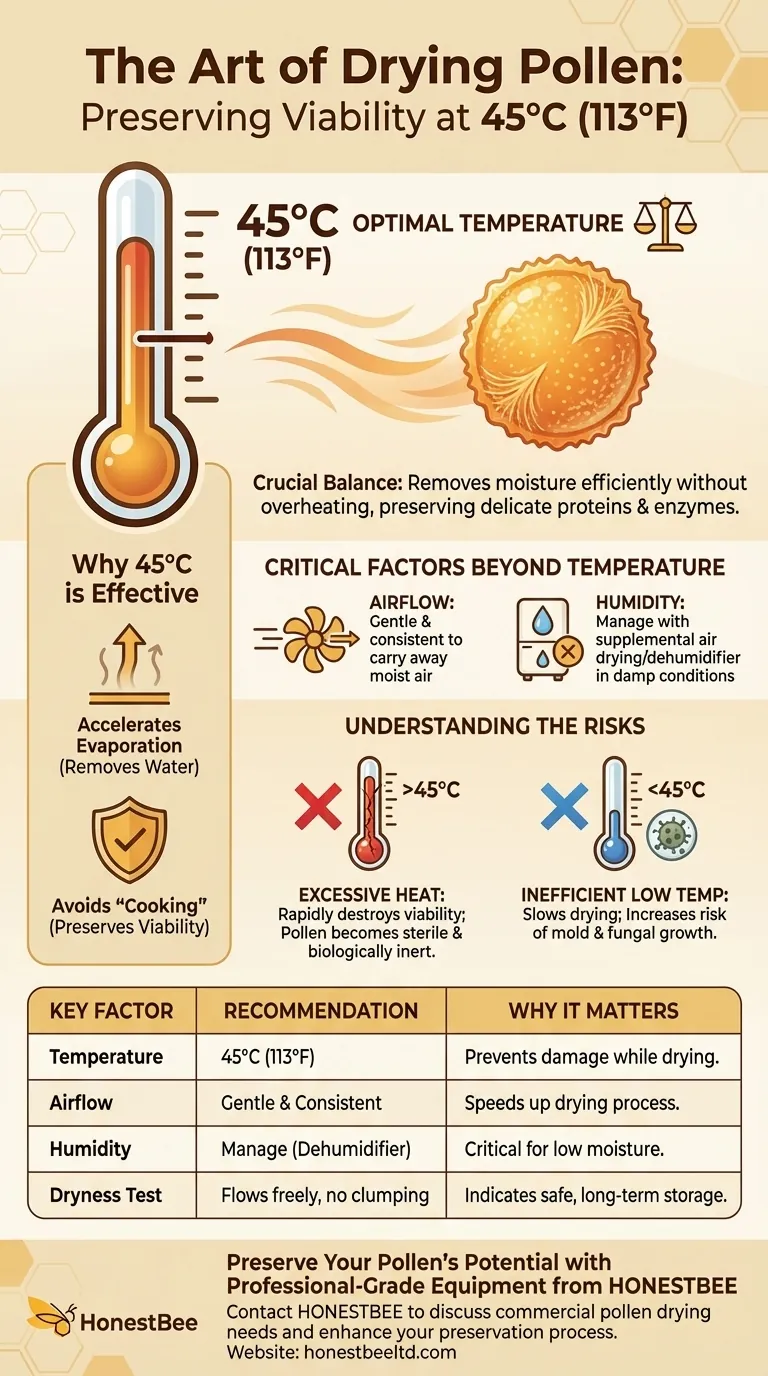

To dry pollen effectively while preserving its viability, the recommended temperature is 45°C (113°F). This specific temperature provides an optimal balance, ensuring moisture is removed efficiently without overheating and damaging the delicate biological material. In particularly humid conditions, supplemental air drying may be required to achieve the necessary low moisture content.

The core challenge in drying pollen is not just removing water, but doing so without compromising its biological integrity. The right temperature, combined with proper airflow, is the key to preserving pollen for future use.

The Principle of Pollen Preservation

The primary goal of drying pollen is to reduce its moisture content significantly. This process inhibits the growth of mold and bacteria and places the pollen into a dormant state, preserving its viability for storage and later application.

