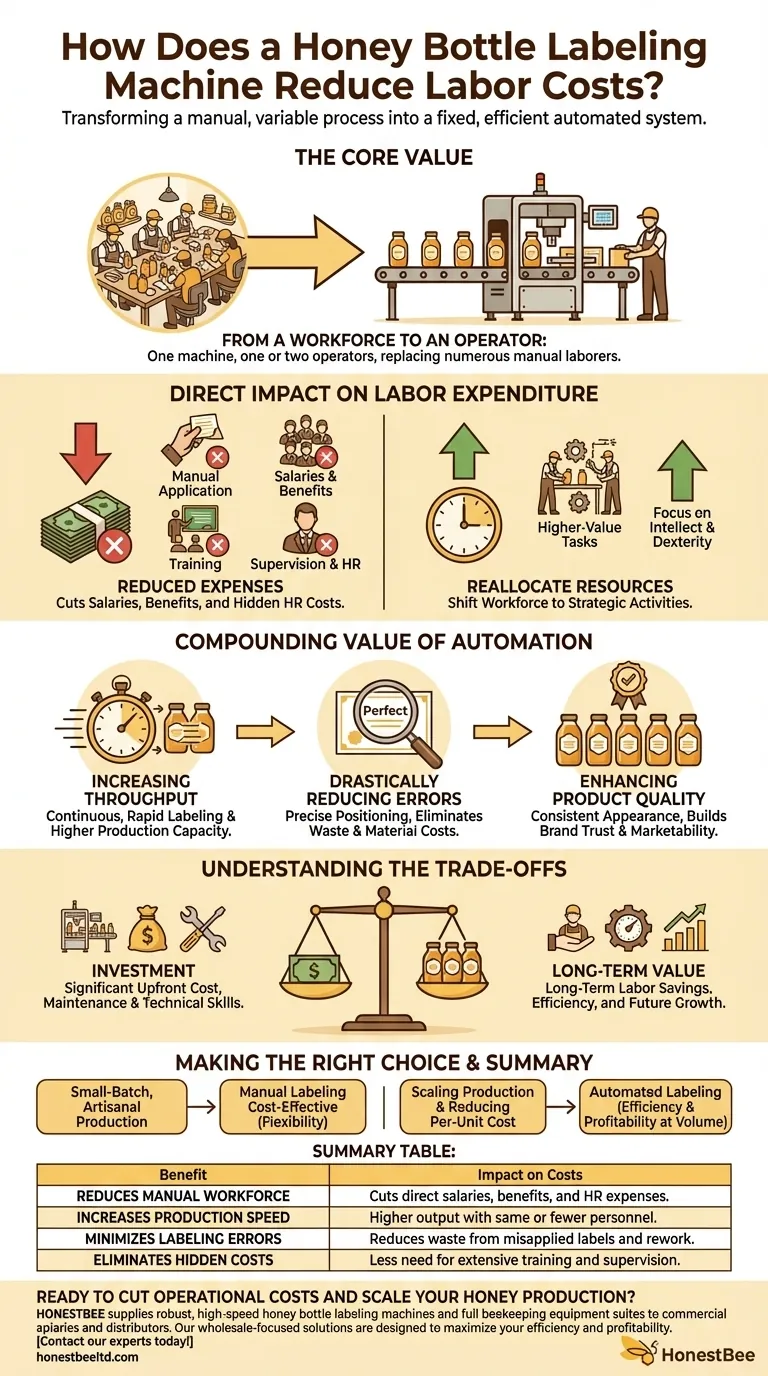

At its core, a honey bottle labeling machine reduces labor costs by automating a task that would otherwise require a significant manual workforce. Instead of employing numerous workers to apply labels by hand, a company can operate the machine with just one or two trained operators, drastically cutting down on salaries, benefits, and associated human resource expenses for the labeling process.

The true value of a labeling machine isn't just in reducing headcount. It's in transforming a variable, error-prone manual process into a fixed, highly efficient automated system that lowers per-unit costs while simultaneously improving product quality.

The Direct Impact on Labor Expenditure

Automating the labeling process provides an immediate and measurable reduction in the most obvious operational expense: direct labor. This is the primary driver for most businesses considering the investment.

From a Workforce to an Operator

The most significant saving comes from the reduction in personnel. A single automatic labeling line can often match or exceed the output of a large team of manual labelers.

