Beeswax Melter

Electric Commercial Beeswax Melter for Factory Use

Item Number : BWM-2

Price varies based on specs and customizations

- Material

- 304 stainless steel

- Power

- 27KW

- Voltage

- Three-phase 380V

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

The electric beeswax melter is a highly efficient and reliable solution designed for commercial and industrial applications, particularly in environments such as factories, large-scale beekeeping operations, and wax processing facilities. Its robust construction and advanced heating system make it ideal for melting beeswax efficiently and maintaining consistent quality in high-volume production settings.

This commercial beeswax melter is perfect for businesses that require a dependable and durable solution for processing large quantities of beeswax. Whether you are producing candles, cosmetics, or other wax-based products, this melter ensures a seamless and efficient workflow. Its design caters to the needs of modern factories, where precision, speed, and reliability are paramount.

Key applications include:

- Beeswax processing for candle production: Ensures a consistent and high-quality wax supply for candle manufacturers.

- Cosmetic and skincare product manufacturing: Provides pure, filtered beeswax for use in lotions, balms, and creams.

- Industrial wax processing: Suitable for large-scale operations requiring efficient and continuous wax melting.

- Beekeeping operations: Helps beekeepers process honeycombs into reusable wax for hive maintenance or resale.

Features

The electric beeswax melter stands out due to its exceptional build quality and advanced features, making it a top choice for commercial and industrial use. Constructed from 304 stainless steel, it offers superior durability and resistance to corrosion, ensuring a long lifespan even in demanding environments.

Key features include:

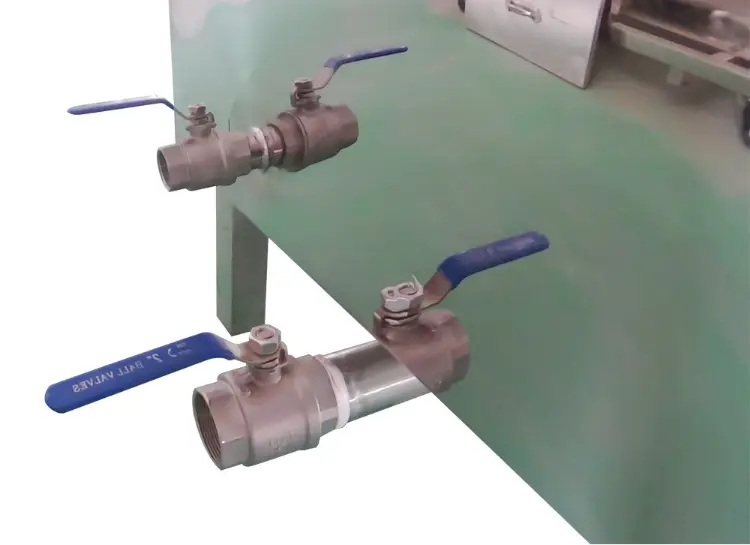

- High-quality 304 stainless steel construction: The melter is built with 2mm thick stainless steel on both the inside and outside, providing strength and durability.

- Efficient heat transfer oil heating system: Powered by 27KW and designed for three-phase 380V operation, this system ensures rapid and uniform heating.

- Insulated design: The outermost layer is equipped with high-temperature-resistant insulation cotton, minimizing heat loss and improving energy efficiency.

- Generous capacity: With inner dimensions of 900*490*500mm, it can handle large volumes of beeswax, making it ideal for factory-scale operations.

- Precision temperature control: The heat transfer oil system allows for precise temperature regulation, ensuring optimal melting conditions.

These features combine to create a reliable and efficient beeswax melter that meets the demands of modern industrial applications.

Principle

The principle behind the electric beeswax melter is straightforward yet highly effective. It operates by heating honeycombs loaded into the tank to a temperature above +70°C, which causes the wax to melt into a liquid state. This liquid wax is then filtered and used for its intended purpose, whether in candle production, cosmetics, or other applications.

The process involves:

- Loading honeycombs: Raw honeycombs are placed into the melter's tank.

- Heating: The heat transfer oil system rapidly heats the contents to the required temperature.

- Melting: As the temperature rises, the beeswax melts and separates from impurities.

- Filtering: The liquid wax is filtered to remove any remaining debris, ensuring a pure final product.

- Collection: The filtered wax is collected for use in various applications.

