Wax dipping is a wood preservation method where beekeeping equipment is submerged in a vat of hot, molten wax. The high temperature boils any residual moisture out of the wood, allowing the wax to deeply penetrate the grain. This process creates a comprehensive, water-repellent barrier that protects the equipment from the inside out.

Unlike paint, which only creates a surface-level barrier, wax dipping impregnates the wood itself. This offers superior, long-lasting protection against moisture and rot while preserving the wood's natural appearance and texture.

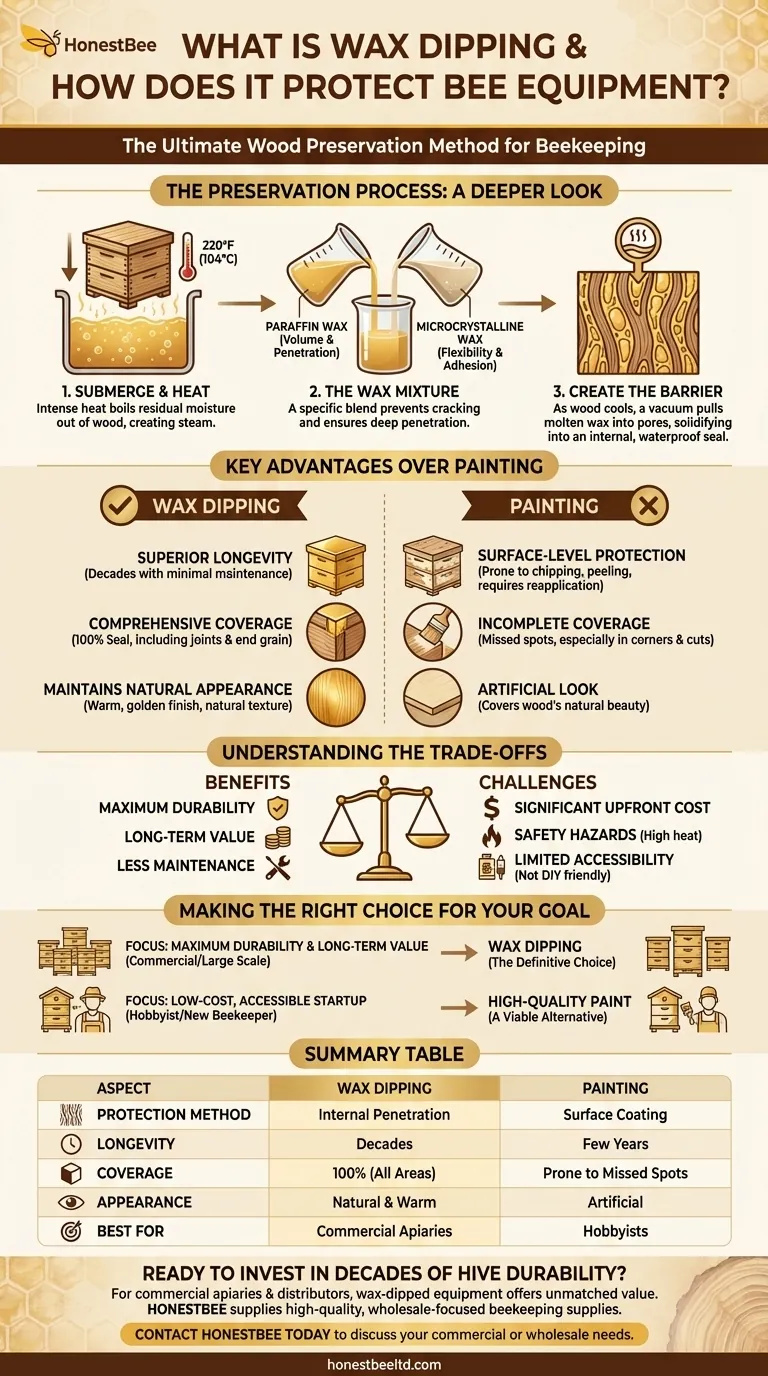

The Preservation Process: A Deeper Look

Understanding the mechanics of wax dipping reveals why it is such an effective method for protecting wooden hive components against the elements for years, or even decades.

The Critical Role of Temperature

The process requires heating the wax to approximately 220°F (104°C). This temperature is deliberately above the boiling point of water (212°F / 100°C).

As the wooden equipment is submerged, the intense heat causes any water trapped within the wood fibers to boil and turn into steam. This steam escapes, effectively purging the wood of moisture.

