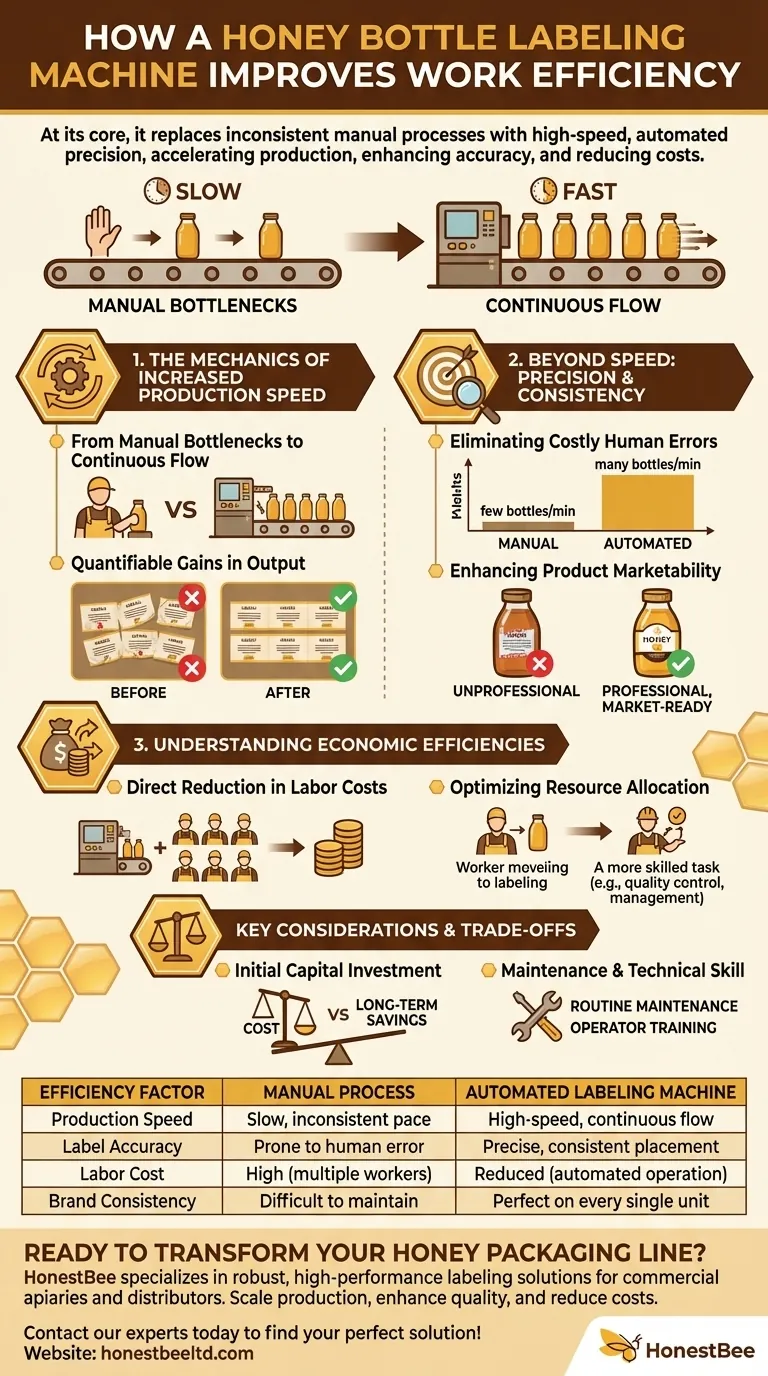

At its core, a honey bottle labeling machine improves work efficiency by replacing inconsistent, labor-intensive manual processes with high-speed, automated precision. This shift not only accelerates the production line but also enhances accuracy and drastically reduces operational costs, leading to a more streamlined and profitable operation.

The true value of a honey bottle labeling machine isn't just in labeling faster; it's in creating a more reliable, cost-effective, and scalable production system by eliminating human error and ensuring brand consistency on every single unit.

The Mechanics of Increased Production Speed

The most immediate impact of an automated labeler is the dramatic increase in throughput. This is achieved by fundamentally changing the mechanics of the labeling process.

From Manual Bottlenecks to Continuous Flow

Manual labeling is inherently a stop-and-go process, limited by the speed and stamina of individual workers. Each bottle requires individual handling, alignment, and application.

An automated machine creates a continuous, uninterrupted flow. Bottles are fed into the system, labeled, and discharged at a consistent and predictable rate, eliminating the bottlenecks associated with manual labor.

Quantifiable Gains in Output

This transition from manual to automated processes enables significantly higher output and faster production rates. Where a person might label a few bottles per minute, a machine can handle a much larger volume, completing in hours what would take days to do by hand.

Beyond Speed: The Impact of Precision and Consistency

While speed is a primary benefit, the improvement in quality and consistency is equally critical for long-term efficiency and brand success.

Eliminating Costly Human Errors

Manual labeling is prone to human error, such as applying labels that are crooked, wrinkled, backward, or incorrectly placed. These mistakes create waste and require costly rework.