The Recommended Temperature Benchmark

The industry standard of 45°C (113°F) is the most widely accepted temperature for drying pollen. This benchmark has been established through research and practice as the ideal point for safe and effective moisture removal.

Why This Temperature is Effective

This temperature is warm enough to accelerate the evaporation of water from the pollen grains. However, it is critically low enough to avoid "cooking" the pollen, which would denature the sensitive proteins and enzymes essential for successful fertilization.

Critical Factors Beyond Temperature

Achieving optimal dryness involves more than just setting a thermostat. The environment in which you are drying the pollen plays a crucial role in the outcome.

The Impact of Humidity

High ambient humidity is the primary obstacle to effective drying. If the surrounding air is already saturated with moisture, it cannot efficiently absorb more from the pollen. This is why additional air drying or using a dehumidifier may be necessary in damp climates.

The Importance of Airflow

Gentle, consistent airflow is essential. Air circulation serves to carry away the moist air that forms directly around the pollen, replacing it with drier air that can continue the evaporation process. Without it, the pollen can remain damp even at the correct temperature.

Understanding the Risks

Deviating from the recommended temperature and process can have significant consequences, potentially rendering your entire collection effort useless.

The Danger of Excessive Heat

Exceeding the 45°C (113°F) threshold, even for a short period, can rapidly destroy the pollen's viability. The heat essentially sterilizes the pollen grains, making them incapable of fertilization. The pollen may appear perfectly dry, but it will be biologically inert.

The Inefficiency of Low Temperatures

Using a temperature that is too low significantly slows down the drying process. This prolonged exposure to moisture, especially in humid conditions, dramatically increases the risk of mold and fungal growth, which will spoil the pollen before it is fully preserved.

Applying This to Your Process

Your specific setup will determine how you apply these principles to achieve the best results for your pollen collection.

- If your primary focus is maximum viability: Strictly adhere to the 45°C (113°F) temperature limit and ensure constant, gentle airflow across the pollen.

- If your primary focus is drying in a humid environment: Supplement your heating with a dehumidifier or a continuous air-drying step to combat high ambient moisture.

- If your primary focus is confirming dryness: The pollen is sufficiently dry when it flows freely like fine, dry sand and no longer clumps together.

By carefully controlling temperature and airflow, you ensure the preservation of your pollen's vital potential.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Temperature | 45°C (113°F) | Prevents damage to proteins and enzymes while effectively removing moisture. |

| Airflow | Gentle & Consistent | Carries away moist air, speeding up the drying process. |

| Humidity | Manage with Dehumidifier/Air Drying | Critical in damp environments to achieve low moisture content. |

| Dryness Test | Flows freely, no clumping | Indicates sufficient dryness for safe, long-term storage. |

Preserve Your Pollen's Potential with Professional-Grade Equipment from HONESTBEE

For commercial apiaries and beekeeping equipment distributors, achieving consistent, high-quality pollen preservation is non-negotiable. The precise temperature control and effective airflow detailed in this article are only possible with reliable equipment.

HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment you need to scale your operations with confidence. Ensure every batch of pollen retains its maximum viability for storage and sale.

Contact HONESTBEE today to discuss your commercial pollen drying needs and discover how our products can enhance your preservation process.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE Professional Cabinet Bottle Dryer

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- How does a vacuum rotary evaporator contribute to the recovery of bee pollen extracts? Protect Bioactive Integrity

- Why is pollen collected using pollen traps? A Strategic Guide to Boosting Colony Health and Growth

- How does the design of comb rake blades benefit bee pollen drying? Maximize Quality with Active Agitation Technology

- What is the purpose of installing pollen traps? Enhancing Botanical Survey Accuracy and Colony Health

- What is the ideal type of colony for pollen collection? Optimize Your Harvest with Strong Hives

- What is the recommended duration for keeping a pollen trap on a hive? Protect Your Colony's Health

- Why is regular cleaning and disinfection of pollen traps critical? Ensure Food Safety in Bee Pollen Harvesting

- What is the operational mechanism of pollen traps? Essential Guide for Honeybee Pollen Collection and Monitoring