This process is consistent and reliable, regardless of the specific design or energy source used, making it a versatile solution for beeswax processing.

Advantages

The electric beeswax melter offers numerous advantages that make it a standout choice for commercial and industrial users. Its design and functionality are tailored to meet the needs of high-volume operations, ensuring efficiency, reliability, and cost-effectiveness.

Key advantages include:

- Durability: Made from 304 stainless steel, the melter is built to withstand heavy use and resist corrosion, ensuring a long service life.

- Energy efficiency: The insulation layer and heat transfer oil system minimize energy consumption, reducing operational costs.

- High capacity: With its large inner dimensions, the melter can process significant quantities of beeswax in a single cycle, boosting productivity.

- Precision and consistency: The advanced heating system ensures uniform temperature control, resulting in consistent wax quality.

- Versatility: Suitable for a wide range of applications, from candle making to cosmetic production, making it a valuable investment for diverse industries.

These advantages make the electric beeswax melter an indispensable tool for businesses looking to streamline their wax processing operations while maintaining high standards of quality and efficiency.

Technical specifications

| Parameter | Specification |

|---|---|

| Material | 304 stainless steel |

| Thickness of stainless steel | 2mm inside, 2mm outside |

| Inner dimensions | 900*490*500mm |

| Power | 27KW |

| Voltage | Three-phase 380V |

| Heating type | Heat transfer oil heating |

| Heat transfer oil requirement | 100kg |

| Insulation layer | High-temperature resistant insulation cotton |

FAQ

What Is The Principle Of A Beeswax Melter?

What Is The Principle Of A Wax Melter?

What Is The Principle Of A Wax Warmer?

What Are The Advantages Of A Steam Beeswax Melter?

What Are The Advantages Of A Wax Melter?

What Are The Advantages Of Using A Wax Warmer?

What Are The Applications Of A Beeswax Melter?

What Are The Applications Of A Wax Melter?

What Are The Main Applications Of A Wax Warmer?

What Are The Main Features Of A Solar Beeswax Melter?

What Are The Main Types Of Wax Melters?

What Are The Different Types Of Wax Warmers Available?

What Types Of Beeswax Melters Are Available?

How Does A Steam Wax Melter Work?

How Does A Wax Warmer Ensure Safety During Use?

4.8 / 5

This melter is a game-changer! Speedy delivery and top-notch quality. Highly recommend for any large-scale operation.

4.9 / 5

Impressive durability and efficiency. The stainless steel build is a standout feature. Worth every penny!

4.7 / 5

Perfect for our factory needs. Consistent heating and large capacity make it a must-have for wax processing.

4.8 / 5

Exceptional value for money. The insulated design saves energy, and the precision control is unmatched.

4.9 / 5

A reliable workhorse! The 304 stainless steel ensures longevity, and the heating system is incredibly efficient.

4.7 / 5

Perfect for high-volume production. The melter’s consistency and ease of use have transformed our workflow.

4.8 / 5

A fantastic investment! The melter’s capacity and advanced features have significantly boosted our productivity.

4.9 / 5

Highly efficient and durable. The precision temperature control ensures perfect wax quality every time.

4.7 / 5

Great for industrial use. The melter’s design is both robust and energy-efficient, making it a standout choice.

4.8 / 5

The melter exceeded expectations! Fast delivery, easy setup, and flawless performance. Highly recommended!

4.9 / 5

A true powerhouse! The melter’s capacity and heating system are ideal for large-scale operations. Very reliable.

4.7 / 5

Perfect for cosmetic production. The melter’s precision and consistency ensure high-quality wax every time.

4.8 / 5

Outstanding build quality and performance. The melter’s energy efficiency is a huge plus for our factory.

4.9 / 5

A top-tier product! The melter’s durability and advanced features make it a must-have for any wax processing facility.

4.7 / 5

Highly efficient and easy to use. The melter’s large capacity has significantly improved our production speed.

4.8 / 5

Exceptional quality and performance. The melter’s precision control ensures consistent results every time.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Electric beeswax flat sheet machine: 750W, stainless steel, 220V. Perfect for beekeepers, ensures uniform wax sheets for honeycomb foundations. Durable, efficient.

Fully Automatic Beeswax Embossing Machine Foundation Mill

Explore high-quality beeswax foundation machines for efficient beekeeping. Durable, customizable, and high-output at 1000 sheets/hour. Ideal for factory manufacturing.