This allows a business to reallocate its workforce to higher-value tasks that require human intellect and dexterity, rather than repetitive manual labor.

Eliminating Hidden Labor Costs

Labor cost is more than just salary. A larger manual workforce requires significant investment in training, ongoing supervision, and human resource management.

Automating the process minimizes these ancillary expenses. Training is focused on a few machine operators, and the need for constant quality control supervision on the labeling line is virtually eliminated.

The Compounding Value of Automation

Beyond direct salary savings, automation creates compounding financial benefits by improving efficiency, accuracy, and consistency—all of which have a direct impact on the bottom line.

Increasing Production Throughput

A honey bottle labeling machine enables continuous and rapid labeling, operating at a speed that is impossible to sustain manually.

This increased efficiency means more products are ready for market in less time, boosting overall production capacity and allowing the business to meet higher demand without a proportional increase in costs.

Drastically Reducing Costly Errors

Manual labeling is prone to human error, including misplaced, crooked, or incorrect labels. Each of these mistakes represents wasted materials, lost time, and potentially unsellable product.

Automation provides precise positioning and consistent application, ensuring every bottle is labeled correctly. This reduction in errors directly translates to less waste and lower material costs.

Enhancing Product Quality and Consistency

Perfectly applied labels enhance the aesthetic appeal and perceived quality of the product on the shelf. Consistency across thousands of units builds brand trust and professionalism.

While not a direct labor saving, this improvement in marketability is a crucial financial benefit that supports higher pricing and stronger sales, driven by the machine's reliable performance.

Understanding the Trade-offs

While highly beneficial, investing in a labeling machine is a strategic decision with clear trade-offs that must be considered.

Initial Capital Investment

The primary trade-off is the significant upfront cost of the machinery. This capital expenditure must be weighed against the projected long-term labor savings.

Maintenance and Technical Skill

An automated system introduces new costs, including routine maintenance, potential repairs, and the need for operators with technical skills. These operational expenses replace, rather than eliminate, a budget line item.

Operational Flexibility

Manual labor is inherently flexible. A team of workers can easily switch between different bottle shapes, sizes, and label types with minimal downtime.

Some automated systems may require more time and effort for changeovers, making them less efficient for producers with a wide variety of small-batch products.

Making the Right Choice for Your Operation

Ultimately, the decision to invest depends on your production scale and business goals.

- If your primary focus is small-batch, artisanal production: The flexibility of manual labeling might be more cost-effective than the high initial investment in automation.

- If your primary focus is scaling production and reducing per-unit cost: An automated labeling machine is a critical investment for achieving efficiency and profitability at volume.

Choosing to automate is a strategic move to build a more resilient and efficient production system for future growth.

Summary Table:

| Benefit | Impact on Costs |

|---|---|

| Reduces Manual Workforce | Cuts direct salaries, benefits, and HR expenses. |

| Increases Production Speed | Higher output with the same or fewer personnel. |

| Minimizes Labeling Errors | Reduces waste from misapplied labels and rework. |

| Eliminates Hidden Costs | Less need for extensive training and supervision. |

Ready to cut your operational costs and scale your honey production?

HONESTBEE supplies robust, high-speed honey bottle labeling machines and full beekeeping equipment suites to commercial apiaries and distributors. Our wholesale-focused solutions are designed to maximize your efficiency and profitability.

Contact our experts today to find the perfect labeling automation solution for your business!

Visual Guide

Related Products

- Automatic In-Line Round Bottle Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Squeezable No-Drip Beehive-Shaped Honey Jars with Flip-Top Cap

People Also Ask

- How do honey product packaging and labeling equipment support marketing and traceability? Boost Value and Trust

- What is the significance of professional Packaging and Labeling for honey? Secure Quality and Scale Your Brand

- How does high-resolution automatic labeling equipment support honey brand trust? Boost Transparency & Premium Appeal

- What is the technical significance of terminal product labeling systems? Build Trust in Sustainable Beekeeping

- What is the importance of specialized packaging and labeling consumables in the commercialization of stingless bee honey?

- What are the benefits of using labeling machines? Boost Speed, Accuracy & Brand Image

- How do standardized packaging and labeling equipment support the industrialization of the stingless bee honey market?

- How does an automatic labeling machine operate? Achieve High-Speed, Precise Product Labeling