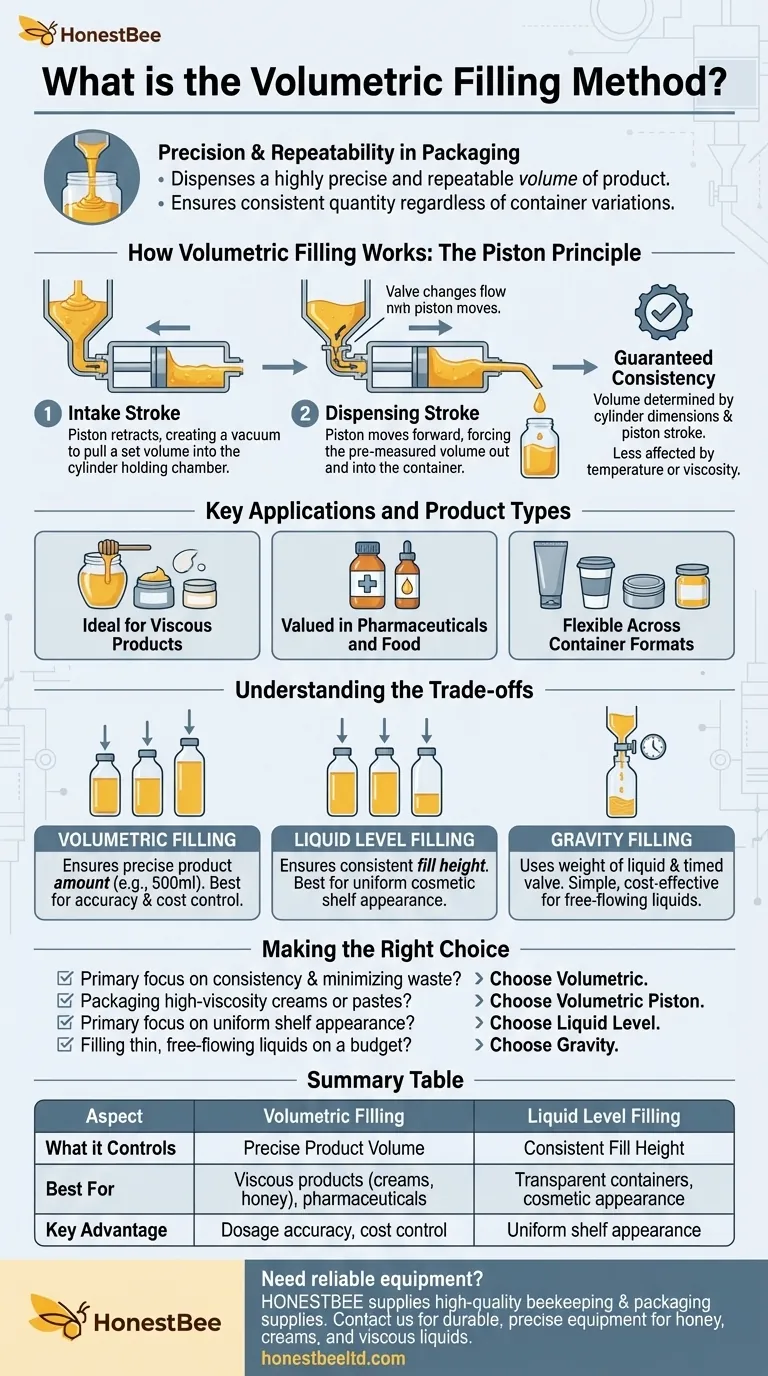

How Volumetric Filling Works: The Piston Principle

The most common mechanism for volumetric filling is the positive displacement piston pump. The process is a simple, highly repeatable two-stroke cycle.

The Intake Stroke

A piston retracts within a precisely machined cylinder, creating a vacuum. This action pulls a set volume of product from a holding tank or hopper into the cylinder chamber. The volume is determined by the cylinder's diameter and the distance the piston travels.

The Dispensing Stroke

Once the cylinder is full, a valve system changes the flow path. The piston then moves forward, pushing the trapped product out of the cylinder and through a nozzle into the waiting container. Because the volume is pre-measured in the cylinder, the entire dose is dispensed with exceptional accuracy.

