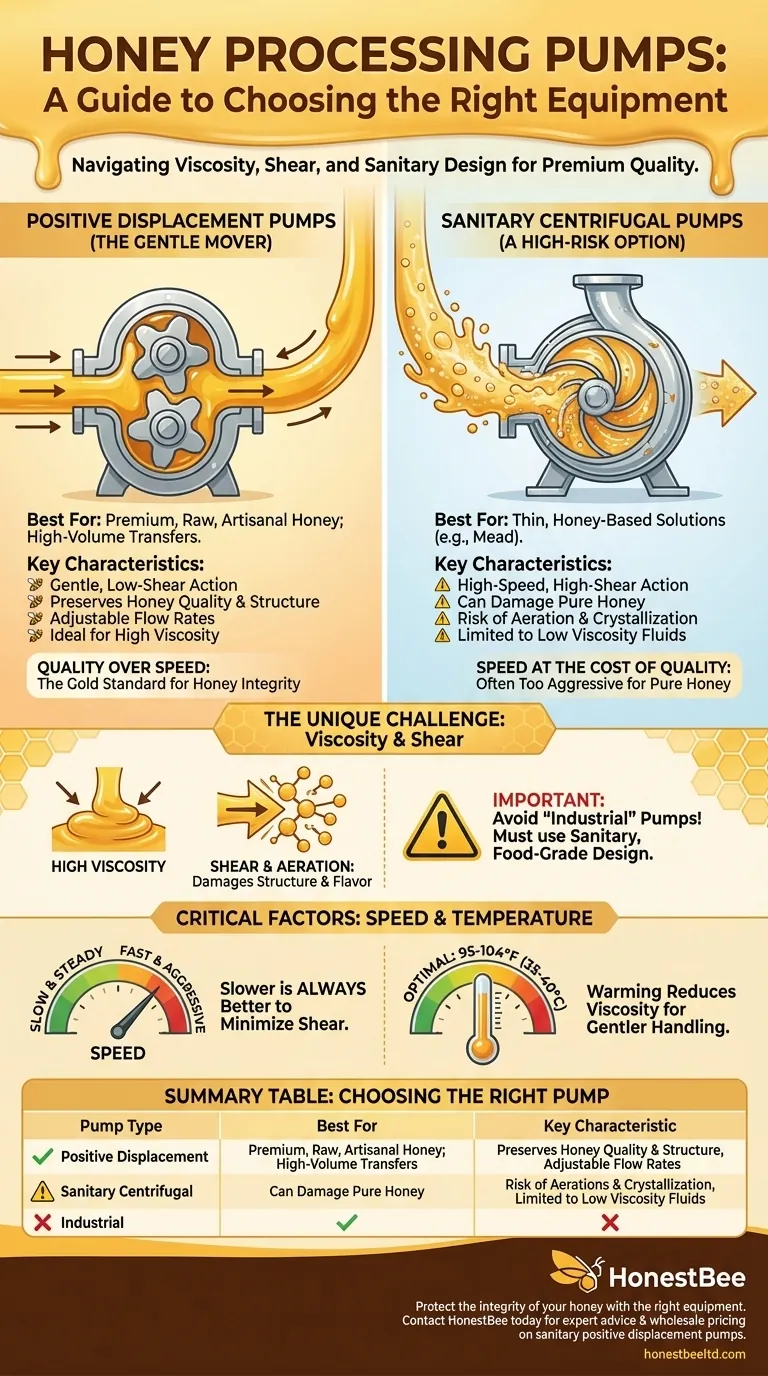

For honey processing, the primary options are positive displacement pumps and sanitary centrifugal pumps. Positive displacement pumps are generally the superior choice for moving viscous, delicate honey, while centrifugal pumps may have limited application for less viscous honey-related fluids.

The central challenge in pumping honey is not simply moving it, but doing so without causing damage from high shear or aeration. The right choice depends entirely on prioritizing honey quality, which almost always favors a gentle, low-speed positive displacement pump.

The Unique Challenge of Pumping Honey

Honey is not like water. Its high viscosity (resistance to flow) and delicate chemical structure make it uniquely challenging to handle with mechanical equipment.

Understanding Viscosity and Shear

Honey is highly viscous. This means it requires significant force to move, especially when cool.

Pumping creates shear, which is a force that can physically break down the delicate structures and enzymes within honey. Aggressive pumping can also introduce air, leading to crystallization and oxidation, which degrades quality.

The Importance of a "Sanitary" Design

Any equipment that comes into contact with honey must be of a sanitary design. This means it is made from food-grade materials (like stainless steel), has smooth surfaces, and can be easily and completely disassembled for cleaning to prevent bacterial growth.

