In short, a heating mechanism is essential for managing honey's viscosity. By gently warming the honey, it becomes less thick and flows more like a liquid, which is critical for the speed, accuracy, and quality of the automated filling process. This simple function prevents common problems like inconsistent jar levels, trapped air bubbles, and slow production speeds.

The purpose of a heating mechanism isn't to "cook" the honey, but to temporarily reduce its viscosity. This physical change is the key that unlocks a filling machine's core benefits: efficiency, accuracy, and a professional, bubble-free product appearance.

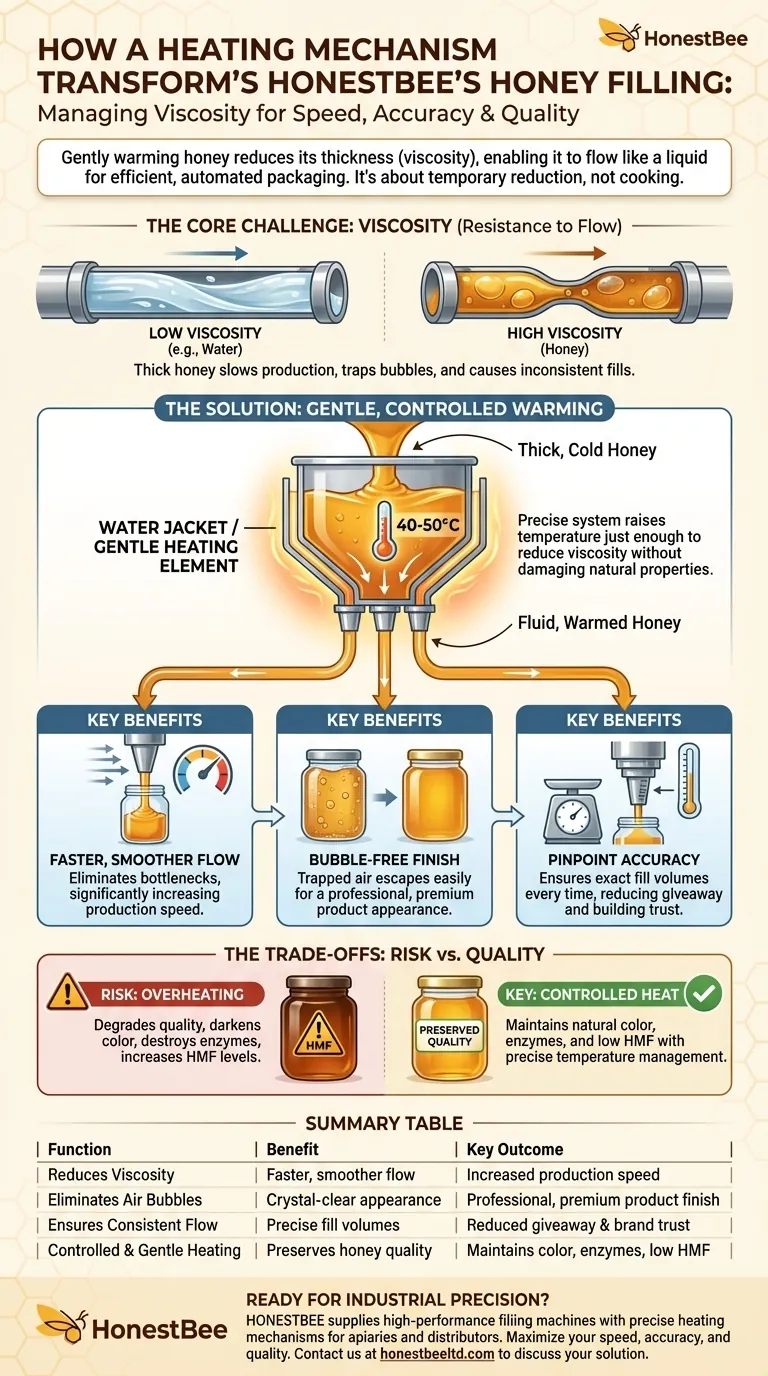

The Core Challenge: Honey's Viscosity

To understand the role of heating, we must first understand the primary obstacle in packaging honey: its natural thickness, or viscosity.

