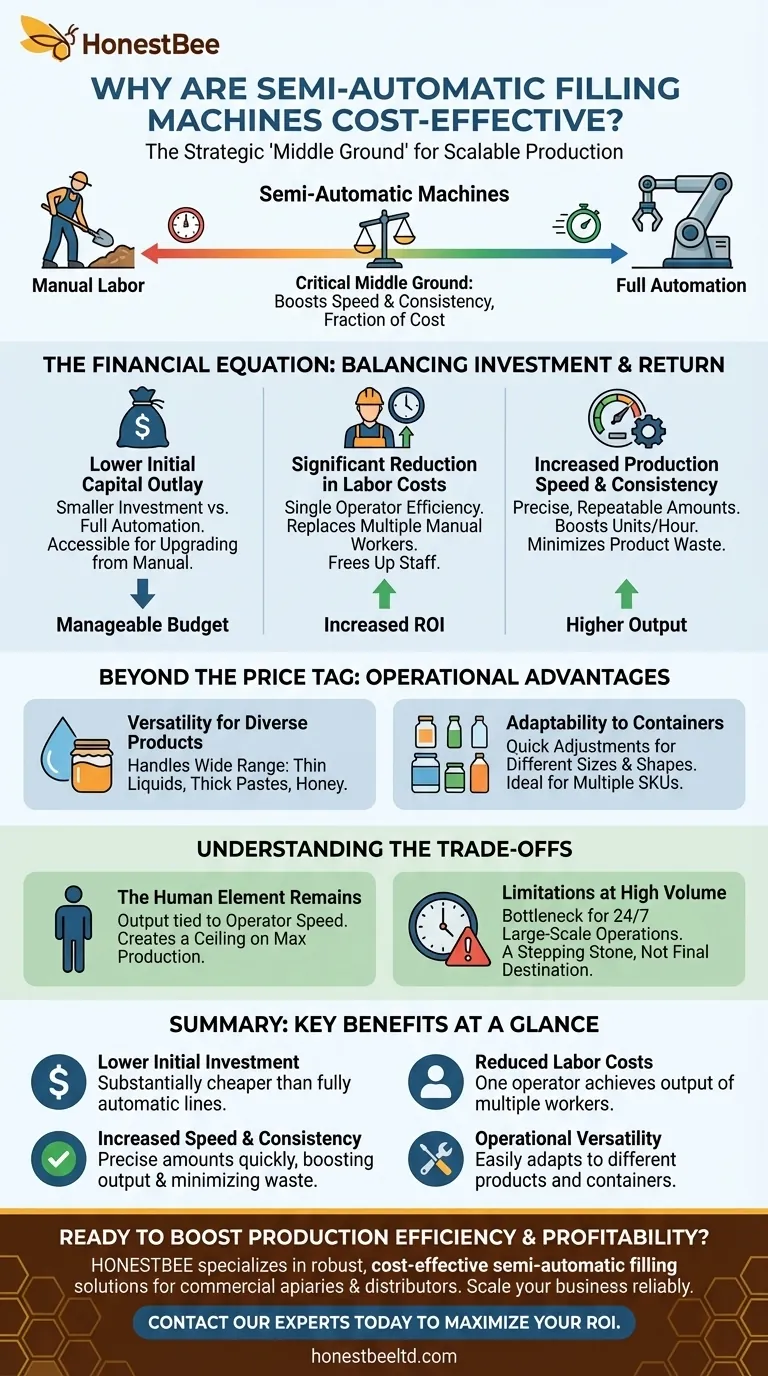

At their core, semi-automatic filling machines are considered cost-effective because they provide a critical middle ground between manual labor and full automation. They offer a significant boost in production speed and consistency for a fraction of the investment required for a fully automatic line, making them an ideal scaling solution for small and medium-sized businesses.

The true cost-effectiveness of a semi-automatic filler isn't just its lower purchase price. It's about maximizing your return on investment by drastically reducing labor costs and product waste while increasing output, all within a manageable budget.

The Financial Equation: Balancing Investment and Return

When evaluating any equipment, the analysis must go beyond the initial sticker price. The cost-effectiveness of a semi-automatic machine is a function of its upfront cost, its impact on operational expenses, and its production output.

