To reduce the moisture content of honey, you must encourage evaporation by increasing the honey's surface area and exposing it to dry air. This is most commonly achieved by placing the honey in a sealed room with a dehumidifier or by using controlled, gentle heat to speed up the process over several days. Accurately measuring the moisture level with a refractometer before and during this process is essential.

The core challenge in reducing honey moisture is removing water without damaging the honey's delicate enzymes and flavor. The solution is not simply heat, but creating a moisture imbalance where water is gently drawn from the honey into drier, surrounding air.

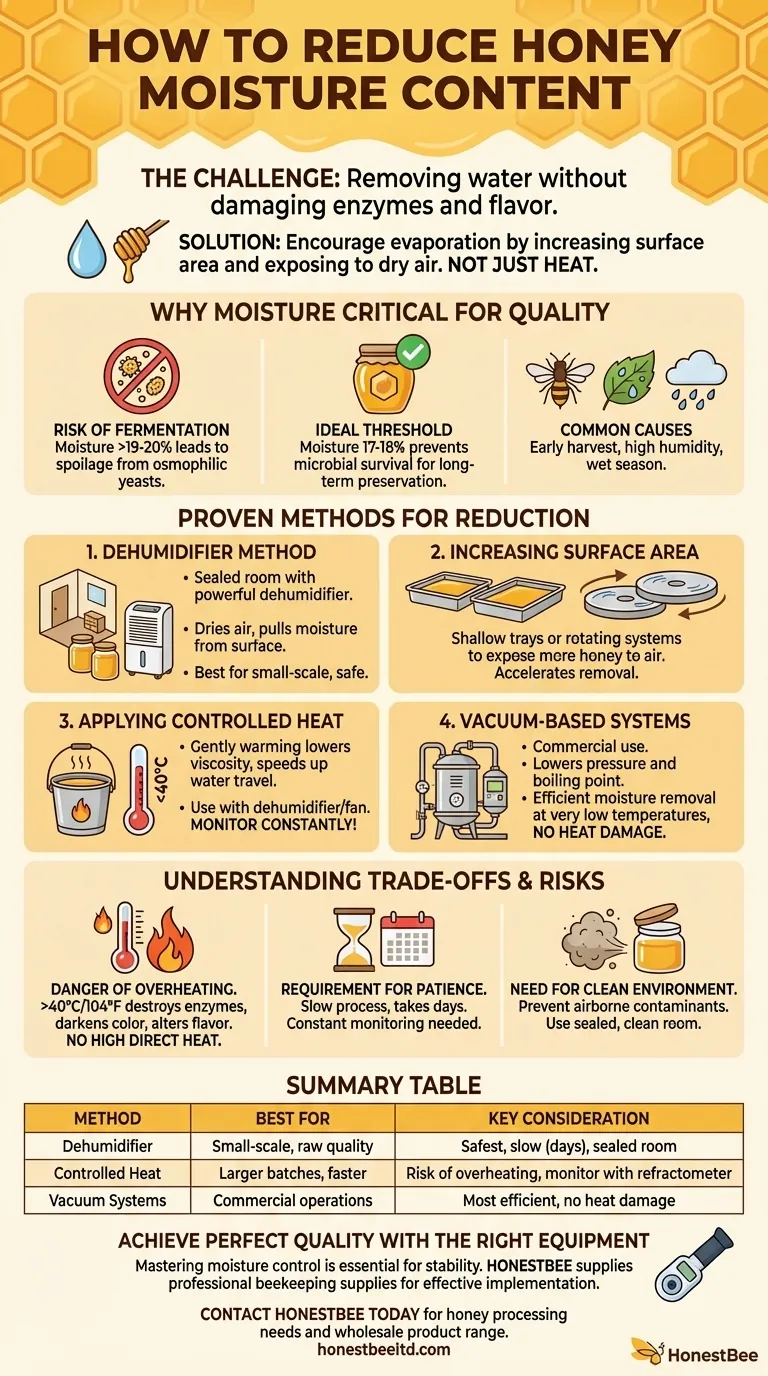

Why Moisture Content is Critical for Honey Quality

Before adjusting moisture levels, it's crucial to understand why it matters. The water percentage in honey is the single most important factor determining its shelf life and quality.

The Risk of Fermentation

Honey with a moisture content above 19-20% is at high risk of fermentation. Naturally occurring osmophilic yeasts in the honey can become active in this higher water environment, consuming the sugars and producing alcohol and carbon dioxide, which spoils the honey.

