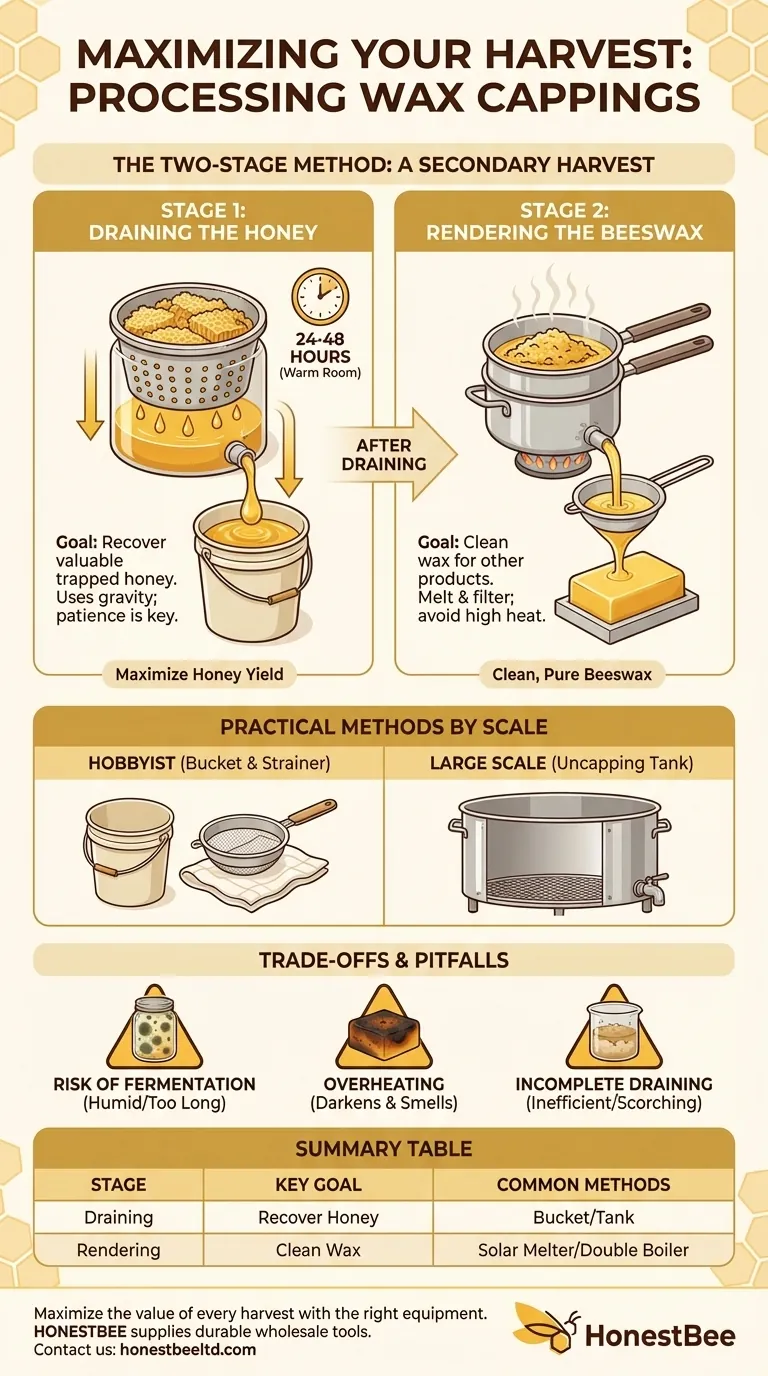

After uncapping your honey frames, the wax cappings should be collected and processed in a two-stage method. First, allow the cappings to drain thoroughly to recover all the valuable honey trapped within them. Second, melt and filter the drained wax to clean it for use in other products like candles, balms, or soaps.

The central principle is to treat wax cappings not as waste, but as a secondary harvest. A systematic process of draining the honey and then rendering the wax ensures you capture the full value of both of these precious hive products.