Lower Initial Capital Outlay

Compared to their fully automatic counterparts, semi-automatic machines require a substantially smaller initial investment. This makes them accessible to businesses that need to upgrade from manual filling but cannot yet justify the expense of a complete, operator-free production line.

Significant Reduction in Labor Costs

While a semi-automatic machine still requires an operator, it dramatically improves that person's efficiency. A single operator can achieve the output of multiple workers filling by hand, directly reducing payroll costs and freeing up staff for other value-added tasks.

Increased Production Speed and Consistency

These machines dispense a precise, repeatable amount of product with every cycle. This not only increases the number of units you can fill per hour but also minimizes costly product waste from overfills and eliminates inconsistencies common with manual processes.

Beyond the Price Tag: Key Operational Advantages

The financial benefits are supported by powerful operational flexibility, which is especially critical for growing businesses with evolving product lines.

Versatility for Diverse Products

A key advantage is their adaptability. Many semi-automatic fillers can be configured to handle a wide range of product viscosities, from thin liquids to thick pastes and spreads like honey.

Adaptability to Containers

They are also designed for quick adjustments to accommodate various container sizes and shapes. This versatility is invaluable for companies that produce multiple SKUs and need to switch between production runs efficiently.

Understanding the Trade-offs

No solution is perfect for every scenario. True cost-effectiveness means understanding not just the benefits, but also the limitations.

The Human Element Remains

The machine's output is ultimately tied to the speed and consistency of its human operator. This introduces a variable that full automation eliminates and creates a ceiling on maximum production speed.

Limitations at High Volume

For large-scale, 24/7 operations, a semi-automatic machine will inevitably become a bottleneck. It is a stepping stone, not the final destination for businesses aiming for mass-market production levels.

Making the Right Choice for Your Goal

To determine if a semi-automatic filler is the right investment, align its capabilities with your primary business objective.

- If your primary focus is moving away from manual filling: A semi-automatic machine is your most cost-effective next step for boosting speed and professionalism.

- If your primary focus is managing a diverse product line with frequent changeovers: The versatility and lower cost of these machines offer a superior return on investment over more rigid, expensive systems.

- If your primary focus is maximizing output for a single, high-volume product: You should carefully analyze if your volume justifies the leap to a fully automatic system to remove the operator bottleneck.

Ultimately, choosing a semi-automatic filling machine is a strategic investment in controlled, manageable growth.

Summary Table:

| Key Benefit | Description |

|---|---|

| Lower Initial Investment | Substantially cheaper than fully automatic lines, making it accessible for scaling businesses. |

| Reduced Labor Costs | One operator achieves the output of multiple manual workers, cutting payroll expenses. |

| Increased Speed & Consistency | Dispenses precise amounts quickly, boosting output and minimizing product waste. |

| Operational Versatility | Easily adapts to different product viscosities and container sizes for diverse production runs. |

Ready to boost your production efficiency and profitability?

At HONESTBEE, we specialize in supplying robust and versatile beekeeping supplies and equipment, including semi-automatic filling solutions perfect for commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable, cost-effective equipment you need to scale your business.

Contact our experts today to find the ideal filling machine for your operation and start maximizing your ROI.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Honey Frame Uncapper Machine for Beekeeping

- Stainless Steel Triangle Support Honey Strainer and Filters

- Lightweight Plastic Uncapping Roller with Tines

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- How do automated filling and packaging machines contribute to the market value of honey products? Boost Retail Profits

- What additional support is available for selecting a honey packaging machine? Get Expert Guidance for Your Apiary

- How does industrial honey-filling machinery support sustainable beekeeping? Secure Your Commercial Apiary's Future

- What are the main types of honey filling machines? Expert Guide to Choosing the Best Equipment

- How do automated honey filling machines maintain product stability? Expert Secrets to Preserving Honey Quality

- Why is high-capacity honey filling machinery necessary for Giant Honey Bees? Solve the Apis dorsata Volume Crisis

- How do industrial honey-filling machines maintain the quality of honey? 5 Key Technologies for Pure Product Integrity

- How does automation in filling machinery contribute to consistent product quality? Boost Precision & Brand Reliability