What is Viscosity?

Viscosity is a fluid's resistance to flow. Water has low viscosity and flows easily, while honey has very high viscosity, making it flow slowly and resist movement.

The Consequences of High Viscosity

In an automated filling line, high viscosity causes significant problems. It leads to slow flow rates, which bottleneck production, and makes it difficult to achieve precise, repeatable fill volumes. Most importantly, thick honey tends to trap air bubbles, which compromises the product's appearance and can affect shelf stability.

How a Heating Mechanism Solves the Viscosity Challenge

A well-designed heating system, often integrated into the machine's hopper or tubing, directly counteracts the problems caused by high viscosity.

Facilitating Smooth and Consistent Flow

Slightly warming the honey dramatically reduces its viscosity. This allows it to flow freely and quickly through the machine's nozzles, enabling a much faster and more efficient packaging cycle.

Eliminating Air Bubbles for a Professional Finish

As the honey becomes more fluid, trapped air can escape more easily before the filling is complete. This results in a crystal-clear, bubble-free product in the final container, giving it a premium and professional appearance.

Ensuring Pinpoint Filling Accuracy

A fluid, consistent honey stream allows the filling mechanism (whether piston, pump, or other type) to dispense the exact same volume every single time. This eliminates costly over-filling and ensures customers receive a consistent product, building brand trust.

Understanding the Trade-offs

While heating is beneficial, it must be controlled. Improper heating can do more harm than good, which is why the quality of the mechanism is paramount.

The Risk of Overheating

Honey is a delicate natural product. Overheating can degrade its quality, darken its color, and destroy beneficial enzymes. It can also increase the levels of Hydroxymethylfurfural (HMF), a compound used as an indicator that honey has been subjected to excessive heat.

The Importance of Gentle, Controlled Heat

A professional-grade honey filling machine does not simply blast the honey with heat. It uses a precisely controlled system, often a water jacket or gentle heating elements, to raise the temperature just enough to achieve the desired viscosity without damaging the honey's natural characteristics.

Making the Right Choice for Your Goal

The heating mechanism is not just a feature; it is fundamental to the machine's performance.

- If your primary focus is speed and efficiency: A controlled heating system is non-negotiable, as it is the single biggest factor in accelerating the filling process for a viscous product like honey.

- If your primary focus is product quality and appearance: A gentle, precise heating mechanism is critical for achieving a beautiful, bubble-free fill without compromising the honey's natural integrity.

- If your primary focus is versatility: An adjustable heating system allows you to create ideal flow conditions for different honey varieties, from thin, runny types to thick, crystallized ones.

Ultimately, the heating mechanism transforms honey from a challenging, thick substance into a fluid that can be packaged with industrial precision and efficiency.

Summary Table:

| Function | Benefit | Key Outcome |

|---|---|---|

| Reduces Viscosity | Faster, smoother flow | Increased production speed |

| Eliminates Air Bubbles | Crystal-clear appearance | Professional, premium product finish |

| Ensures Consistent Flow | Precise fill volumes every time | Reduced product giveaway & brand trust |

| Controlled & Gentle Heating | Preserves honey's natural quality | Maintains color, enzymes, and low HMF levels |

Ready to achieve industrial precision and efficiency in your honey packaging?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance honey filling machines featuring precisely controlled heating mechanisms. Our wholesale-focused operations ensure you get the reliable equipment you need to maximize your speed, accuracy, and product quality.

Contact HONESTBEE today to discuss your packaging needs and discover the right solution for your operation.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why is the integration of automated honey-filling machines necessary? Scale Your Commercial Honey Production Line

- What is the significance of automated filling and labeling systems in honey quality? Build Consumer Trust with Precision

- How do industrial honey filling machines address the production challenges associated with high-yield honeybee colonies?

- How do automated honey-filling machines improve the honey post-processing stage? Scale Your Apiary Efficiency

- How do automated honey-filling machines ensure product quality? Secure Purity for Organic Honey Production