Steam Beeswax Melter Wax Warmer for Wax Processing

Efficient steam beeswax melter for beekeepers, ensures high-quality wax extraction with minimal effort. Durable stainless steel design, 90L capacity. Ideal for candle making and cosmetics.

Electric Flatting and Embossing Machine with Tray for Beekeeping

Flatting and Embossing Machine for beeswax sheets: high efficiency, customizable sizes, and durable aluminum rollers. Ideal for modern beekeeping.

Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

Electric beeswax foundation machine for beekeeping. High-quality, customizable wax sheets, 1200pcs/hour. Durable, efficient, and bee-friendly. Explore now!

Beeswax Melter for Candle Making Honey Bee Wax Melter

1.5L beeswax melter for candle making & crafting. Stainless steel, durable, compact, and easy to clean. Perfect for hobbyists and professionals.

Manual Beeswax Flat Sheet Machine for Beeswax Processing

Beeswax Flat Sheet Machine: Press thick wax blocks into uniform sheets for candles, wraps, and crafts. Stainless steel, customizable rollers, manual operation. Ideal for artisans and manufacturers.

Solar Beeswax Melter Easy Solar Wax Melter for Beeswax

Solar Wax Melter: Eco-friendly beeswax extraction tool. Harness solar energy, durable design, low maintenance. Perfect for sustainable beekeeping and crafting.

Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

Boost beekeeping efficiency with our wax foundation machine. Produces 300-600 uniform sheets/hour. Customizable sizes, durable aluminum alloy. Ideal for healthy hives & increased honey production.

Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

Economy manual beeswax embossing mill for beekeepers. Customizable wax foundation sheets, durable aluminum alloy, 300-600pcs/hour capacity. Enhance hive health and honey production.

Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

Optimize honey processing with the Honey Homogenizer. Efficient 120kg capacity, stainless steel, 40r/min speed. Perfect for beekeepers.

Beeswax Foundation Sheets Beehive Foundation for Wholesale

Beeswax foundation sheets: 100% natural, eco-friendly, customizable sizes. Essential for beekeeping, crafting, and sustainable living. Boost hive health today!

Stainless Steel Electric Beehive Smoker for Beekeeping and Bee Keeper Use

Discover the Stainless Steel Electric Beehive Smoker, designed for safe, efficient beekeeping. Features durable stainless steel, one-button operation, and AA battery power.

Electric 4 Frame Tangential Honey Extractor

Discover the 4-frame electric honey extractor for efficient, durable, and customizable beekeeping solutions. Enhance productivity today!

24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

Optimize honey extraction with our 24-frame stainless steel honey extractor. High-capacity, durable, and customizable for commercial beekeeping. Explore now!

Commercial 48-Frame Stainless Steel Honey Extractor

Explore the **electric 48-frame honey extractor**, a durable stainless steel tool for efficient honey processing. Ideal for commercial beekeeping.

Related Articles

The Biological Clock and the Energy Bill: Why Beeswax is More Valuable Than Honey

Beeswax production is an energy-intensive process tied to a bee's short biological window, forcing a crucial trade-off between hive growth and honey storage.

Stop Paying to Melt Wax: The Simple Physics of a Zero-Cost Apiary Asset

Learn the simple science behind solar wax melters and see why professional-grade units are a smart, zero-cost tool for commercial apiaries.

The Physics of the Honey Harvest: Why Frame Size is an Economic Decision

Discover how frame size dictates honey yield and operational efficiency. Learn why this choice is a critical economic decision for commercial apiaries.

Heat, Honey, and the Commercial Compromise: Why Processing is a Balancing Act

Honey processing involves a critical trade-off: heat extends shelf life but can degrade natural quality. Understanding this balance is key for producers.

Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

Discover how a bee frame forming machine solves beekeeping's hidden bottleneck, shifting focus from manual labor to strategic growth and efficiency.

The Physics of Trust: Why Hive Transport is Beekeeping's Most Underrated Challenge

Moving beehives isn't just heavy lifting; it's a calculated risk involving physics, bee biology, and operational scale. Learn the right approach.

Is Your Beehive Transportation Strategy Cooking Your Colonies?

Discover why traditional beehive transport methods lead to colony loss and how cross-wind ventilation, supported by HONESTBEE equipment, ensures colony survival.