A labeling machine uses precise positioning and advanced settings to ensure every label is applied correctly. This consistency minimizes product rejection and material waste, which is a direct efficiency gain.

Enhancing Product Marketability

A perfectly placed, tightly fitted label enhances the overall aesthetic of the product. This professional appearance is not just for looks; it builds consumer trust and strengthens marketability.

Consistent branding across thousands of units is difficult to achieve manually but is a core function of an automated system.

Understanding the Economic Efficiencies

The operational improvements delivered by a labeling machine translate directly into measurable financial gains.

Direct Reduction in Labor Costs

A single automated labeling machine can perform the work of multiple employees. This allows businesses to reduce their reliance on a large manual workforce, saving significantly on wages, training, and supervision expenses.

Optimizing Resource Allocation

By automating the repetitive task of labeling, you can reallocate skilled employees to more complex, value-added roles within the production process. This optimizes your entire human resources investment.

Key Considerations and Trade-offs

Adopting automation is a strategic decision that involves understanding its requirements. While the efficiency gains are clear, it's important to weigh them against the practical realities.

Initial Capital Investment

The most significant factor is the upfront cost of the machine. This investment must be weighed against the projected long-term savings in labor and the reduction of waste.

Maintenance and Technical Skill

Like any piece of machinery, a labeler requires routine maintenance to operate at peak efficiency. Operators may also need training to handle setup, changeovers for different bottle sizes, and basic troubleshooting.

Making the Right Choice for Your Goal

To determine if this is the right investment, align the machine's capabilities with your primary business objective.

- If your primary focus is scaling production: The machine's continuous, high-speed operation is the key to meeting higher demand without a proportional increase in labor.

- If your primary focus is improving brand quality: The machine delivers unmatched consistency and accuracy, ensuring every bottle reflects a professional, market-ready standard.

- If your primary focus is reducing operational costs: The significant reduction in manual labor and the elimination of costly errors provide a clear and direct path to higher profitability.

Ultimately, investing in an automated labeling machine is a strategic move towards a more efficient, competitive, and scalable production process.

Summary Table:

| Efficiency Factor | Manual Process | Automated Labeling Machine |

|---|---|---|

| Production Speed | Slow, inconsistent pace | High-speed, continuous flow |

| Label Accuracy | Prone to human error | Precise, consistent placement |

| Labor Cost | High (multiple workers) | Reduced (automated operation) |

| Brand Consistency | Difficult to maintain | Perfect on every single unit |

Ready to transform your honey packaging line?

As HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with robust, high-performance labeling solutions through our wholesale-focused operations. Our machines are designed to help you scale production, enhance product quality, and significantly reduce operational costs.

Let us help you achieve a more efficient and profitable operation. Contact our experts today to discuss your specific needs and find the perfect labeling solution for your business.

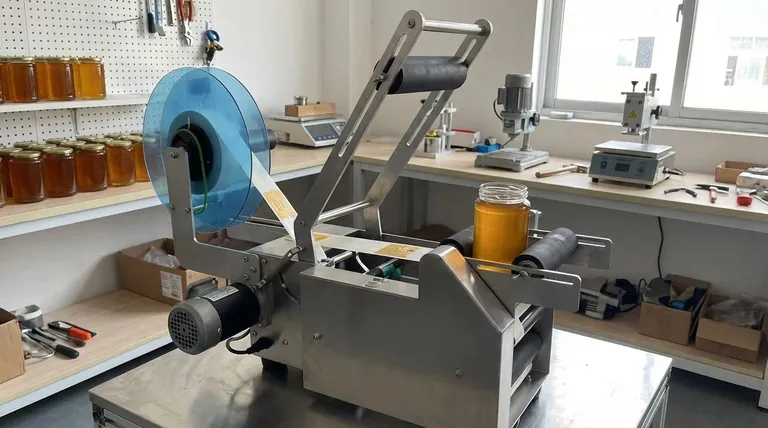

Visual Guide

Related Products

- Semi Automatic Round Bottle Labeling Machine

- Automatic In-Line Round Bottle Labeling Machine

- Squeezable No-Drip Beehive-Shaped Honey Jars with Flip-Top Cap

- 10L Stainless Steel Electric Honey Press Machine

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

People Also Ask

- What role do professional packaging containers and labeling materials play in the market transformation of honey products?

- How do high-precision automatic labeling machines assist in regulatory compliance for bee-derived products?

- What essential information is required on a honey product label? Master FDA Compliance for Your Honey Business

- When is an automatic labeling machine recommended for honey products? Scale Your Production with Precision

- How do professional packaging designs and automated labeling systems facilitate the market entry of honey products?

- What is the technical significance of high-quality brand labels and stickers in honey packaging? Ensure Data Integrity

- How do high-precision labeling and coding machines influence honey consumer trust? Build Brand Integrity and Value

- How do personalized traceability labels and specialized packaging designs contribute to the marketing of urban honey?