The Ideal Moisture Threshold

The ideal moisture content for honey is between 17% and 18%. At this level, the high sugar concentration creates an environment where yeast and other microbes cannot survive, ensuring the honey is stable for long-term preservation.

Common Causes of High Moisture

High moisture content can occur for several reasons. These include harvesting honey too early before the bees have had a chance to dehydrate it, high humidity in the local climate, or a particularly wet spring season.

Proven Methods for Reducing Honey Moisture

All successful methods rely on one of two principles: increasing the honey's exposure to dry air or gently lowering its viscosity with heat to release water more easily.

The Dehumidifier Method

For small-scale beekeepers, this is the most reliable and safest method. Place your open honey containers in a small, sealed room with a powerful dehumidifier. The dehumidifier dries the air, and the dry air, in turn, pulls moisture from the honey's surface.

Increasing Surface Area

To accelerate moisture removal, you need to expose more of the honey to the air. This can be achieved by placing the honey in shallow trays or using systems with rotating discs, cones, or wire mesh that the honey flows over in a thin film.

Applying Controlled Heat

Gently warming honey with tools like a bucket heater lowers its viscosity, making it easier for water molecules to travel to the surface and evaporate. This speeds up the drying process, especially when combined with a dehumidifier or fan to move the moist air away.

Vacuum-Based Systems

In commercial operations, vacuum tanks are used to reduce moisture at very low temperatures. The vacuum lowers the atmospheric pressure, which in turn lowers the boiling point of water, allowing it to be removed efficiently without heating the honey.

Understanding the Trade-offs and Risks

While reducing moisture is necessary, performing the process incorrectly can do more harm than good.

The Danger of Overheating

This is the single greatest risk. Excessive heat (typically above 40°C or 104°F) will destroy the beneficial enzymes in raw honey, darken its color, and can negatively alter its delicate flavor profile. Never use high, direct heat.

The Requirement for Patience

Except for industrial vacuum systems, reducing honey moisture is a slow process. The dehumidifier method can take several days to lower the content by just a few percentage points. It requires patience and consistent monitoring.

The Need for a Clean Environment

Exposing honey to open air for extended periods can introduce dust, lint, or other airborne contaminants. Always perform the drying process in a clean, sealed room to protect the final product.

Making the Right Choice for Your Goal

Your approach should be determined by your scale of operation and your primary goals.

- If your primary focus is preserving raw honey quality on a small scale: Use the dehumidifier method in a sealed room. It's slow but is the safest way to protect the honey's delicate properties.

- If your primary focus is processing efficiency for a larger operation: Invest in dedicated honey drying equipment that combines gentle heat, airflow, and a mechanism for increasing surface area.

- If you must process honey quickly: Combining gentle warming with a bucket heater and a strong dehumidifier is the fastest non-industrial option, but it requires constant monitoring with a refractometer to avoid overheating.

Ultimately, successfully preparing your honey for storage is a hallmark of careful craftsmanship.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Dehumidifier | Small-scale, raw honey quality | Safest method; requires a sealed room and patience (several days) |

| Controlled Heat | Faster processing for larger batches | Risk of overheating (>40°C / 104°F); must be monitored with a refractometer |

| Vacuum Systems | Commercial-scale operations | Most efficient; removes moisture at low temperatures without heat damage |

Achieve Perfect Honey Quality with the Right Equipment

Mastering honey moisture control is essential for commercial apiaries and distributors to ensure product stability and prevent spoilage. HONESTBEE supplies the professional beekeeping supplies and equipment you need to implement these methods effectively and at scale.

We provide durable, reliable solutions for honey processing, from refractometers for precise moisture measurement to equipment that supports gentle, controlled drying. Let us help you protect your honey's quality and extend its shelf life.

Contact HONESTBEE today to discuss your honey processing needs and explore our wholesale-focused product range.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Stainless Steel Triangle Support Honey Strainer and Filters

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the recommended operating temperature for drying honey? Preserve Quality and Enzymes with Precision Heating

- What is the typical drying performance of the disc dehumidifier-concentrator for honey? Optimize Your Honey Processing

- Why is convective drying equipment with dehumidification recommended for Bee Bread? Preserve Potency with Low Heat

- What techniques can be employed to lower the moisture level of honey? Mastering Effective Drying for Quality Harvests

- What is the role of dehumidifiers in SHB management? Control Humidity to Protect Your Honey Harvest

- What are the main technical components of a condensation honey dryer? Essential Guide to Precision Honey Processing

- Why is specialized dehydration equipment necessary for stingless bee honey? Preserve Quality and Prevent Fermentation

- What is the ease of use of the honey dryer's controller? Master Honey Drying with Intuitive Control