The Wax Mixture

A specific blend of waxes is used to achieve the best results. The most common mixture consists of paraffin and microcrystalline wax.

Paraffin provides the bulk of the volume and penetrates deeply into the wood. The addition of microcrystalline wax improves the flexibility and adhesive properties of the mixture, preventing it from becoming brittle and cracking in fluctuating temperatures.

How It Creates a Barrier

Once the moisture has been driven out, a vacuum effect pulls the molten wax deep into the wood's pores and fibers.

When the equipment is removed and cools, the wax solidifies within the wood structure. This creates an internal, waterproof barrier that physically prevents moisture from re-entering, which is the primary cause of rot, warping, and fungal growth.

Key Advantages Over Painting

While painting is a common method for protecting hive bodies, wax dipping offers several distinct advantages that make it a superior choice for long-term apiary management.

Superior Longevity

A properly wax-dipped hive can last for decades with minimal maintenance. Paint, by contrast, sits on the surface and is prone to chipping, peeling, and cracking, requiring regular scraping and reapplication every few years.

Comprehensive Coverage

The dipping process ensures 100% coverage. The molten wax flows into every corner, joint, and crevice, sealing the end grain and internal cuts that are often missed or inadequately covered by a paintbrush.

Maintains Natural Appearance

Wax dipping enhances the natural beauty of the wood, giving it a warm, golden finish. It avoids the artificial look of paint and provides a more natural surface for the bees.

Understanding the Trade-offs

Despite its benefits, wax dipping is not without its challenges. Objectively weighing the downsides is critical before committing to this method.

Significant Upfront Investment

The primary barrier for most beekeepers is cost. The process requires a large, purpose-built heating vat and a substantial quantity of wax, representing a significant initial financial outlay compared to a can of paint and a brush.

Safety and Equipment

Heating a large volume of flammable wax to high temperatures is inherently hazardous. It requires a controlled environment, proper safety precautions, and specialized equipment to be performed safely and effectively.

Accessibility

Due to the cost and safety factors, wax dipping is often not a practical DIY project for a hobbyist with only a few hives. It is typically performed by commercial beekeepers or specialized service providers.

Making the Right Choice for Your Goal

Your decision should be based on the scale of your operation, your budget, and your long-term goals.

- If your primary focus is maximum durability and long-term value: Wax dipping is the definitive choice, especially for moderate to large-scale operations where the investment is justified by decades of service life.

- If your primary focus is a low-cost, accessible startup: Applying multiple coats of high-quality, exterior-grade paint is a perfectly viable and more manageable alternative for new or hobbyist beekeepers.

Ultimately, choosing your protection method is a strategic decision that balances upfront investment against the promise of long-term durability.

Summary Table:

| Aspect | Wax Dipping | Painting |

|---|---|---|

| Protection Method | Penetrates wood fibers internally | Surface-level coating |

| Longevity | Decades with minimal maintenance | Requires reapplication every few years |

| Coverage | 100%, including joints and end grain | Prone to missed spots and peeling |

| Appearance | Natural, warm wood finish | Artificial, painted look |

| Best For | Commercial apiaries, long-term value | Hobbyists, low-cost startup |

Ready to Invest in Decades of Hive Durability?

For commercial apiaries and beekeeping equipment distributors, the long-term value of wax-dipped equipment is unmatched. It drastically reduces replacement costs and maintenance time, protecting your investment for years to come.

HONESTBEE supplies the high-quality, wholesale-focused beekeeping supplies and equipment you need to build a resilient operation. Our experts can help you select the right products for maximum hive protection.

Contact HONESTBEE today to discuss your commercial or wholesale needs and secure your apiary's future.

Visual Guide

Related Products

- HONESTBEE Classic Pry Bar Hive Tool with High Visibility Finish for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Drop-Style Hive Handles for Beekeeping

- Professional Cotton Beekeeper Suit with Round Veil Design for Commercial Apiaries

- Professional Grade Foldable Beehive Handles

People Also Ask

- What is the use of hive tool in beekeeping? The Essential Multi-Tool for Every Beekeeper

- What are the uses of a hive tool in beekeeping? The Essential Multi-Purpose Key for Your Apiary

- What are the different end shapes found on hive tools? Master Beekeeping with the Right Gear

- What factors should be considered when choosing a hive tool? Select the Right Tool for Your Apiary

- What are the common types of hive tools? Discover the Best Designs for Efficient Apiary Management