A Breakdown of Honey Pump Types

The two main categories of sanitary pumps used in food processing have very different mechanisms and are not equally suited for honey.

Positive Displacement Pumps: The Gentle Mover

Positive displacement (PD) pumps are the workhorse for high-quality honey processing. They work by trapping a fixed amount of honey in a cavity and then forcing (displacing) it through the outlet.

Common types of PD pumps include lobe, gear, or progressive cavity pumps. Their key advantage is a slow, steady, and gentle action that minimizes shear, preserving the honey's delicate structure and quality.

Sanitary Centrifugal Pumps: A High-Risk Option

Centrifugal pumps use a rapidly spinning impeller to throw liquid outward by centrifugal force. This high-speed action is excellent for moving low-viscosity fluids like water or milk.

For pure, viscous honey, this high-speed mechanism is often too aggressive. It can easily cause excessive shear and aerate the honey, effectively "beating" it and damaging its quality. Their use is typically limited to moving much less viscous honey-water solutions.

A Note on "Industrial" Pumps

The term industrial pump simply refers to a pump designed for general industrial applications, not specifically for food. These pumps are not built to sanitary standards and must not be used for honey processing, as they can introduce contaminants and are impossible to clean properly.

Understanding the Trade-offs

Choosing a pump involves balancing efficiency, cost, and the impact on your final product.

Positive Displacement: Quality Over Speed

PD pumps are the gold standard for preserving honey's integrity. They operate at lower speeds with adjustable flow rates, giving you precise control.

The trade-off is typically a higher initial cost and a slower flow rate compared to centrifugal pumps. However, this investment protects the value of your product.

Centrifugal: Speed at the Cost of Quality

The primary benefit of a centrifugal pump is a high flow rate at a lower cost. However, this comes at a significant risk.

Using a centrifugal pump for viscous honey can degrade its color, flavor, and texture. This makes them unsuitable for any processor whose reputation is built on quality.

The Critical Role of Speed and Temperature

No matter the pump type, slower is always better for honey. Running any pump too fast will increase shear.

Gently warming honey to around 95-104°F (35-40°C) dramatically reduces its viscosity, making it far easier to pump. This reduces stress on both the pump and the honey itself, allowing for lower pump speeds and gentler handling.

Making the Right Choice for Your Operation

Your final decision should be guided by the scale of your operation and your commitment to product quality.

- If your primary focus is premium, raw, or artisanal honey: A positive displacement pump is the only choice to protect the delicate qualities of your product.

- If your primary focus is high-volume commercial processing: You will still rely on positive displacement pumps for most transfers, especially post-filtering and during bottling, to maintain quality standards.

- If you need to move thin, honey-based solutions (e.g., for mead): A sanitary centrifugal pump may be a cost-effective option for these less-viscous liquids.

Ultimately, protecting the integrity of your honey should be the deciding factor in your equipment choice.

Summary Table:

| Pump Type | Best For | Key Characteristic |

|---|---|---|

| Positive Displacement | Premium, raw, or artisanal honey; High-volume transfers | Gentle, low-shear action; Preserves honey quality |

| Sanitary Centrifugal | Thin, honey-based solutions (e.g., mead) | High-speed, high-shear; Can damage pure honey |

| Industrial (Avoid) | Not for food contact; General industrial use | Non-sanitary; Risk of contamination |

Protect the integrity of your honey with the right equipment. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, sanitary positive displacement pumps designed for gentle honey processing. Our wholesale-focused operations ensure you get the reliable equipment you need to maintain your product's premium quality. Contact HONESTBEE today for expert advice and wholesale pricing on beekeeping supplies and equipment.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Professional Honey Storage Tank with Agitation System

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What advantages do specialized Suction Pumps offer compared to traditional methods? Optimize Royal Jelly Extraction

- What are the technical advantages of using vacuum honey suction pumps? Upgrade to Non-Destructive Harvesting

- Who are the typical users of stainless steel screw honey pumps? From Commercial Beekeepers to Hobbyists

- What is the primary function of a portable vacuum pump in suction-style honey harvesting? Enhance Efficiency & Purity

- What are the different types of honey pumps and their respective uses? Choose the Right Tool for Your Apiary

- What role do honey pumps play in the honey processing workflow? Optimize Efficiency and Preserve Quality

- What is the function of an industrial-grade micro diaphragm pump in beehive gas measurement? Ensure Data Precision

- How do peristaltic pumps function in volumetric filling? Precision & Sanitary Solutions for Sensitive Liquids