Why This Guarantees Consistency

The accuracy of a volumetric filler is rooted in its mechanical design. The volume dispensed is a direct function of the cylinder's dimensions and the piston's stroke length—both of which are fixed and repeatable. This makes the system far less susceptible to variations caused by product temperature, viscosity changes, or pressure fluctuations compared to other methods.

Key Applications and Product Types

Volumetric fillers are prized for their versatility and precision, making them essential in numerous industries.

Ideal for Viscous Products

The positive force of the piston makes this method perfect for thick products that do not flow easily on their own. This includes items like honey, sauces, creams, lotions, and gels.

Valued in Pharmaceuticals and Food

In industries where dosage accuracy is non-negotiable, volumetric filling is the standard. It ensures that every bottle of medicine, food supplement, or syrup contains the precise amount of active ingredient or product specified on the label.

Flexible Across Container Formats

These machines can be adapted to fill a wide range of container types and sizes, from small toothpaste tubes and yogurt cups to larger paint tins and jars.

Understanding the Trade-offs: Volumetric vs. Other Methods

Choosing the right filling technology depends entirely on your product and priorities.

Volumetric vs. Liquid Level Filling

A volumetric filler ensures each container has the same amount of product (e.g., 500ml). A liquid level filler, by contrast, fills each container to the same height, which is ideal for transparent containers where a consistent appearance on the shelf is key. However, if the containers themselves have slight volume variations, the actual amount of product will differ.

Volumetric vs. Gravity Filling

A gravity filler uses the weight of the liquid to fill containers through a timed valve. This method is simple and cost-effective but works best with thin, free-flowing liquids. It lacks the power and precision of a volumetric piston filler for handling thicker or more valuable products.

Potential Limitations

While highly accurate, volumetric piston fillers have more moving parts than simpler systems like gravity fillers. This can mean more time is required for cleaning and changeover between different products, which is a key consideration for facilities with high product variability.

Making the Right Choice for Your Production Line

Selecting the correct filling method requires a clear understanding of your primary goal.

- If your primary focus is product consistency and minimizing waste: Volumetric filling is the superior choice because it guarantees a precise dose regardless of container variations.

- If you are packaging high-viscosity products like creams or pastes: The positive displacement action of a volumetric piston filler provides the force needed to move thick liquids accurately and efficiently.

- If your primary focus is a uniform cosmetic appearance on the shelf: A liquid-level filler is often more appropriate, especially for transparent bottles where fill height consistency is paramount.

- If you are only filling thin, free-flowing liquids on a budget-conscious line: A simpler gravity filler can be a perfectly suitable and cost-effective alternative.

Ultimately, aligning the filling technology with your product's characteristics and business objectives is the key to an efficient and profitable packaging operation.

Summary Table:

| Aspect | Volumetric Filling | Liquid Level Filling |

|---|---|---|

| What it Controls | Precise Product Volume | Consistent Fill Height |

| Best For | Viscous products (creams, honey), pharmaceuticals | Transparent containers, cosmetic appearance |

| Key Advantage | Dosage accuracy, cost control | Uniform shelf appearance |

Need a reliable supply of equipment for your packaging line? HONESTBEE supplies high-quality beekeeping and packaging supplies to commercial apiaries and distributors through wholesale-focused operations. If you require durable, precise equipment to handle products like honey, creams, or other viscous liquids, we can support your business. Contact us today to discuss your wholesale needs and how we can help you achieve consistent, efficient packaging.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- How do automated honey filling machines function? Enhance Efficiency and Purity in Honey Packaging

- How do industrial honey filling machines protect monofloral honey value? Secure Premium Pricing with Precision

- How does the real-time validation mechanism in honey-filling machine software assist operators? Ensure Filling Accuracy

- How many types of filling machines are there? A Guide to Choosing the Right Equipment

- Why are specific moisture control and honey-filling machines required? Protect Your Harvest During Rainy Seasons

- What is the core value of automated honey filling machines? Scale Your Production and Ensure Global Quality Standards

- What role do honey filling machines play in enhancing the value of organic honey? Protect Purity and Scale Your Brand

- What is the significance of specialized honey filling equipment? Scaling from Beekeeping to Commercial Success