The Two-Stage Recovery Process

Properly handling wax cappings involves separating two distinct resources: the honey and the beeswax. Rushing this process leads to waste, while a patient approach maximizes your yield.

Stage 1: Draining the Honey

The immediate goal after uncapping is to recover the significant amount of honey that clings to and is trapped within the wax cappings. This honey is of the same quality as your main harvest.

The most common method is to place the cappings in a container that allows honey to drain via gravity. This can be as simple as a food-grade bucket fitted with a strainer or as specialized as a dedicated uncapping tank.

Stage 2: Rendering the Beeswax

Once the honey has been drained, the remaining wax is ready to be cleaned, a process known as rendering. This involves melting the wax to separate it from any remaining impurities like honey residue, propolis, or other hive debris.

The melted wax is then filtered through a fine mesh or cheesecloth to produce a clean, pure block of beeswax. This final product is highly sought after for a wide range of applications.

Practical Methods for Processing Cappings

The equipment you use depends on the scale of your operation, but the principles remain the same.

The Bucket and Strainer Method

For hobbyists, the most straightforward setup involves a food-grade bucket with a paint strainer bag, cheesecloth, or a coarse metal sieve placed over the top. The cappings are placed in the strainer, and honey drips into the bucket below.

Using an Uncapping Tank

Larger operations often use a dedicated uncapping tank. These tanks are typically stainless steel and feature a perforated grid or screen at the bottom that holds the cappings while allowing honey to collect in a reservoir below, often equipped with a spigot or honey gate for easy draining.

The Importance of Warmth and Patience

The rate of draining is highly dependent on temperature. Placing your draining setup in a warm room (but not hot enough to melt the wax) will significantly speed up the process by reducing the honey's viscosity.

Allow at least 24 to 48 hours for the cappings to drain completely. Patience here directly translates to a larger honey yield and cleaner wax for the next stage.

Understanding the Trade-offs and Pitfalls

While the process is simple, a few common mistakes can compromise the quality of your honey or wax.

Risk of Fermentation

The thin film of honey on the wax cappings has a high surface area. If left to drain for too long in a humid environment, this honey can absorb moisture from the air and begin to ferment, ruining its flavor.

Overheating the Beeswax

When rendering the wax, using excessive heat can darken it and give it a burnt smell, reducing its quality and value. Always use a gentle heat source, such as a solar melter or a double boiler, to melt the wax slowly.

Incomplete Draining

Moving on to rendering the wax before it has fully drained is inefficient. The excess honey will mix with the melted wax, making the filtering process more difficult and potentially scorching during heating, which will discolor the final wax block.

Making the Right Choice for Your Goal

Your approach should be guided by the scale of your operation and your primary objective.

- If you are a hobbyist with a few hives: A simple bucket-and-strainer system is perfectly adequate for draining, followed by rendering the wax in a dedicated pot or double boiler.

- If you manage a larger apiary: Investing in an uncapping tank will significantly streamline the process and handle the larger volume of cappings more efficiently.

- If your primary focus is maximizing honey yield: Be patient and allow the cappings to drain for at least 24-48 hours in a warm room before you even consider processing the wax.

- If your primary focus is high-quality beeswax: After a thorough draining, a quick rinse of the cappings with cool water can remove residual honey, preventing it from scorching and discoloring your wax during the melting phase.

By treating your wax cappings with methodical care, you transform a messy byproduct into two of the hive's most valuable resources.

Summary Table:

| Processing Stage | Key Goal | Common Methods |

|---|---|---|

| Stage 1: Draining | Recover trapped honey | Bucket & strainer, Uncapping tank |

| Stage 2: Rendering | Clean wax for reuse | Solar melter, Double boiler |

Maximize the value of every harvest with the right equipment.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused tools needed for efficient large-scale operations—from uncapping tanks to filtering supplies. Let us help you streamline your post-harvest processing and boost your profitability.

Contact our experts today to discuss your apiary's needs.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business